Automatic blanking device for breaker screw assembly

A technology of automatic feeding and circuit breaker, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of low production efficiency, unsmooth operation of equipment, and crooked pipelines, etc., and achieves low cost, easy promotion, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

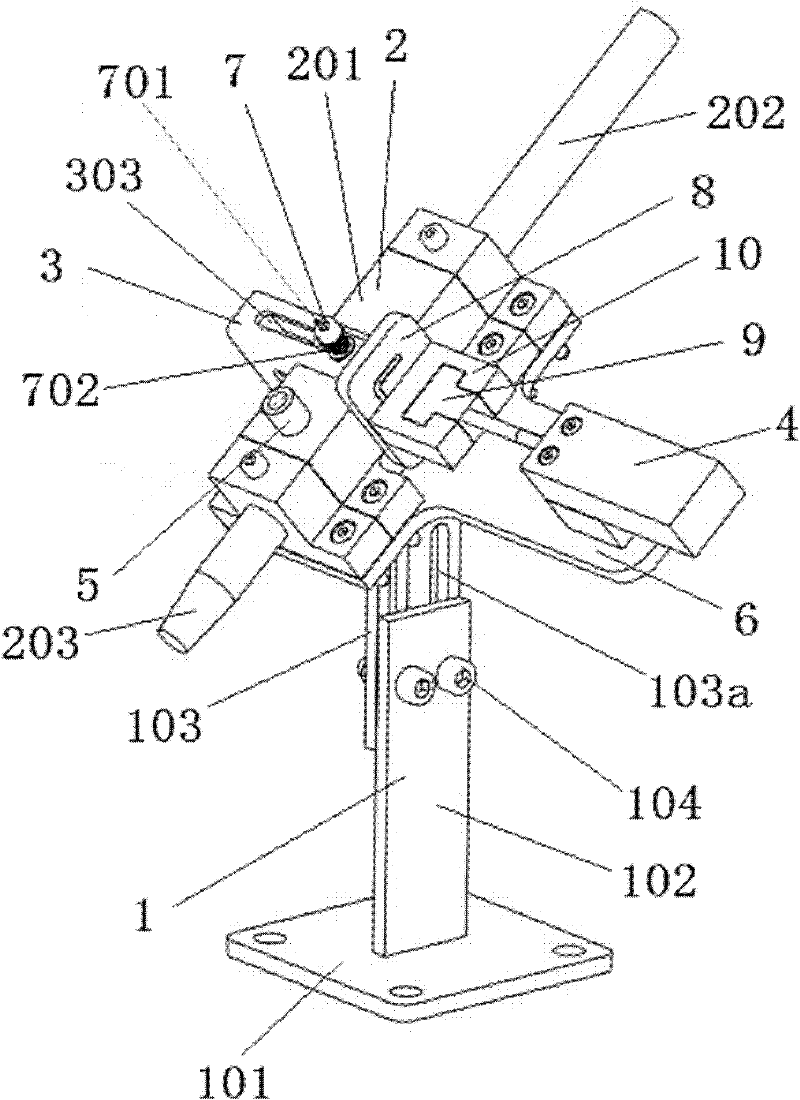

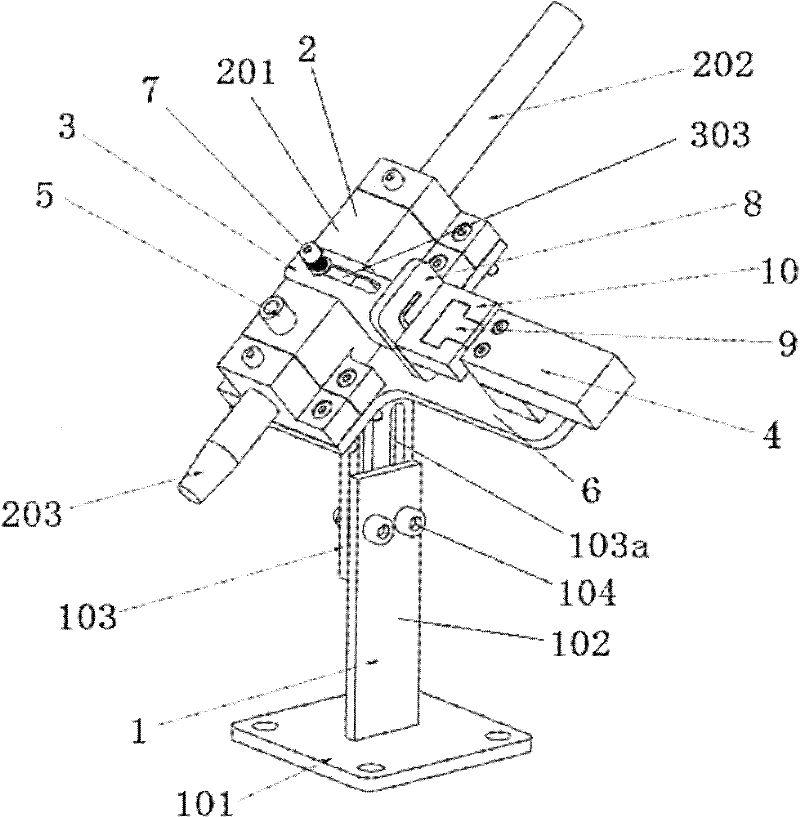

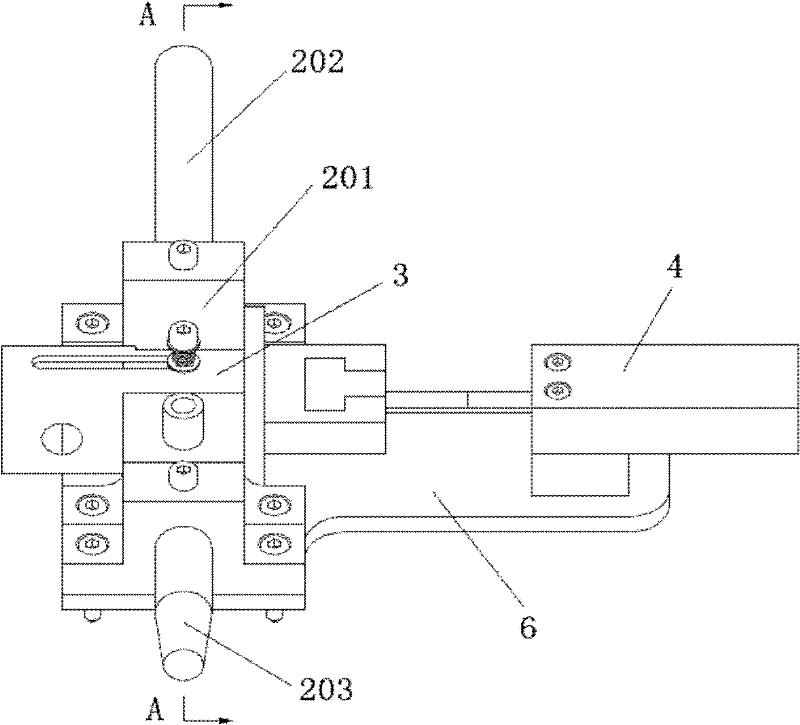

[0028] Example: Combined figure 1 - Image 6 As shown, the circuit breaker screw assembly automatic unloading device provided in this embodiment consists of a support frame 1, a material guide pipe 2, a material retaining device, an air blowing device, a mounting plate 6 and a material retaining member pressing device 7. composed of components.

[0029] In this embodiment, the mounting plate 6 is obliquely fixed on the support frame 1, and the feed pipe 2 includes a feed pipe body 201 and upper and lower feed pipes 202, 203 respectively fixed at both ends of the feed pipe body 201, The inside of the guide tube body 201 is provided with guide passages communicating with the upper and lower guide tubes 202, 203, and the first stop piece 301 and the second stop piece 302 on the stopper 3 are placed horizontally In the material guide channel, the material guide tube body 201 and the driving device 4 are fixed on the mounting plate 6 , and the material guide tube 2 is incli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com