Process method and equipment for refining, extracting and distilling cyclopentane

A technology of extractive distillation and process method, which is applied in the field of cyclopentane refining extractive distillation process method and its equipment, which can solve the problems of low production performance of extraction equipment, large loss of cyclopentane, and inability to build too high, so as to improve market competitiveness and product added value, increase relative volatility, and ensure flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

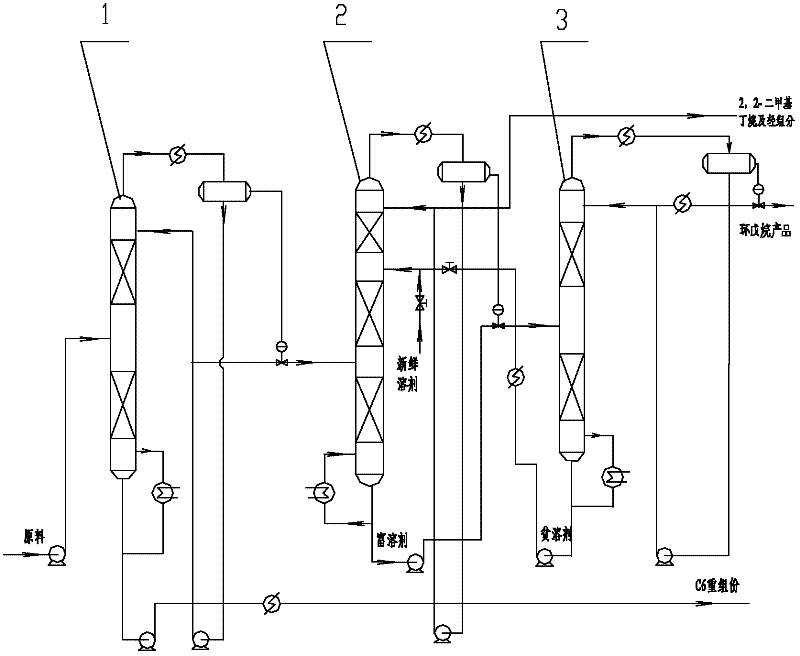

Image

Examples

Embodiment 1

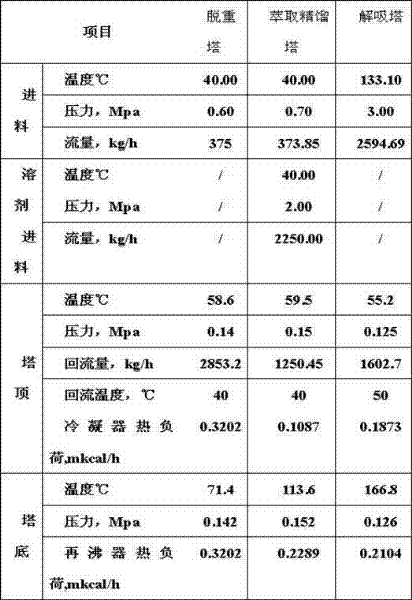

[0036] See Table 2 to Table 6.

[0037]The raw material 40°C crude cyclopentane (Table 1) enters the weight removal tower through the middle part of the feed pump, and after rectification, the gas phase cyclopentane at the top of the weight removal tower at about 58.6°C is condensed and cooled by the top condenser of the weight removal tower to 40°C enters the reflux tank at the top of the weight-removing tower; the liquid phase at 40°C in the reflux tank at the top of the weight-removing tower is pressurized to 0.2mpa by the reflux pump of the weight-removing tower, and then divided into two paths, one is returned to the reflux in the tower, and the other is used as the middle The product is sent to the extractive distillation tower; the liquid phase at the bottom of the de-weighting tower at about 70.3°C is drawn out and then heated to about 71.4°C by the reboiler of the de-weighting tower and then returned to the tower, and the heavy components of the liquid phase at the bot...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap