Pneumatic shell breaking device for fresh camellia oleifera fruits and camellia oleifera fruit shell breaking machine using device

A shell breaking device and fresh fruit technology, which is applied in the directions of shelling, application, and pod removal, can solve the problems of not completely replacing manual work, reducing the quality of camellia oil, and high labor intensity, and achieving sufficient separation, easy operation, and low The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

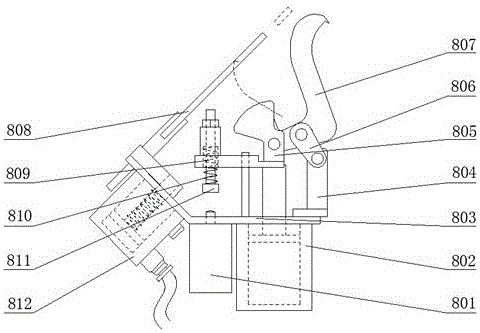

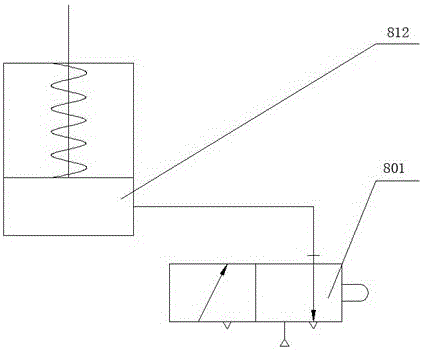

[0025] Such as figure 1 , a pneumatic cracking device for camellia oleifera fresh fruit, comprising a machine base 803 and a finger pressing device, a finger breaking device and a push rod device located on the machine base 803;

[0026] The finger pressing device includes a finger pressing cylinder 802, a finger pressing seat 805, a finger pressing 807, a rocker 806, and a rocking bar seat 804; the finger pressing cylinder 802 is fixed on the base 803, and the air inlet of the cylinder is connected with the air supply pipe , the air outlet is connected to a muffler; the tail end of the pressure finger 807 is hinged with the pressure finger seat 805, and the pressure finger seat 805 is fixedly connected with the top of the piston rod of the pressure finger cylinder 802; the top of the piston rod is located above the machine base 803; One end of the rocker 806 is hinged to the middle of the pressing finger 807, and the other end is hinged to the rocker base 804; the rocker base...

Embodiment 2

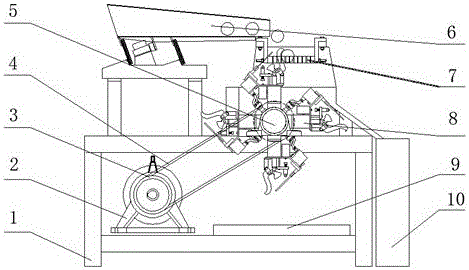

[0034] Such as Figure 2-5 As shown, the structure of camellia oleifera shell breaking machine is shown in patent CN201520913825.2, and the pressing and peeling structure of the previous patent is replaced by this shell breaking device; the specific scheme is as follows:

[0035] Camellia oleifera fruit shelling machine mainly includes frame 1 and three-phase asynchronous motor 2 installed on frame 1, pulley 3, belt 4, pressure stripping roller 5, automatic feeding hopper 6, shell breaking track 7, pneumatic shell breaking Device 8, crushing hopper 9, whole hopper 10. The power output by the three-phase asynchronous motor 2 is transmitted to the peeling roller 5 through the pulley 3 and the belt 4, driving the peeling roller 5 to rotate; the pneumatic shell breaking device 8 is installed on the peeling roller 5 in the circumferential direction; the shell breaking track 7 passes through the connecting mechanism Installed on the frame 1 and above the pneumatic cracking device 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com