A granularity analysis test device simulating tailing dam hydraulic sorting and an application method thereof

A technology of hydraulic separation and test device, applied in particle size analysis, particle and sedimentation analysis, measuring device, etc., can solve problems such as large deformation of the connection between the slurry pipe and the telescopic rod, blockage of the slurry pipe, affecting normal slurry discharge, etc. , to achieve the effect of convenient and quick deposition motion law, accurate test results and realistic accumulation state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

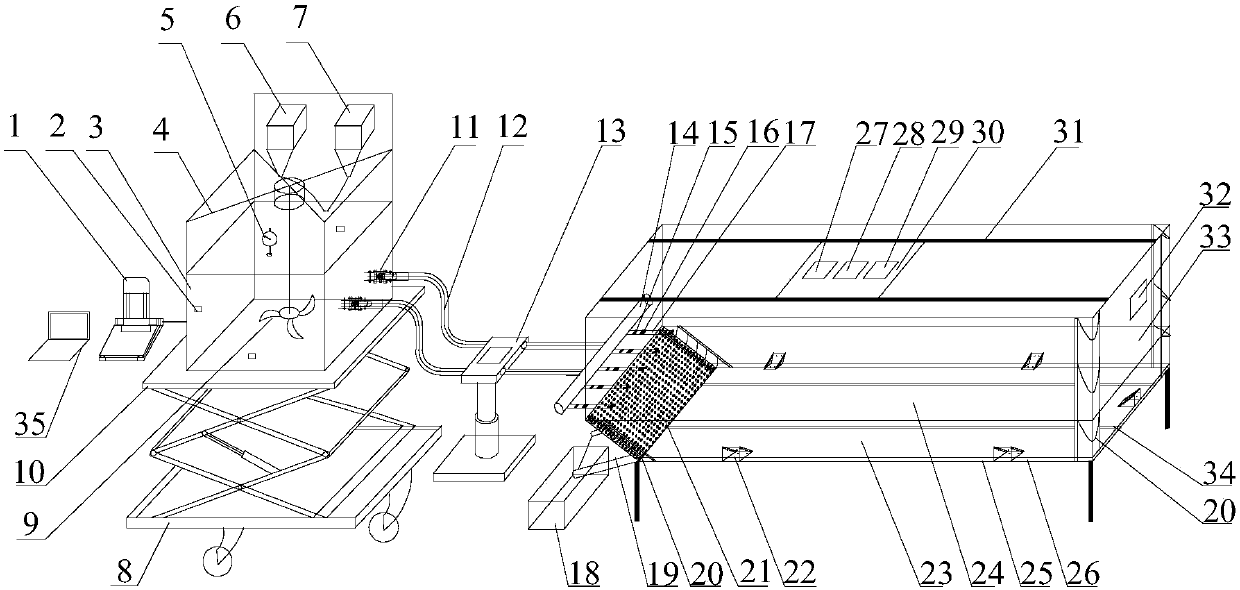

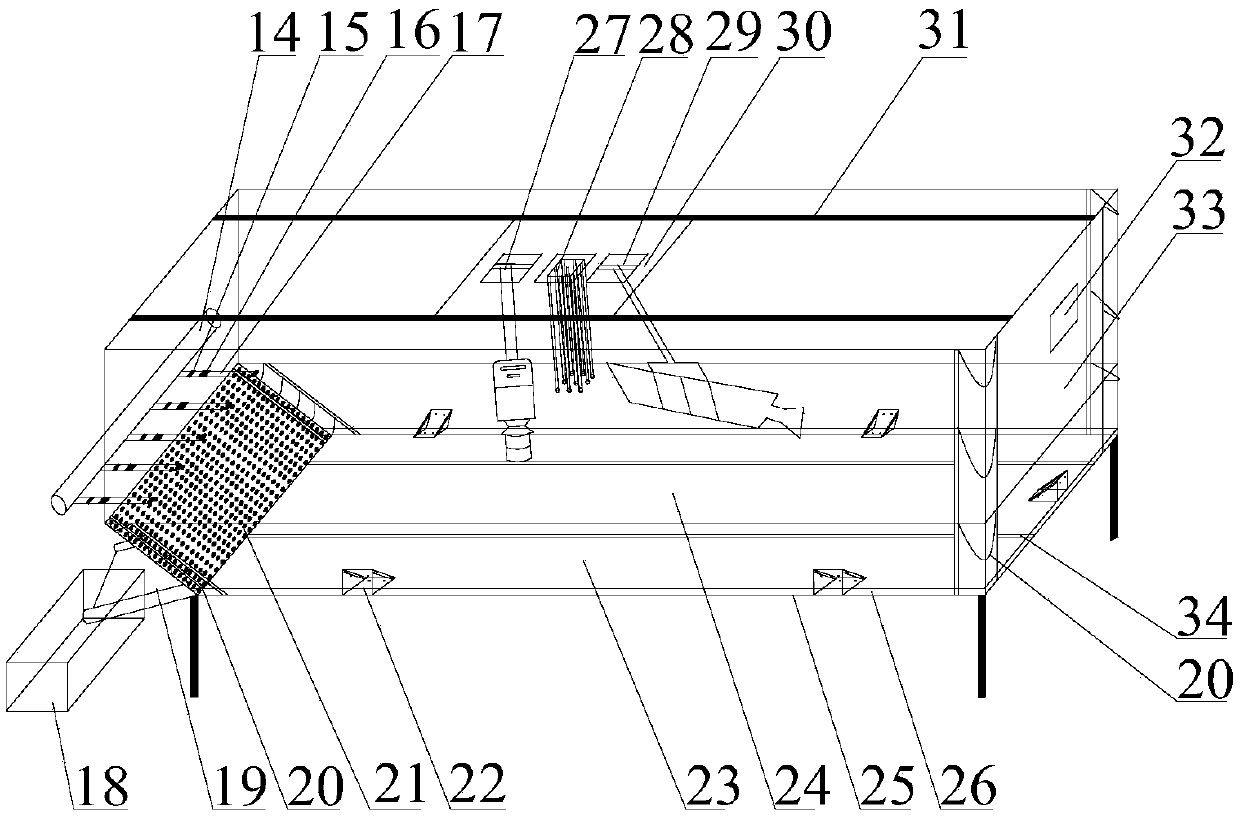

[0047] combine figure 1 , This embodiment simulates the particle size analysis test device for tailings dam hydraulic separation, including a stirring device, a slurry adjustment device and a simulation device.

