Power battery liquid-injection sealing machine

A power battery and sealing machine technology, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of battery safety performance impact, high labor intensity, and loss of manpower and material resources, so as to save complicated operations and reduce labor intensity , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment the present invention is further described:

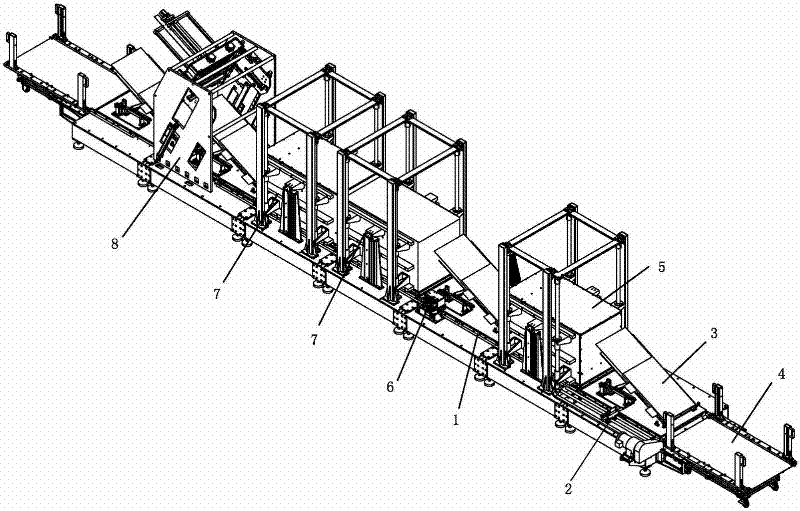

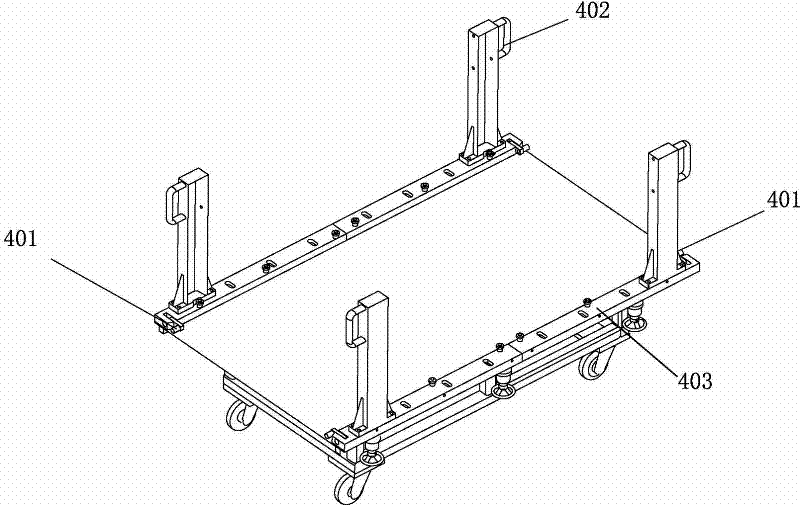

[0028] refer to figure 1 , the power battery liquid injection sealing machine according to the present invention includes a pre-vacuum mechanism 5 before liquid injection, a vacuum static mechanism 7 after liquid injection and a pre-packaging mechanism 8 arranged in sequence, and also includes a carrier trolley mechanism 3 and a transfer trolley mechanism 4. At the same time, the guide rail mechanism 1 listed on both sides of the pre-vacuumizing mechanism 5 before liquid injection, the vacuum static mechanism 7 after liquid injection, and the pre-packaging mechanism 8, and the carrier trolley mechanism 3 is mounted above the transfer trolley mechanism 4 The transfer trolley mechanism 4 is engaged with the guide rail mechanism 1, and a main drive mechanism 2 is included on the outside of the guide rail mechanism 1 and between the pre-vacuumizing mechanism 5 before liquid injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com