Edge-rolling occluding cutter forming process

A molding process and hemming technology, which is applied in the field of hemming and knives forming technology, can solve the problems of not being able to reach 45 degrees, and achieve the effect of reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

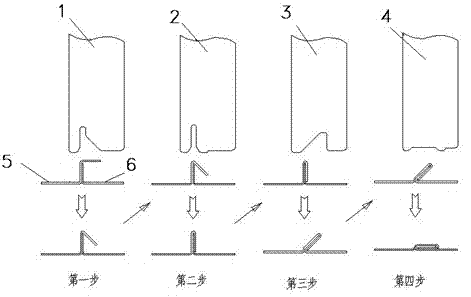

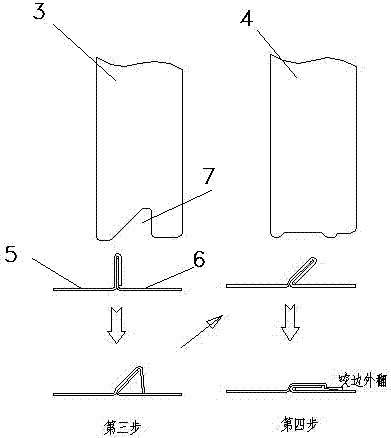

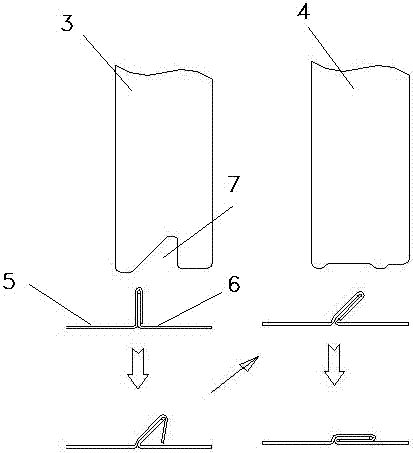

[0010] Depend on figure 1 Shown is the forming process flow of the seaming knives during normal production. Since one side of the knives used in the third step is inclined and the other is straight, when the hob bends the vertical side into a 45-degree inclination, due to The stainless steel plate is elastic, so the free side of the end cover of the dishwasher liner can not reach 45 degrees, sometimes it does not exceed 0 degrees, such as figure 2 As shown, at this time, the undercut edge appears in the fourth step of molding. According to the cause of the problem, it is caused by one side of the end cover of the dishwasher liner being free during the third step of bending. As long as the free edge of the end cover of the dishwasher liner is forced to bend to the left during the bending process, the problem can be solved, such as image 3 As shown, so as long as the straight face of the forming knife edge used in the third step is designed as a bevel, the free edge of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com