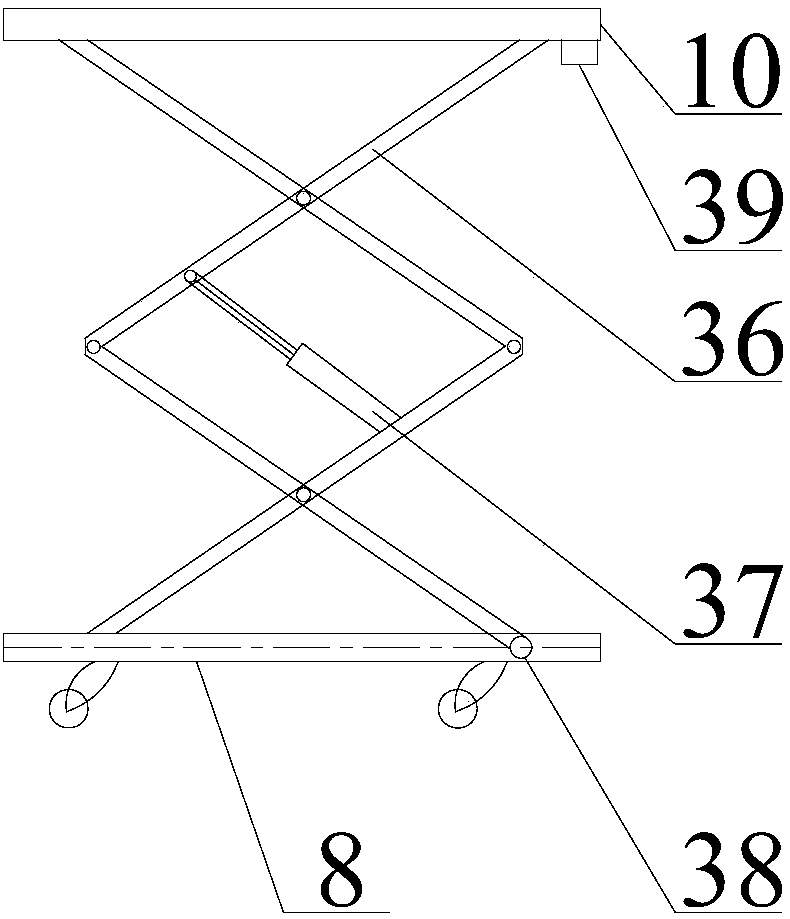

[0048] Described stirring device comprises stirring box 3, and stirring box is a sealed structure, and stirring box is connected with booster pump 1, and pressure gauge 5 is installed on the stirring box; Agitator 9 is installed in the stirring box by agitator bracket 4, and stirring box A sand bin 6 and a water bin 7 are fixedly installed on the upwardly extending rear wall, and a sand concentration measuring instrument 2 is respectively installed on the side wall and the bottom of the mixing box; there is a lifting device for the mixing box at the bottom of the mixing box. figure 2 Shown, comprise the telescopic support that is made of scis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com