Full-automatic grinding wheel demoulding machine

A stripping machine, fully automatic technology, used in metal processing equipment, grinding devices, grinding/polishing equipment, etc., can solve the problems of lack of continuity, prone to defective products, unstable product quality, etc., and achieve better functions. The effect of integration, improving the degree of automation, and more humanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

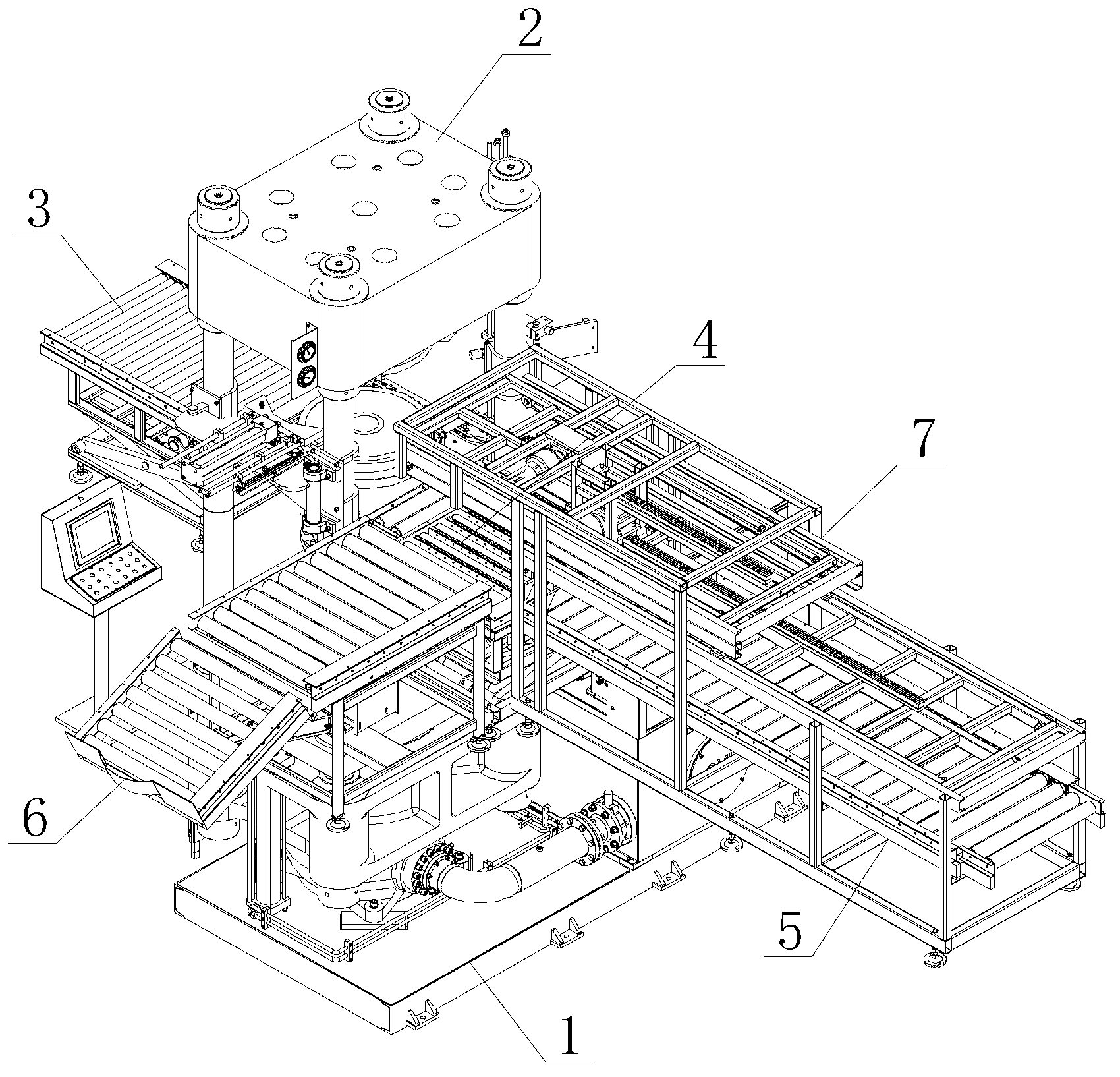

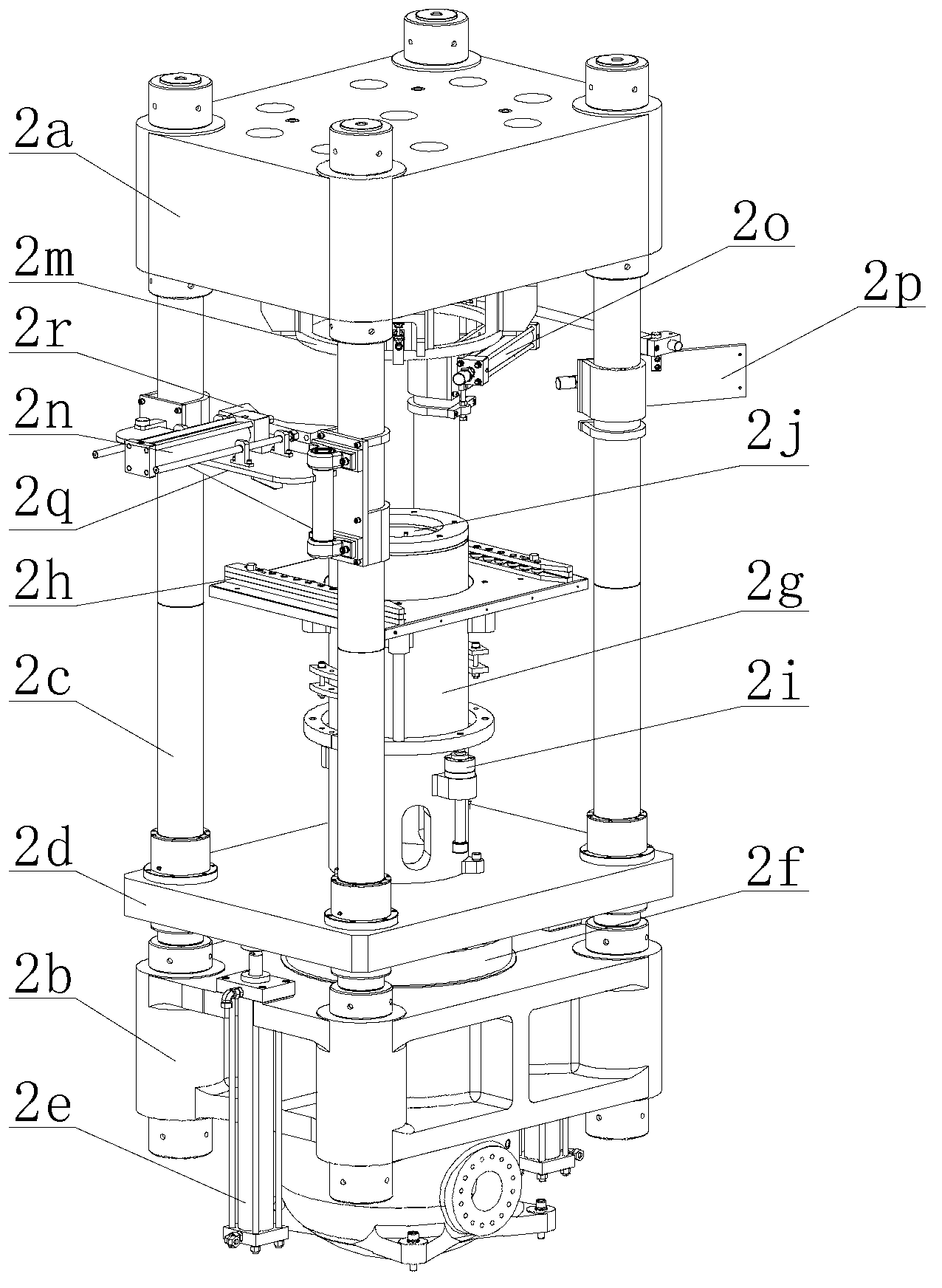

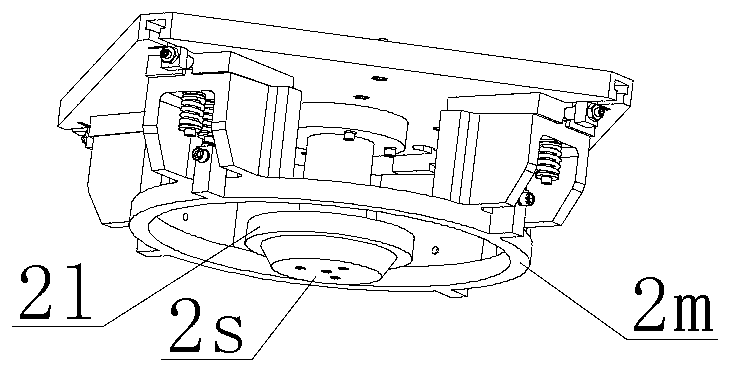

[0028] refer to Figure 1 to Figure 11 As shown, a kind of fully automatic grinding wheel demoulding machine of the present invention comprises frame 1, is provided with demoulding host 2 on frame 1, and described demoulding host 2 sides are respectively provided with mold output mechanism 3 and lifting type The mold material transfer mechanism 4, the side of the lifting type mold material transfer mechanism 4 is respectively provided with a feeding mechanism 5 and a grinding wheel output mechanism 6, and a double-layer push rod mechanism 7 is arranged above the feeding mechanism 5; When the push rod mechanism 7 is pushed out, the un-demoulding grinding wheel can be transported to the center of the demoulding host 2 or the mold after demoulding can be pushed to the mold output mechanism 3 for output; when the double-layer push rod mechanism 7 is retracted, the demoulding The grinding wheel behind the mold is pulled to the mold material transfer mechanism 4, and is delivered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com