Plate heat exchanger

A technology of plate heat exchangers and heat exchange elements, which is applied in the direction of heat exchange equipment, heat exchanger types, heat exchanger shells, etc., and can solve the problems of reducing fluid fluidity and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

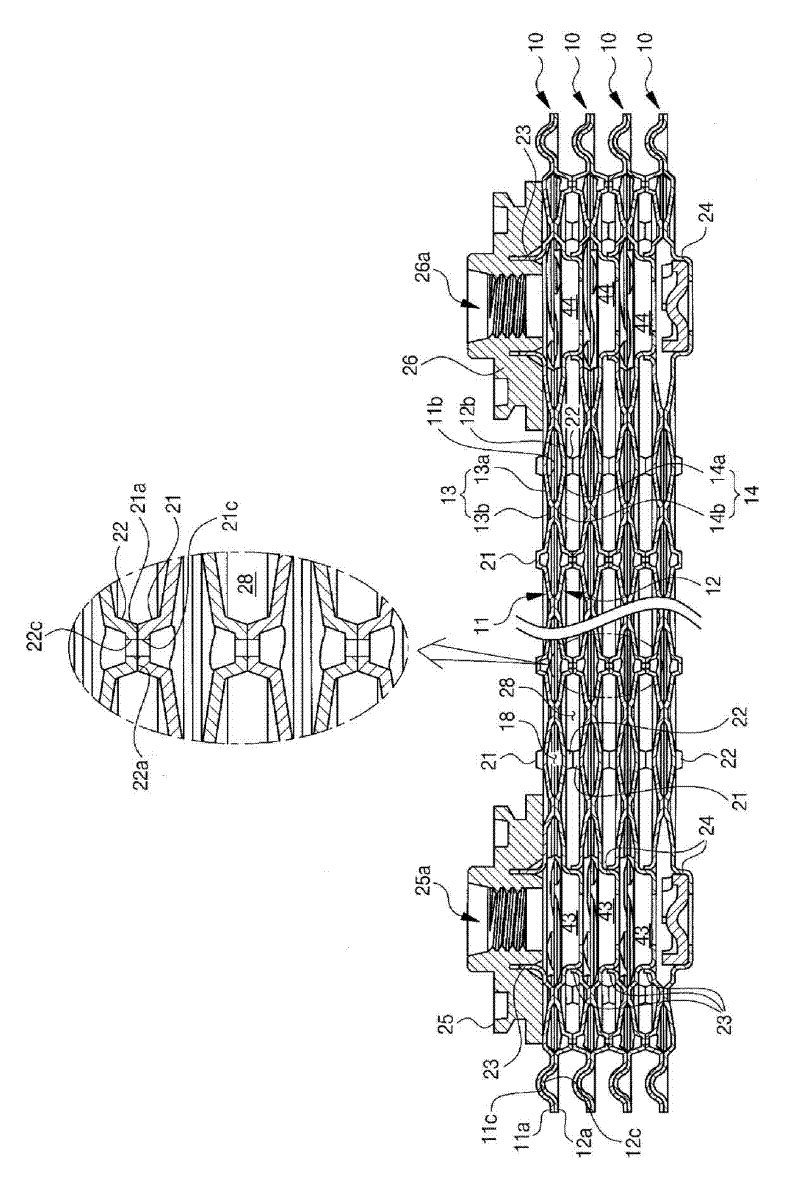

[0025] Figure 1 to Figure 7 A plate heat exchanger according to one embodiment of the present invention is shown.

