Semiautomatic paying-off device

A pay-off device and semi-automatic technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems that the support frame is easily pulled down, the bending is not straight, the wire scrapes the burrs in the steel pipe, etc. Achieve the effect of stable and reliable connection, reduce rotation resistance, and reduce the difficulty of laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

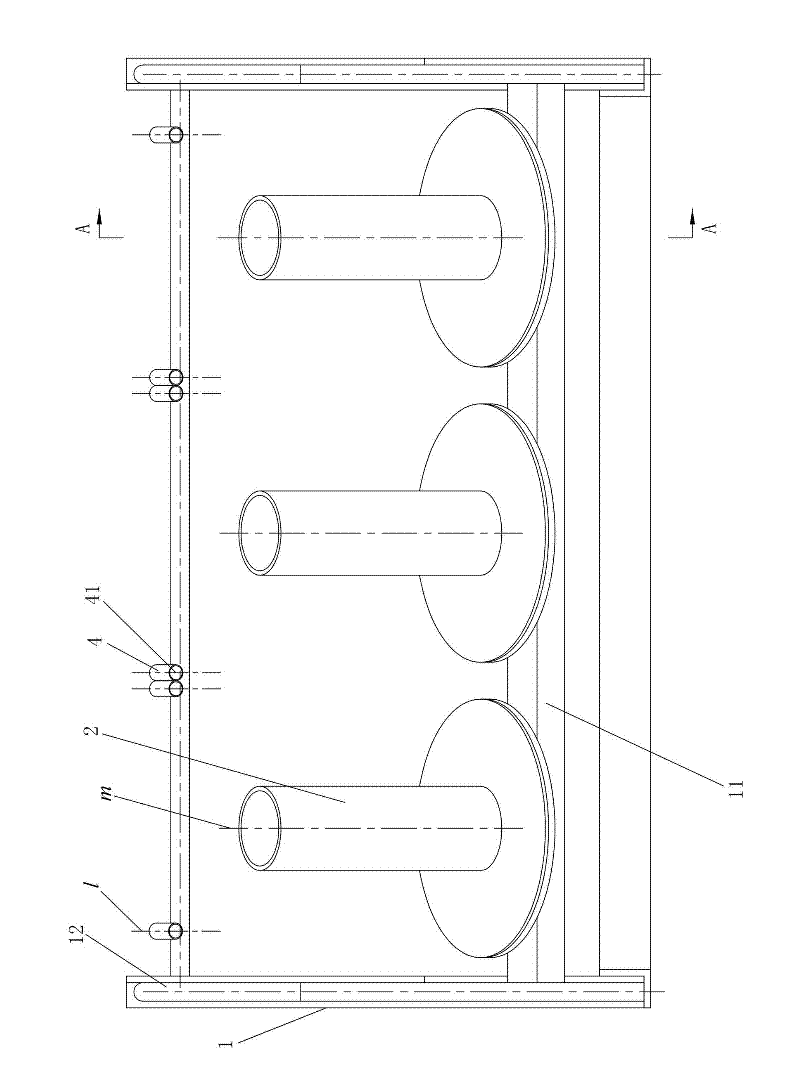

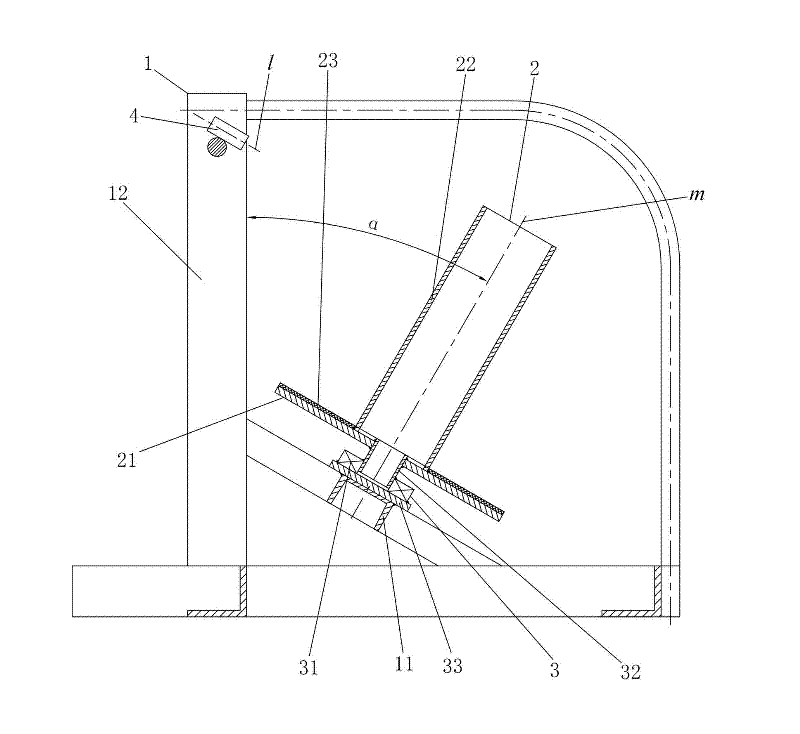

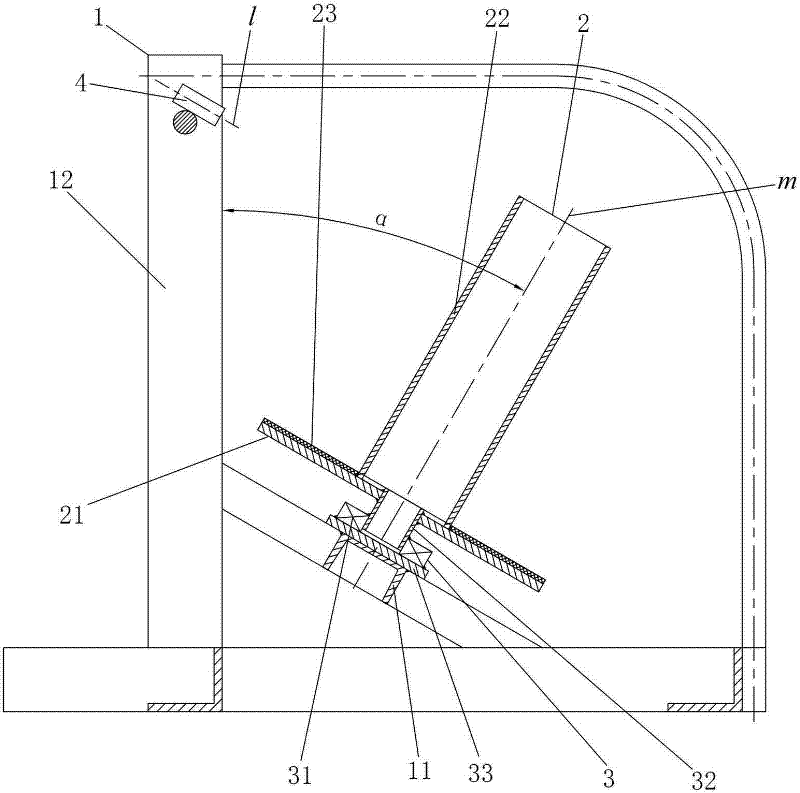

[0020] Such as figure 1 with figure 2 As shown, the semi-automatic pay-off device of the present invention includes a support frame 1 and three pay-off shaft frames 2, each pay-off shaft frame 2 is installed on the support frame 1 by a rotating assembly 3, and the three pay-off shaft frames Axis of rotation of frame 2 m They are arranged obliquely relative to the vertical direction. When the semi-automatic pay-off device is laid, it pulls the pay-off from the top of the pay-off shaft frame 2, which is not easy to be pulled down. It has good stability, and one semi-automatic pay-off device can simultaneously lay three Rolling wires is more efficient. In addition, two or more pay-off spools 2 can be set on the support frame 1 according to actual needs, so as to adapt to different working conditions.

[0021] In this embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com