Pressure-balancing flow-balancing honeycomb checker brick

A checker brick and honeycomb technology, which is applied in the field of metallurgical refractory bricks, can solve the problems of strong pulse, uneven air volume, short service life, etc., and achieve the effects of slowing down resistance, increasing heat exchange area, and small impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

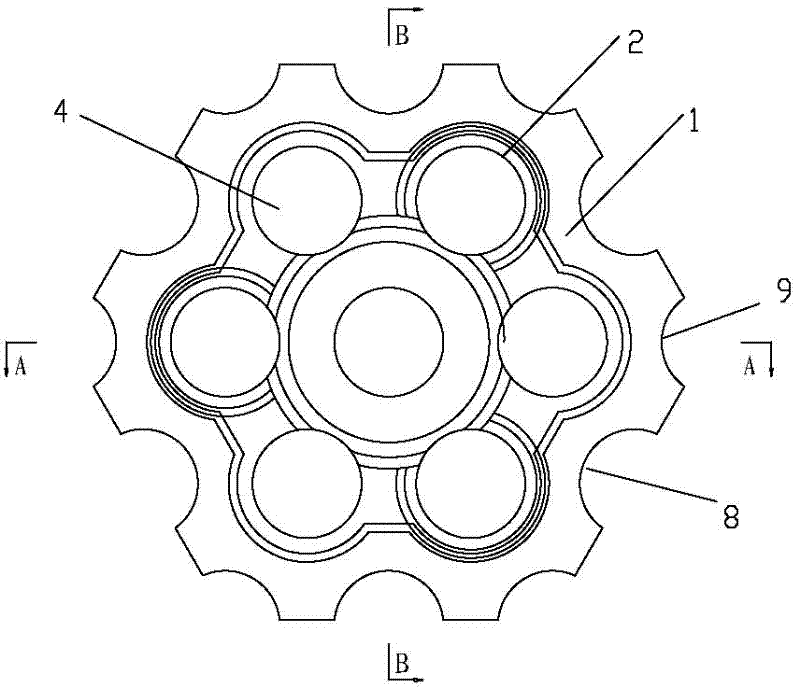

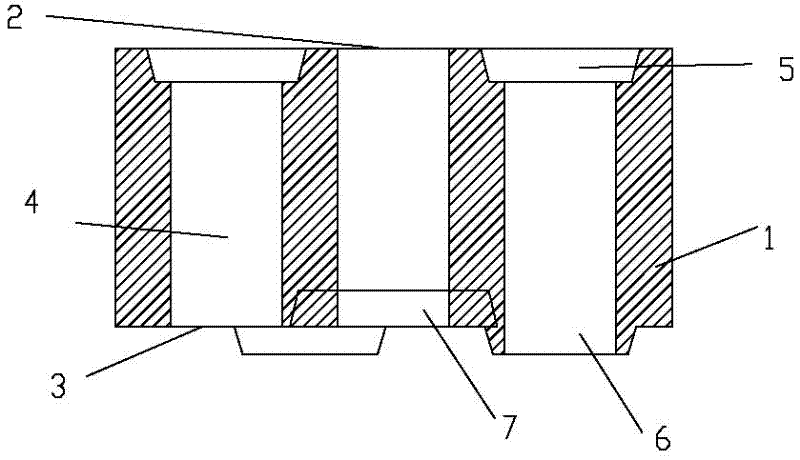

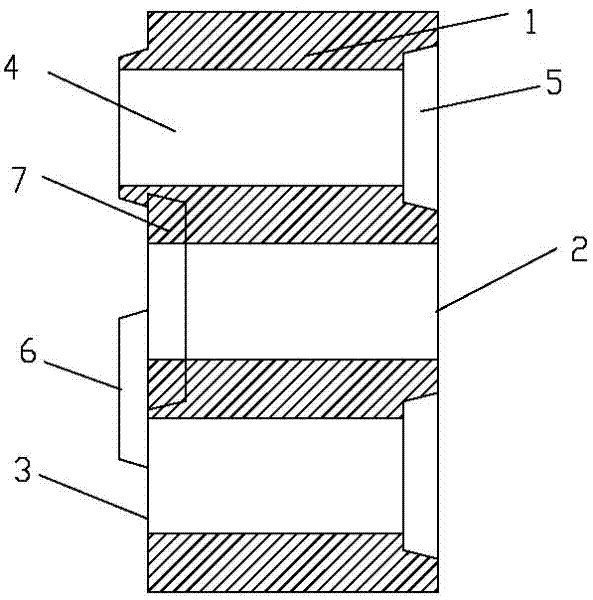

[0016] Depend on Figure 1-9 As shown, the present invention includes a brick body and a through hole. The brick body 1 is a regular hexagonal cylinder, and through holes 4 are evenly distributed in the brick body. The axis of the through hole is perpendicular to the cross section of the brick body, and the upper end 2 of the through hole is smaller than the lower end. 3. The tapered through hole that constitutes the lattice brick. The upper end surface of the brick body has an arc-shaped upper end annular groove 5 centered on the central hole outside the periphery of the central hole, and the upper end annular groove 5 intersects with the cone. There are three bosses 6 evenly distributed on the lower end surface of the brick body, and there is a circular groove 7 centered on the center hole in the middle of the three bosses. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com