Seed breaking preventing grape squeezer in wine-making technology

A press and anti-breaking technology, applied in the field of presses, can solve the problems of strong astringency of tannin, increase of cost, damage to wine quality, etc., to improve the pressing effect and work efficiency, soft pressing force, and reduce the rate of broken seeds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

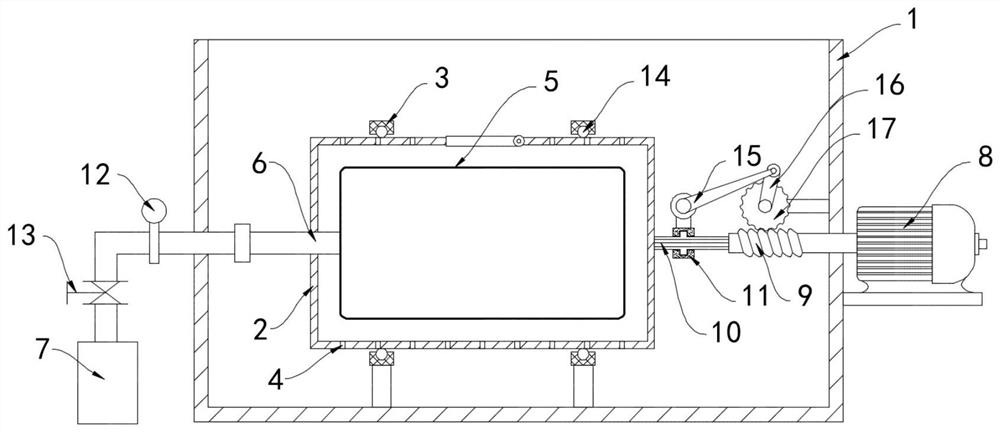

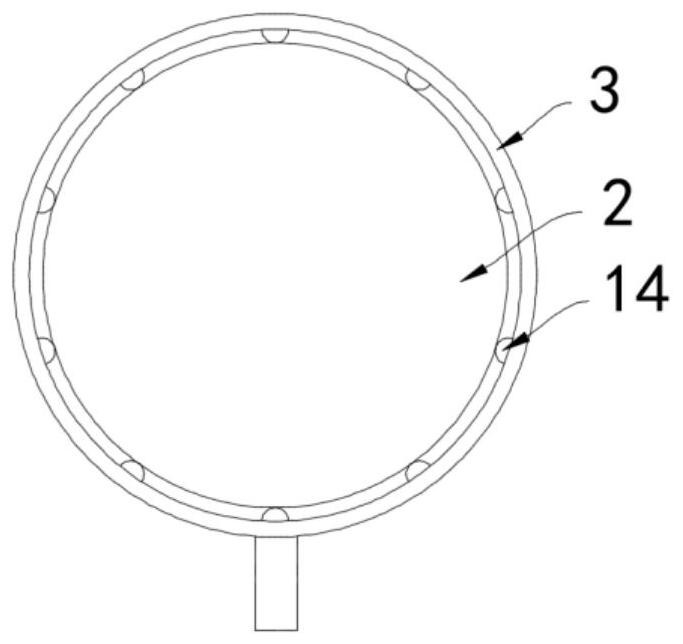

[0019] Such as Figure 1-2 As shown, an anti-broken seed grape press in the winemaking process includes a shell 1 and a squeeze cylinder 2 arranged in the shell 1. The side wall of the squeeze cylinder 2 is hinged with an inlet and outlet door, and the outside of the squeeze cylinder 2 is coaxial. There is a slip ring 3 in the rotation sleeve, and a rolling ball 14 is embedded in the slip ring 3. The ball 14 is rollingly connected with the outer wall of the squeeze barrel 2. The ball 14 greatly reduces the friction between the slip ring 3 and the squeeze barrel 2, ensuring It operates stably, and the lower end of the slip ring 3 is fixed to the bottom surface of the housing 1 through a support rod.

[0020] A plurality of through holes 4 are evenly distributed on the peripheral side wall of the squeeze barrel 2, and a rubber air bag 5 is arranged inside the squeeze barrel 2, and one end of the rubber air bag 5 is fixedly connected with an air pipe 6, and an air pump 7 is insta...

Embodiment 2

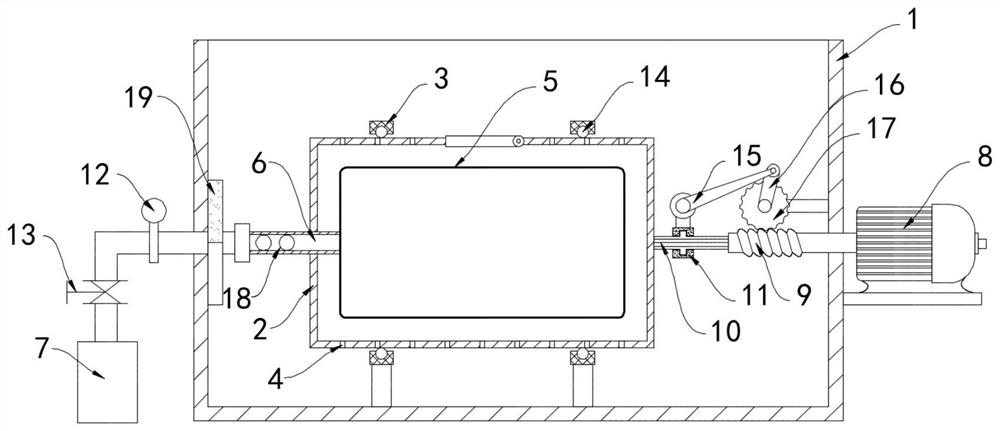

[0025] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the trachea 6 is provided with a guide coil 18, the central axis of the guide coil 18 is perpendicular to the axial direction of the trachea 6, and the side wall of the housing 1 is provided with a bar-shaped magnet19.

[0026] In this embodiment, when the trachea 6 rotates with the squeeze cylinder 2, the conductive coil 18 rotates accordingly. According to the principle of electromagnetic induction, when the magnetic flux in the closed coil changes, an induced current is generated in the closed coil, and the conductive coil 18 rotates. In the process, the magnetic flux produced by the bar magnet 19 in the conductor coil 18 changes moment by moment, then an induced current is generated in the conductor coil 18, and the current is converted into heat energy, which heats the air in the rubber air bag 5, and the air expands when heated, further improving the pressure resistance of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com