Food Processor with High Efficiency Defoamer

A technology of a food processor and a defoaming device, which is applied to beverage preparation devices, household appliances, applications, etc., can solve the problems of reducing heating power, prolonging the production time of soymilk, and slowing the temperature rise of soymilk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

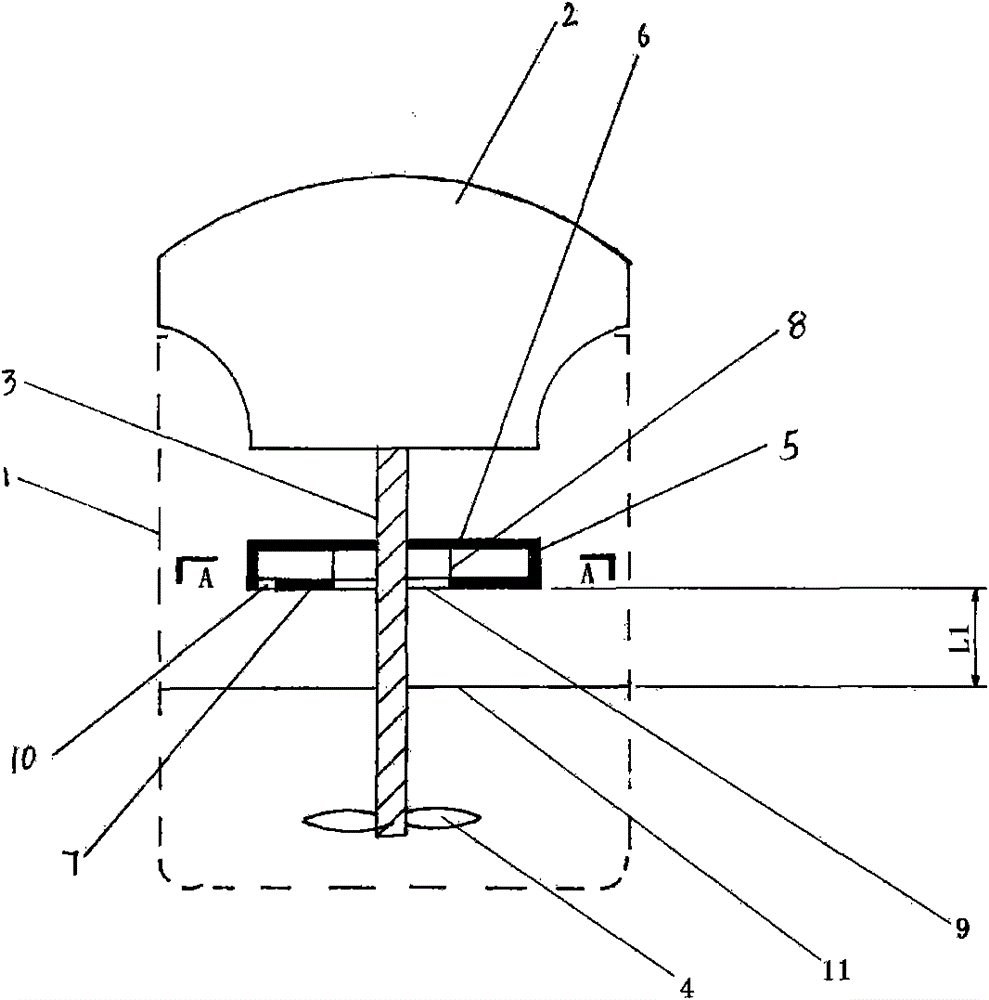

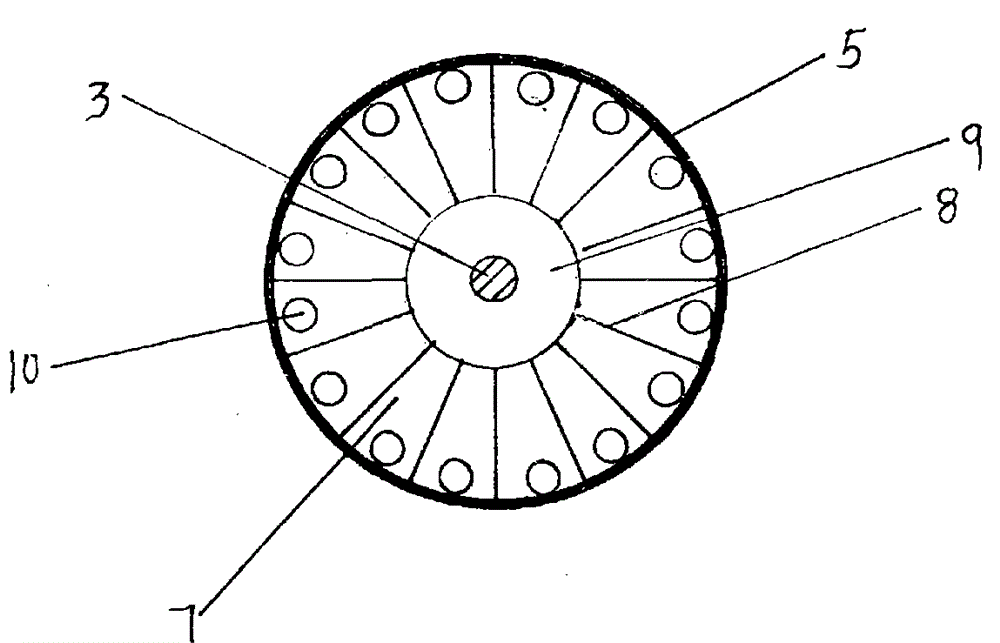

[0098] In the first embodiment, the high-efficiency defoamer 5 is arranged on the crushing knife shaft 3, and its defoaming speed is about 10000 rpm.

