Slotted impingement plates for heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

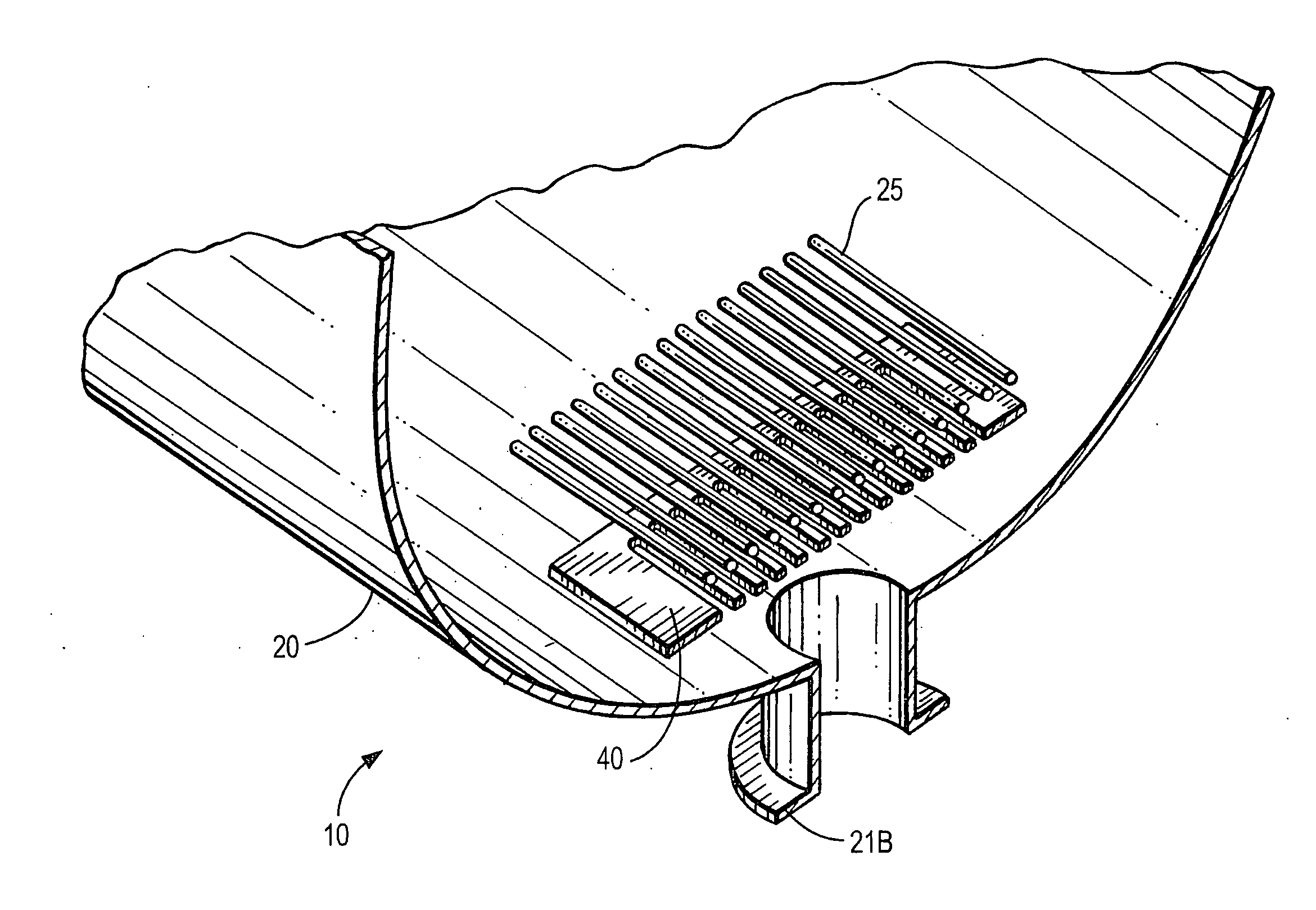

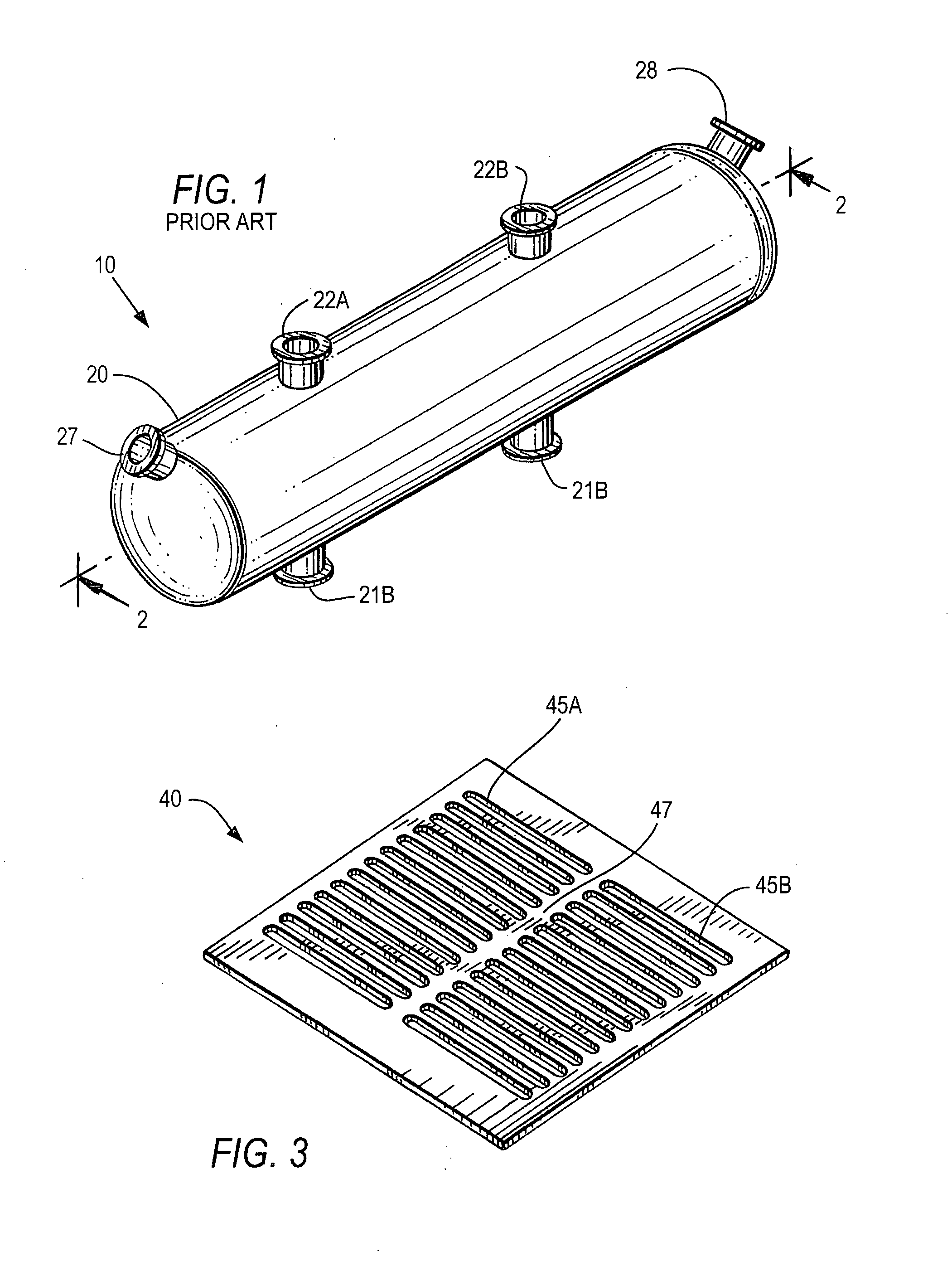

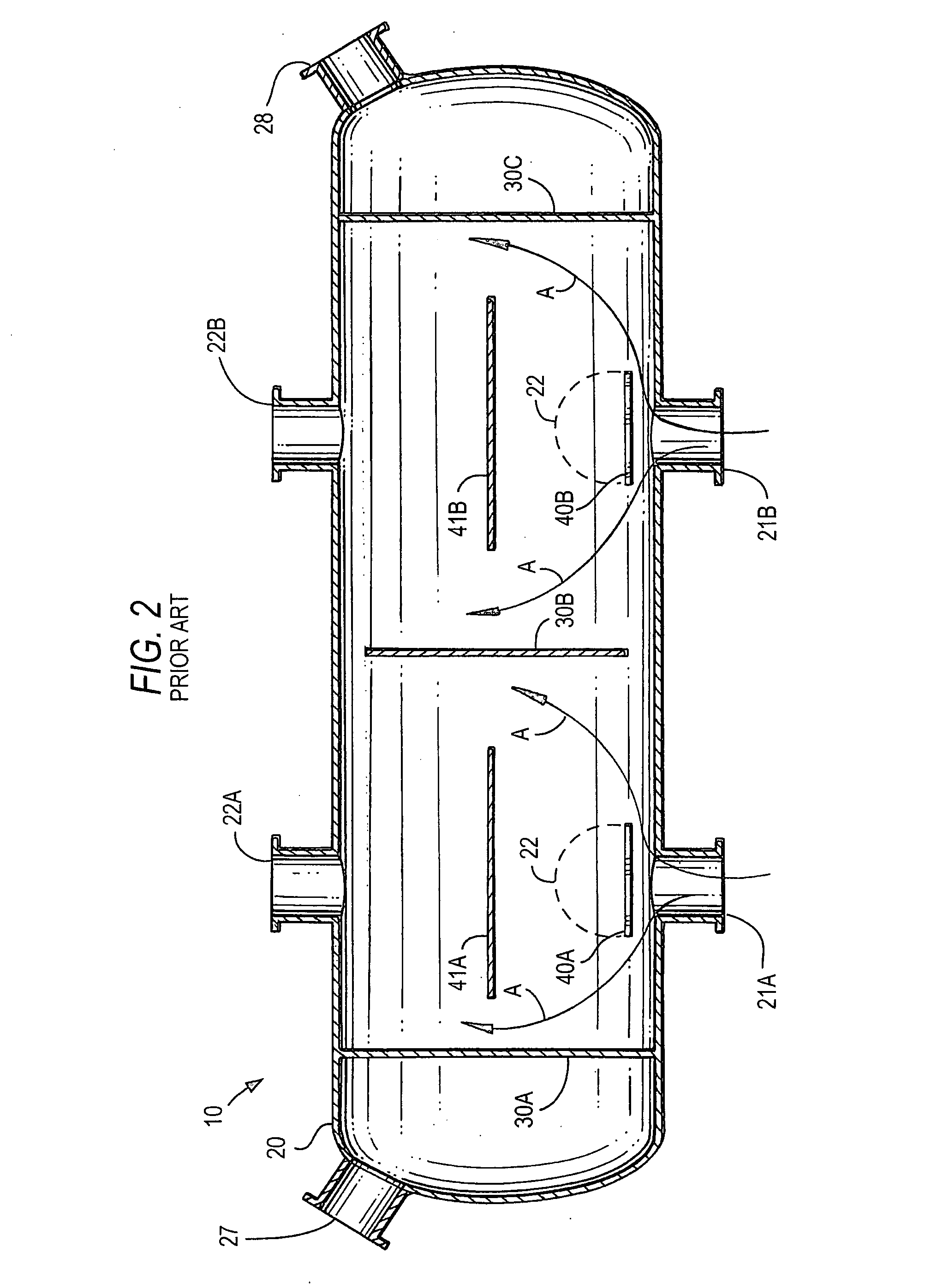

[0015]A preferred embodiment of the impingement plate of the invention is illustrated in FIGS. 3-4. For simplicity and clarity, the heat exchanger 10 in FIG. 4 will be shown as having the same housing or shell 20 as in FIGS. 1-2 and also having the same inlets 21A, 21B, outlets 22A, 22B and bundle of tubes 25. As mentioned above, in the present embodiments it is understood that flowing in these tubes 25 is a relatively hot fluid, with heat transfer from the outer surfaces of these tubes 25 to the relatively cooler second fluid flowing from inlets 21A, 21B through the shell housing to outlets 22A, 22B.

[0016]FIGS. 3-4 illustrate in the heat exchanger housing 20, the impingement plate 40 which is generally planar. Although the impingement plate 40 is shown as being rectilinear, other shapes can be used. The impingement plate 40 includes a plurality of openings 45A, 45B through which a portion of the shell-side fluid passes before contacting the tubes. The openings are preferably in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com