Operation method of tunnel maintenance dust-removal trolley in constant temperature and humidity mode

A technology with constant temperature and humidity and operation methods, which is applied in the directions of dust prevention, earth square drilling, safety devices, etc., can solve problems such as high labor intensity, insufficient maintenance, and influence on construction, so as to improve construction efficiency, improve construction quality, and reduce The effect of work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

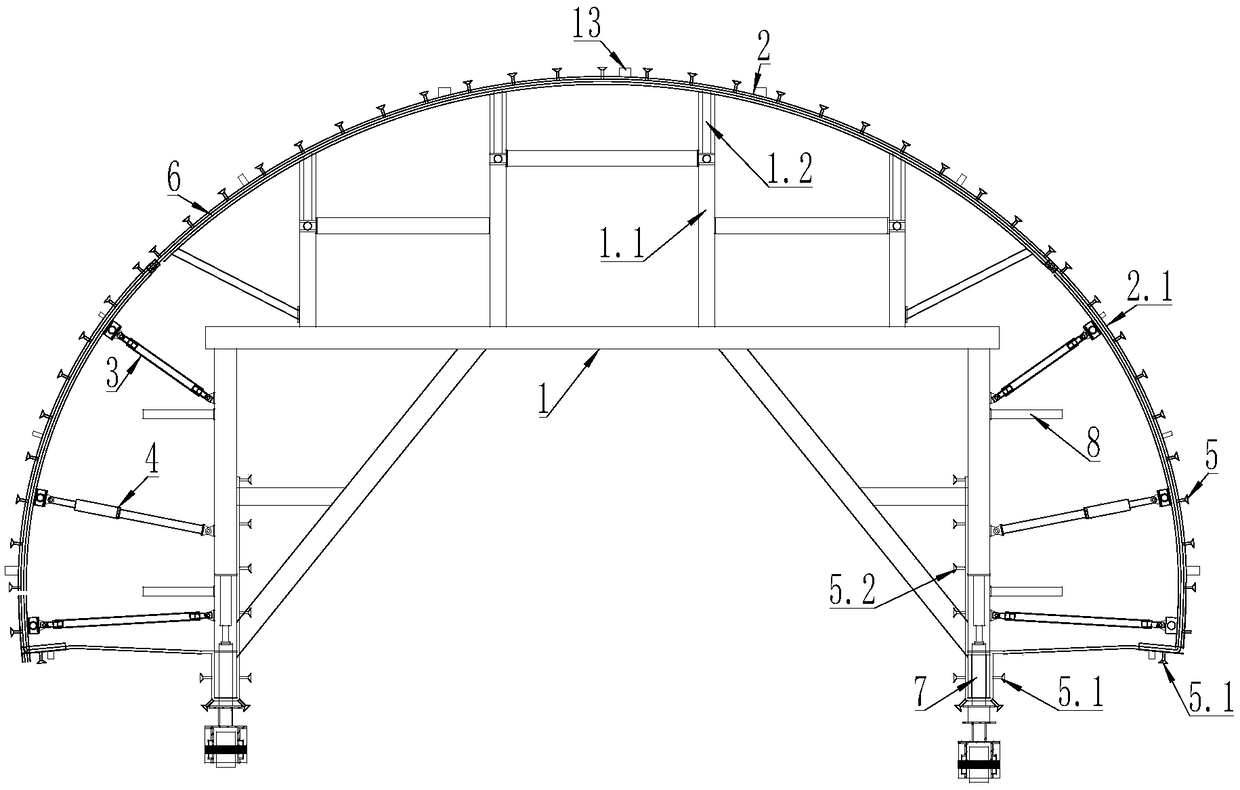

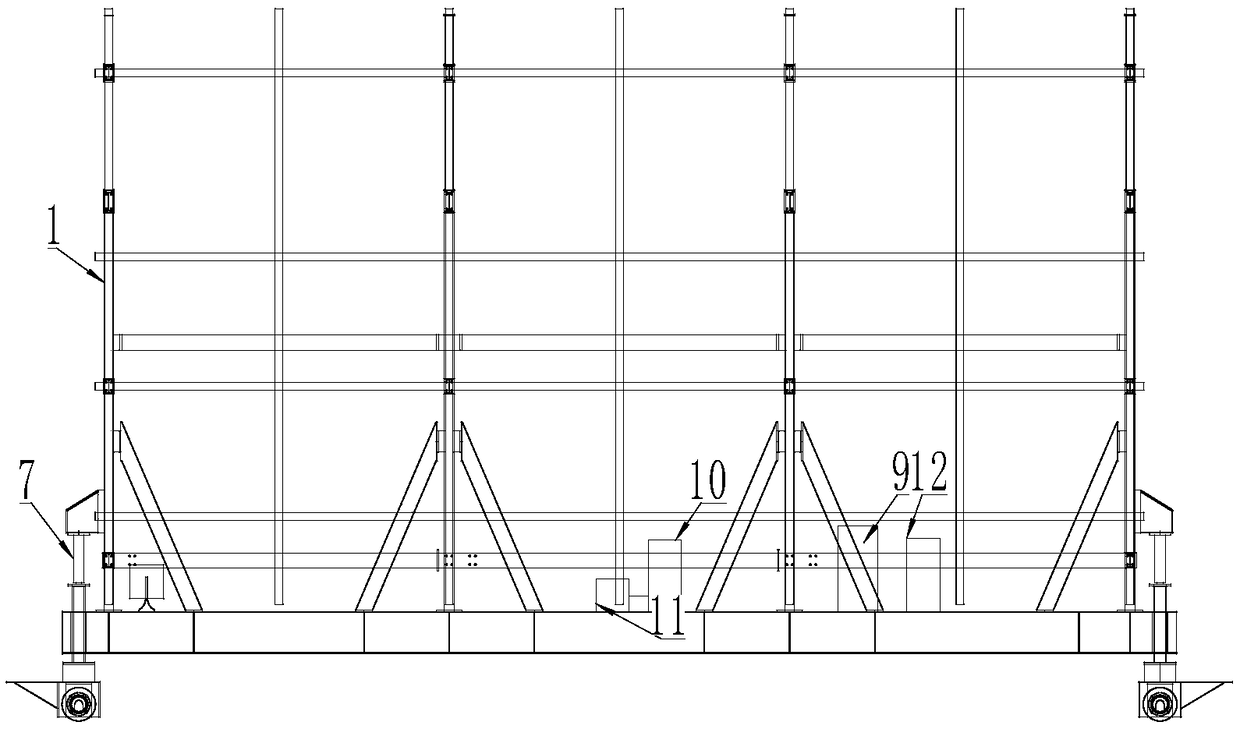

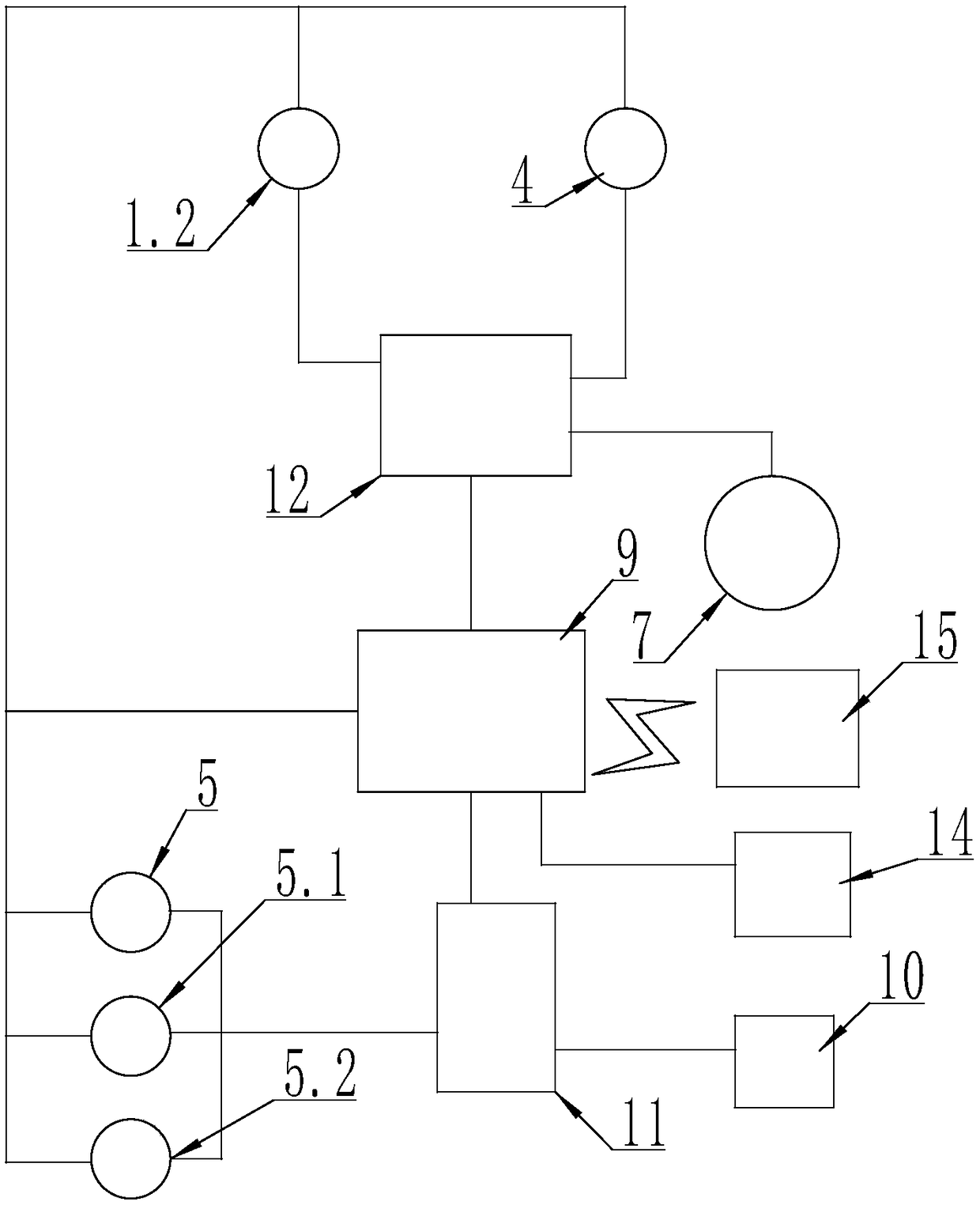

[0019] A top frame 1.1 is arranged on the upper surface of the door frame 1, and a top mold hydraulic cylinder 1.2 is arranged on the upper part of the top frame 1.1, and through beams are arranged between at least three sides of the door frame 1 parallel to each other. The frame 1.1 and the through-beam form a support frame, and one side of the support frame is provided with a temperature-controlled water tank 10, one side of the temperature-controlled water tank 10 is provided with a high-pressure water pump 11, and a pipeline is arranged between the temperature-controlled water tank 10 and the high-pressure water pump 11. A hydraulic pump station 12 is installed on the other side, and a PLC console 9 is installed on one side of the hydraulic pump station 12. A handheld terminal 14 is installed on the PLC console 9, and a wireless terminal 15 is installed on the PLC console 9. Between the PLC console 9 and the wireless terminal 15 Wireless connection, two pairs of platforms 8...

Embodiment 2

[0024] The upgrading mechanisms of the top mold hydraulic cylinder 1.2, the side mold hydraulic cylinder 4, and the lifting traveling mechanism 7 all adopt servo hydraulic cylinders.

Embodiment 3

[0026] The wireless terminal 15 is a notebook computer or a mobile phone, one of them or a combination of more than one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com