[0099]In the first embodiment, due to the optimal design of the position height, rotation radius and rotational speed of the defoaming device from the liquid surface of the food material, it can be realized: no matter what the cause of the foam is, no matter when it is generated, no matter what temperature it is generated, No matter how much the heating power is, as long as the crushing knife shaft 3 is rotating, the foam can be crushed to avoid foam accumulation and overflow.

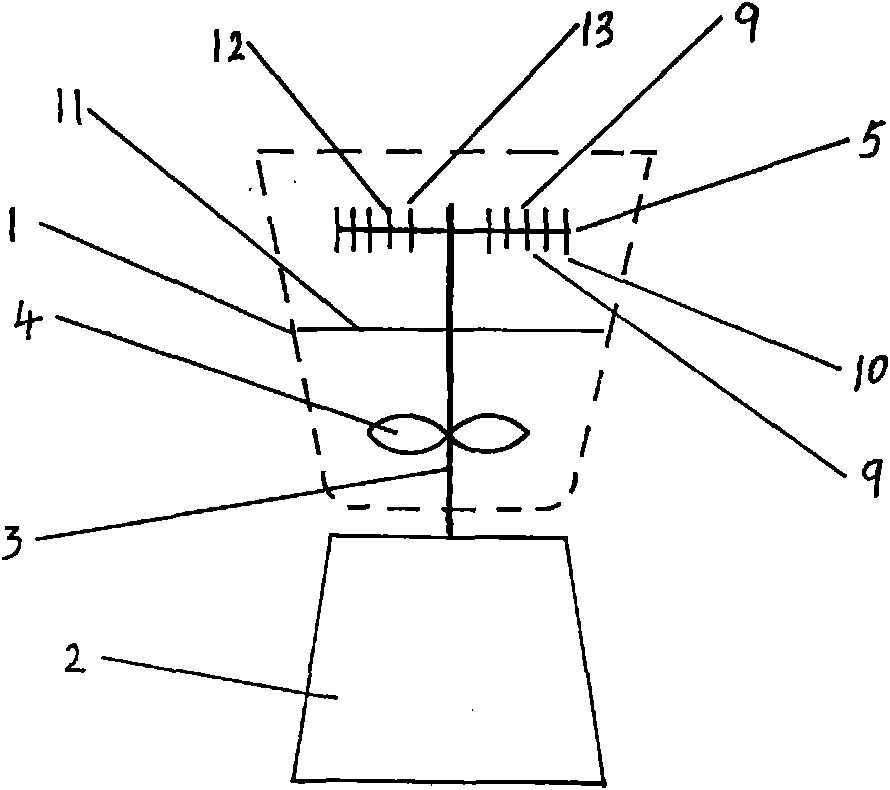

[0100] Such as image 3 As shown, the second embodiment of the present invention is a food processor with a high-efficiency rake-type defoamer, and the (crushing cutter) motor is a lower-mounted type.

[0101] The high-efficiency defoamer 5 in this embodiment is a rake defoamer 5 .

[0102] The barrel body 1 of the food processor is arranged on the su...

Embodiment 2

[0107] The rake defoamer 5 of the second embodiment is arranged on the crushing knife shaft 3, and its defoaming speed is about 12000 rpm.

[0108] In embodiment two, in order to obtain higher defoaming efficiency, or make the top of rake needle 12 improve to 100 millimeters from food material liquid surface 11 distances, thus not only make it be above (rotating state) food material liquid surface completely all the time, and Because the distance from the liquid surface is higher, the defoaming efficiency is higher. That is to say, for the same defoaming device (the shape, size and rotating speed are the same), its distance from the liquid surface 11 is different, and its defoaming efficiency is very different——the closer it is to the liquid surface 11, the lower the defoaming efficiency; The farther the surface is, the higher the defoaming efficiency is.

[0109] Such as Figure 4 As shown, the third embodiment of the present invention is a food processor with a high-effici...

Embodiment 3

[0114] The stirring paddle defoamer 5 of the third embodiment is arranged on the crushing knife shaft 3, and its defoaming speed is about 9000 rpm.

[0115] In the third embodiment, L1=L2=L3=50mm.

[0116] The operation and use process of the present invention are as follows: first add an appropriate amount of food material and water in the barrel body 1; the electric heating device on the food processor ( Figure 4 Not pictured in the middle) Food and water are heated to a certain temperature (such as 85°C); the pulverizing knife shaft 3 rotates and pulverizes the food (at this time, the stirring paddle type defoamer 5 is driven by the pulverizing knife shaft 3 to rotate together, because there is no Foam produces, stirring paddle type defoamer 5 is in idling state); The electric heating device on the food processor cooks pulp at full power; Due to the temperature rise, foam (saponin foam or normal boiling foam) is accompanied when cooking pulp. At this time, the crushing kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com