Ship rotary crane jib laying automatic control method and control device

An automatic control device and crane technology, which is applied in the direction of cranes, transportation and packaging, load hanging components, etc., can solve the problems of inability to accurately control the pre-tightening tension value of the luffing wire rope, inaccurate control of the operation of the boom, and complicated operation processes, etc. , to achieve the effect of simplifying the operation process of preloading and shelving, improving the safety of operation and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

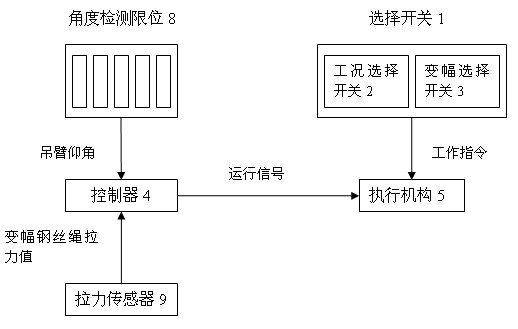

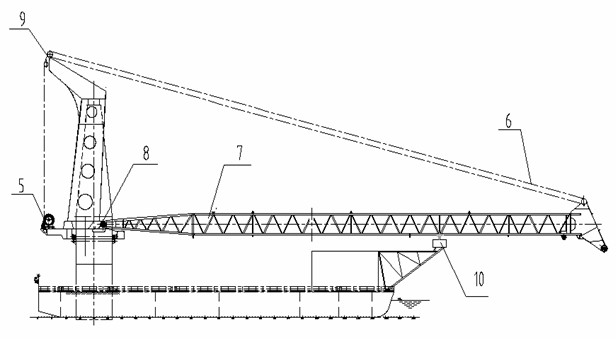

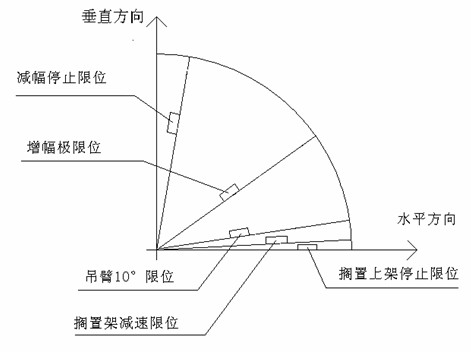

[0045] see figure 1 , The principle diagram of the automatic control method for the arm of the marine slewing crane of the present invention, the automatic control device is composed of a selector switch 1, an angle detection limit 8, a controller 4 and an actuator 5. Among them, the selector switch 1 is connected with the actuator 5 for sending work instructions to the actuator 5, and the angle detection limit 8 is connected with the input end of the controller 4 for measuring the elevation angle data of the boom 7 and inputting it to the controller 4 , the input end of the controller 4 is connected to the angle detection limit 8, and the output end is connected to the actuator 5, which is used to receive measurement data and determine the boom speed according to the preset program, and send a running signal to the actuator 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com