Grain loss monitoring sensor with array buoyant raft structure

A technology for monitoring sensors and grains, applied in cutters, agricultural machinery and implements, applications, etc., can solve the problems of increased measurement error, imperfect overall technology, weak impact signal, etc., to eliminate interference, improve work efficiency, improve The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

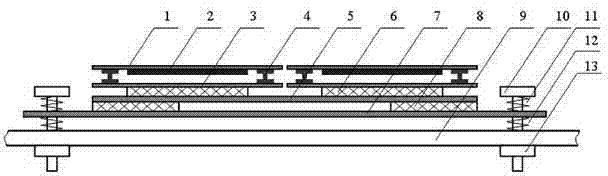

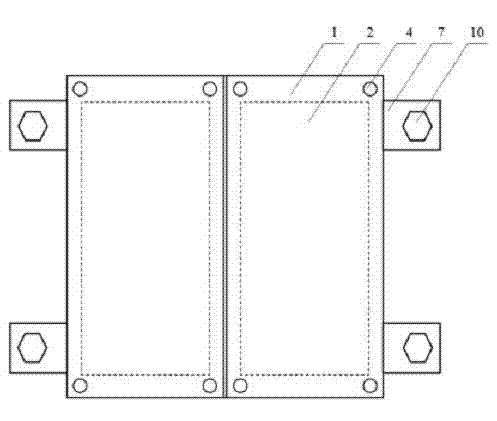

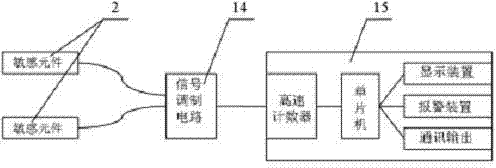

[0023] Combine figure 1 , 2 , The upper panel 1 and the lower panel 3 are fixed by rivets 4, the sensitive element 2 is pasted on the center of the back of the upper panel 1, the damping sheet 6 is installed between the lower panel 3 and the floating support plate 5, and the floating support plate 5 passes The second damping sheet 8 is connected to the base 7, and the base 7 is connected to the bracket 9 through a bolt 10 and a nut 13. A spring 11 is installed between the base 7 and the bolt 10, and a spring 2 12 is installed between the base 7 and the bracket 9.

[0024] The upper panel 1, the sensitive element 2, the lower panel 3 and the rivets 4 together constitute a monitoring unit, and multiple monitoring units are arranged in parallel on the floating support plate 5. The number of monitoring units can be 1-5.

[0025] The upper panel 1 and the lower panel 3 are rectangular with the same shape, the length and width are 100-300 mm, the upper panel 1 and the lower panel 3 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com