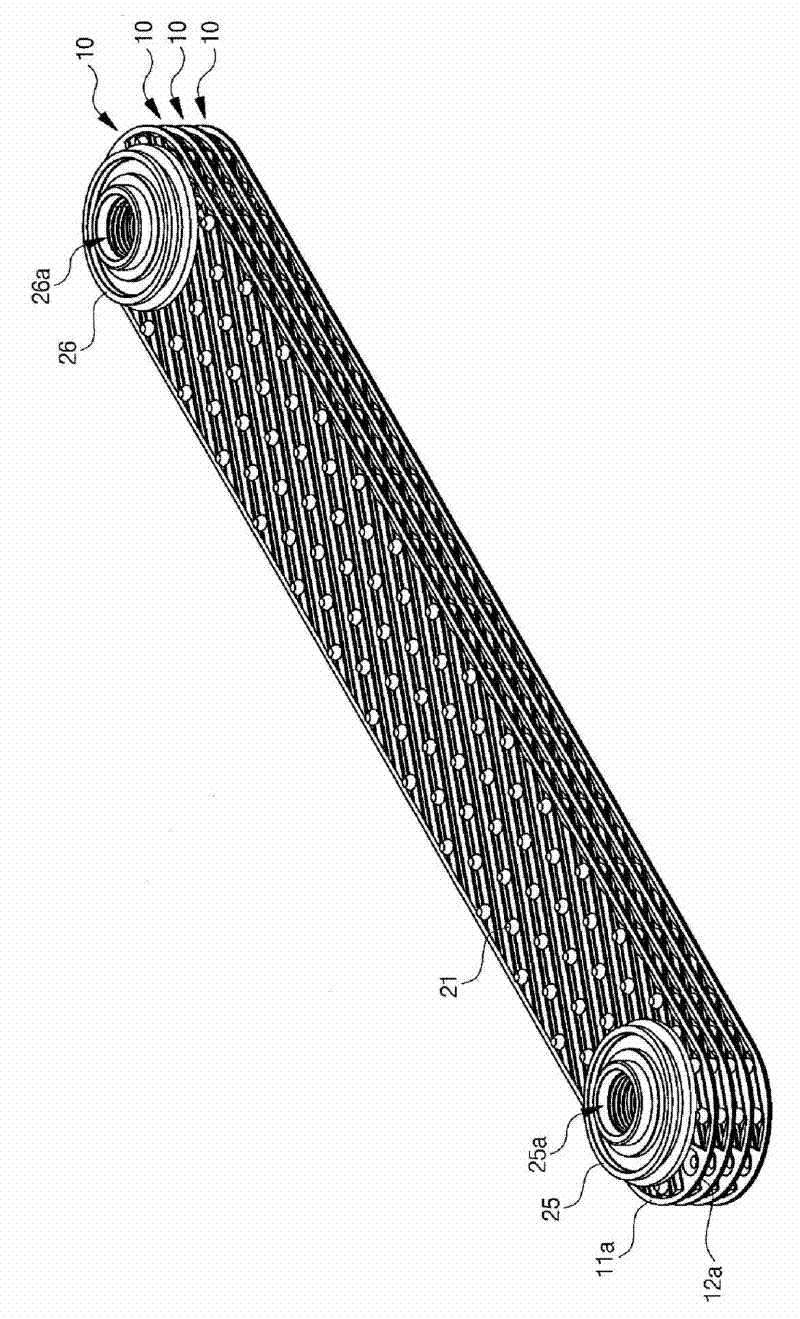

[0026] Such as figure 1 As shown, the plate heat exchanger of the present invention includes a plurality of heat exchange elements 10 (heat exchange elements), and the plurality of heat exchange elements 10 are stacked up and down.

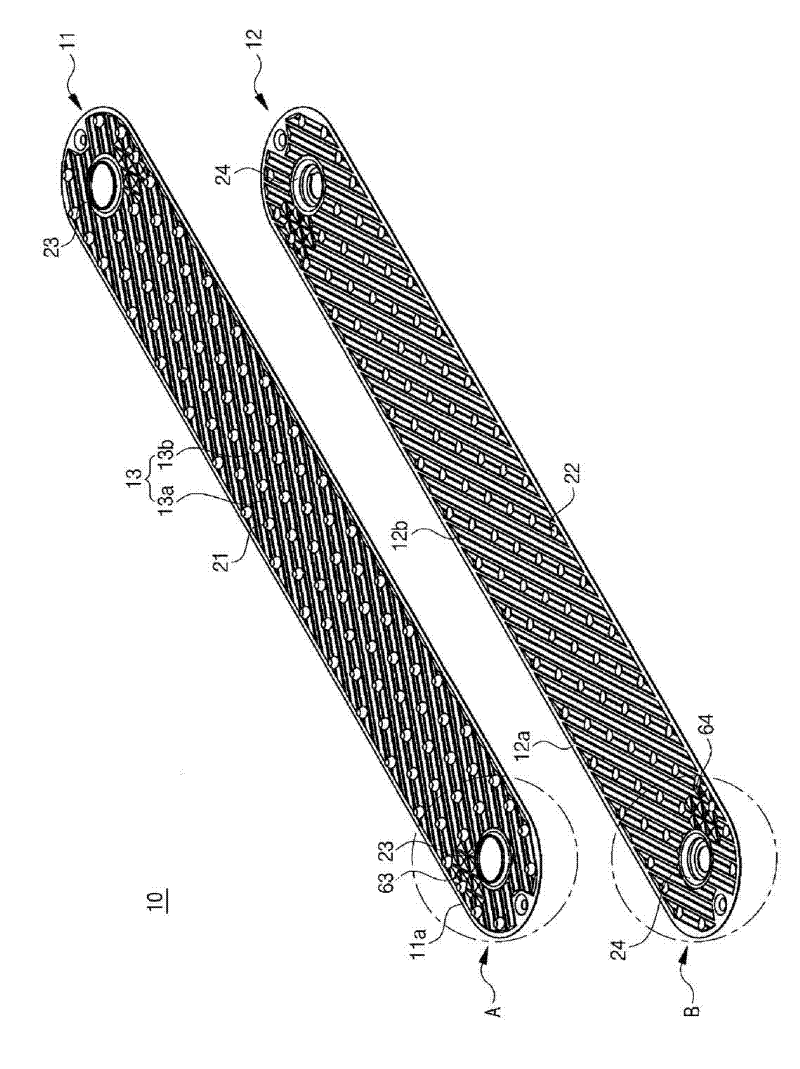

[0027] Such as figure 2 As shown, each heat exchange element 10 is equipped with a first flow channel 18 through which a first fluid such as oil or refrigerant passes. Each heat exchange element 10 is formed by combining an upper plate 11 and a lower plate 12 . The upper plate 11 and the lower plate 12 are made of a metal material with excellent thermal conductivity such as aluminum, and the edges 11a, 12a of the upper plate and the lower plate 11, 12 can be bonded to each other by brazing or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com