Full-automatic measuring method of chemical reaction between carbon dioxide and coal or coke

A carbon dioxide and measurement method technology, applied in the direction of analysis materials, instruments, etc., can solve the problems of misleading production, cumbersome process, low precision, etc., and achieve the effect of fast response, high measurement accuracy and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

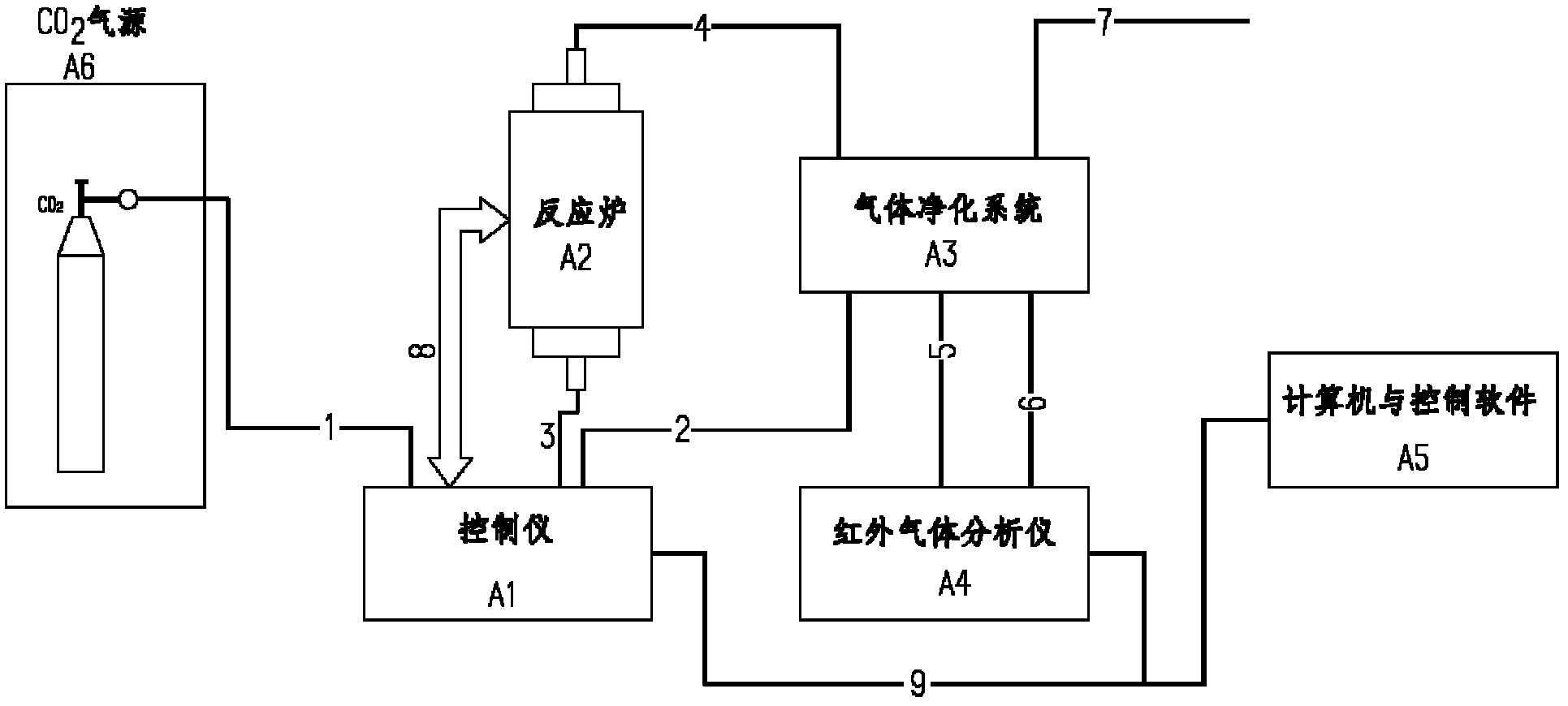

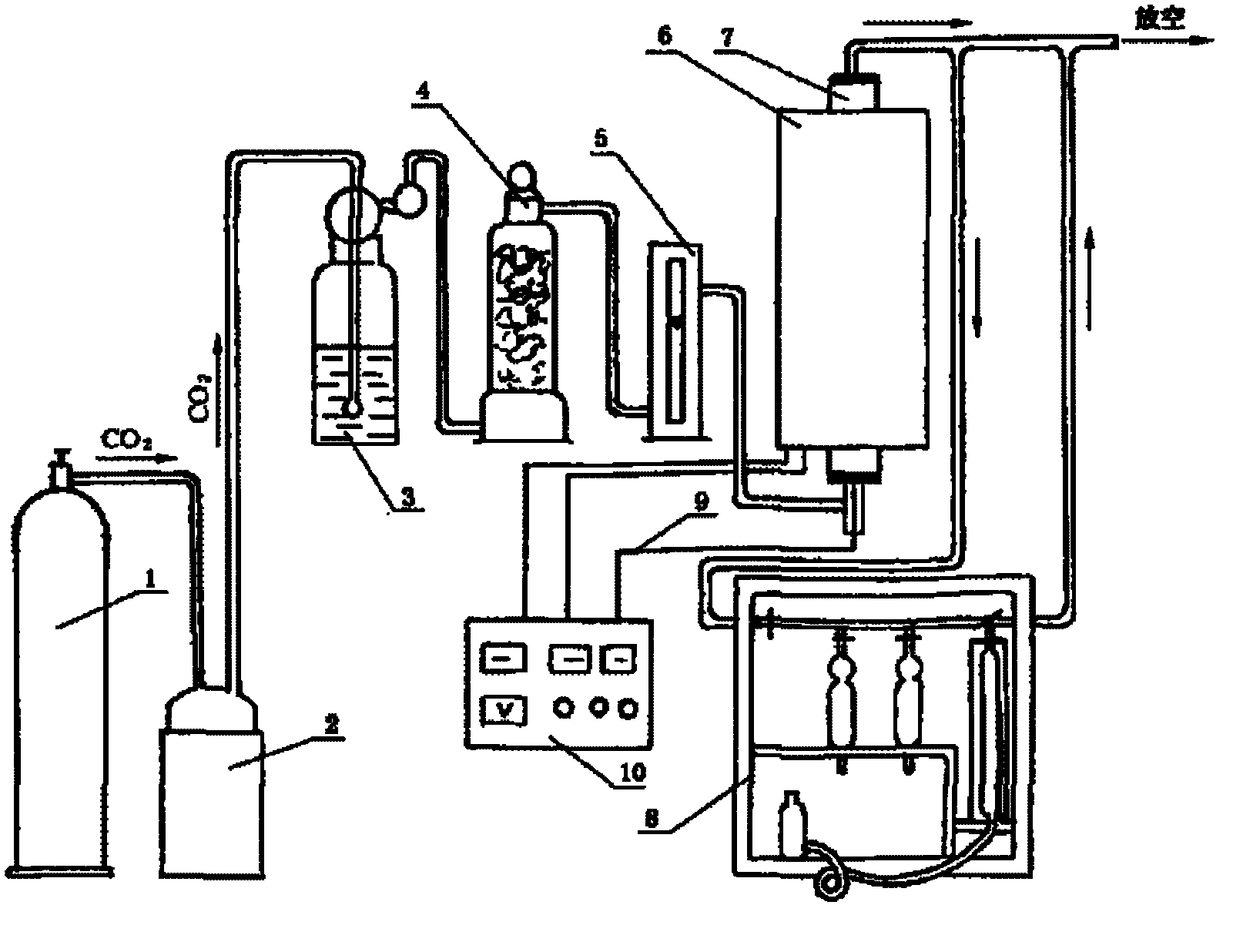

[0048] See figure 1 , Fully automatic coal, coke to carbon dioxide chemical reaction measuring device, including controller A1, reaction furnace A2, gas purification system A3, infrared gas analyzer A4, computer and control software A5, gas source device A6.

[0049] The controller A1 is respectively connected with the reaction furnace A2, the gas source device A6, and the gas purification system A3. The functions of the controller include: 1) realizing the automatic control of the temperature of the reaction furnace A2; 2) realizing the control before and after the reaction Flow detection and flow control of carbon dioxide gas, and gas switching and switch control before and after the reaction. The controller A1 can also be composed of an embedded PC, so that the control software A5 can be installed in the embedded PC, making the system more simplified and convenient.

[0050] The reaction furnace A2 is respectively connected with the controller A1 and the gas purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com