Printing method and device for inkjet and liquid metal mixed printing and product

A liquid metal and inkjet technology, applied in the directions of copying/marking methods, printing, typewriters, etc., can solve the problem of adding silk screen or marking to liquid metal printed circuits, and achieve flexible screen marking forms, convenient operation, and improved circuit integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

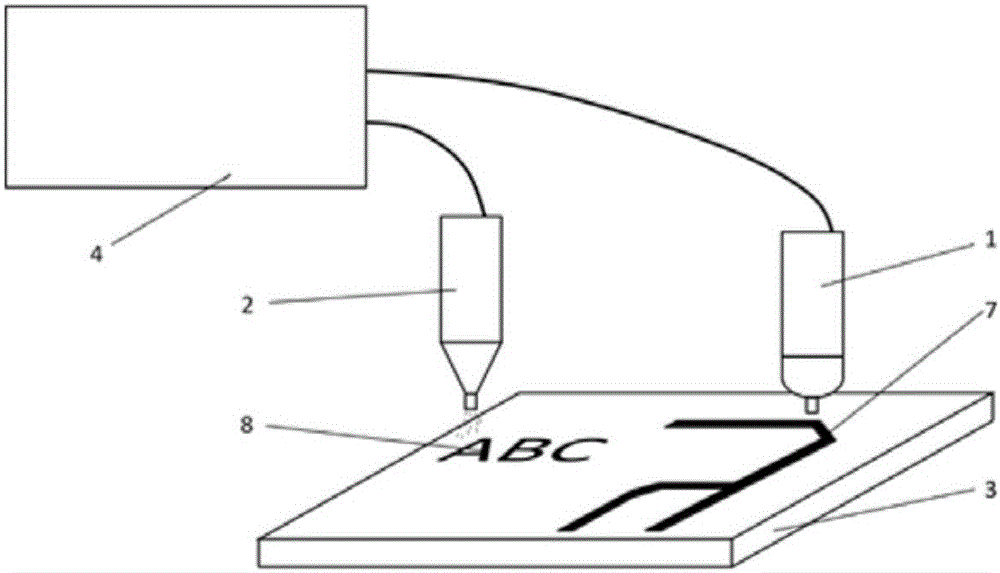

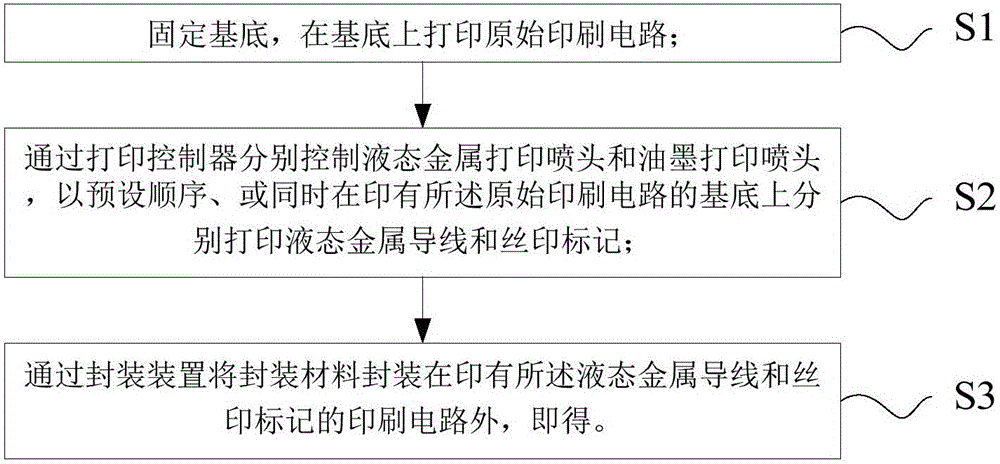

[0046] Such as figure 1 As shown, in the printing method and device for inkjet and liquid metal mixed printing provided in the first embodiment, the liquid metal printing nozzle 1 and the ink printing nozzle 2 are respectively connected to the printing controller 4, and the printing controller 4 can be controlled separately Liquid metal printing nozzle 1 and ink printing nozzle 2 so that liquid metal printing nozzle 1 and ink printing nozzle 2 can print liquid metal wires 7 and silk screen marks 8 on substrate 3 in a preset order or at the same time, so that they can print at one time A printed circuit printed with liquid metal wires 7 and silk screen marks 8 is printed. The printing method is carried out by using the device, and has the characteristics of high integration, convenient operation and flexible form of the silk screen mark 8. The generated product can effectively expand the complexity and applicability of the existing liquid metal printed circuit.

[0047] The device...

Embodiment 2

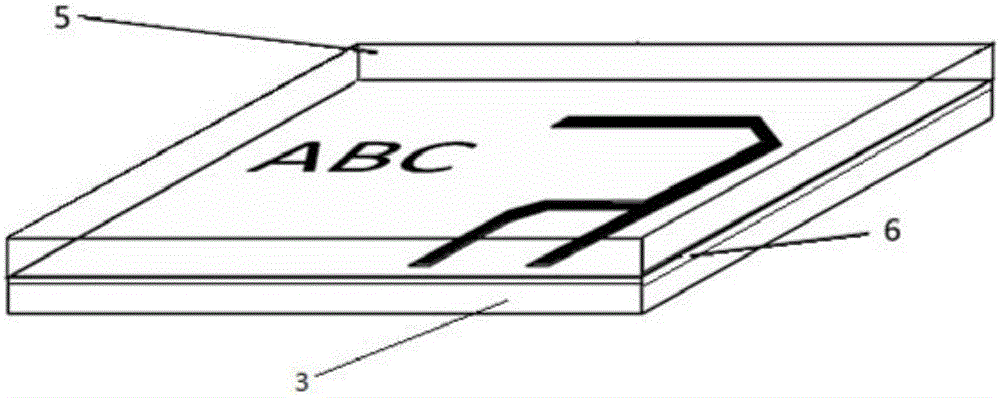

[0060] Such as Figure 5 , Image 6 As shown, the device structure of the second embodiment is basically the same as that of the first embodiment, and the similarities will not be repeated. The difference is: in the device of the second embodiment, the packaging device is connected to the print controller 4 for packaging The material is encapsulated outside the liquid metal wire layer 9 or the silk screen marking layer 10, that is, the packaging device is used to encapsulate the packaging material on the substrate 3 printed with the liquid metal wire 7 or the silk screen mark 8.

[0061] The printing method and products of the second embodiment are basically the same as those of the first embodiment, and the similarities will not be repeated. The difference is: in the printing method of the second embodiment, the liquid metal is controlled by the printing controller 4 in step S2. The printing nozzle 1 and the ink printing nozzle 2 respectively print liquid metal wires 7 and silk s...

Embodiment 3

[0070] Such as Figure 8 As shown, the third embodiment adopts the printing method of the first embodiment or the second embodiment, and the generated product is the same as the first embodiment or the second embodiment. The basic structure of the device of the third embodiment is basically the same as that of the first or second embodiment, except that the liquid metal printing nozzle 1 and the ink printing nozzle 2 of the third embodiment are installed on the same spray gun. When printing the liquid metal wire 7, the liquid metal printing nozzle 1 can be opened through the printing controller 4, and the ink printing nozzle 2 can be closed; when the silk screen mark 8 is printed, the ink printing nozzle 2 can be opened through the printing controller 4 and the liquid Metal printing nozzle 1; when it is necessary to print liquid metal and silk screen marks 8 at the same time, the liquid metal printing nozzle 1 and ink printing nozzle 2 can be opened at the same time.

[0071] It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com