Micro drill and manufacturing method thereof

A micro drill bit and manufacturing method technology, applied in the direction of manufacturing tools, drill repairing, drilling tool accessories, etc., can solve the problems of large frictional resistance, poor hole thickness, poor positioning performance, etc., to improve cutting efficiency, improve positioning performance, cutting edge The effect of length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

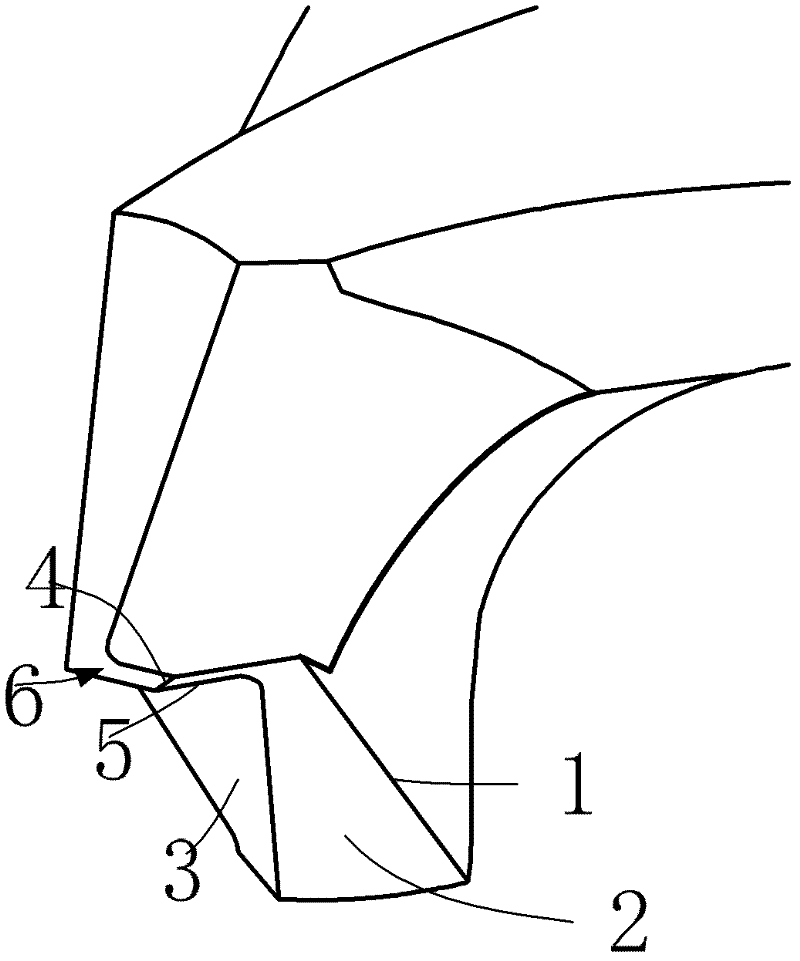

[0042] Embodiment one, such as Figure 1~5 Shown:

[0043] A micro drill, comprising two main cutting edges 1, each main cutting edge is provided with a first relief surface 2 and a second relief surface 3, the first relief surface 2 and the second relief surface The intersection line of surface 3 deviates from the position of the drill bit axis. The two first flanks 2 extend toward the axis of the drill bit to form two core cutting surfaces 6. The core cutting surfaces 6 intersect at the axis of the drill to form a chisel edge 4. The two core cutting surfaces 6 The side intersecting with the main cutting edge 1 forms two drill core edges 5 for cutting. The width of the chisel edge 4 is obliquely intersected with the core edge 5 of the drill point; the projections of the straight lines where the two main cutting edges are located on the cutting plane are parallel to each other.

[0044] In the present invention, the chisel edge 4 may also be perpendicular to the core edge 5...

Embodiment 2

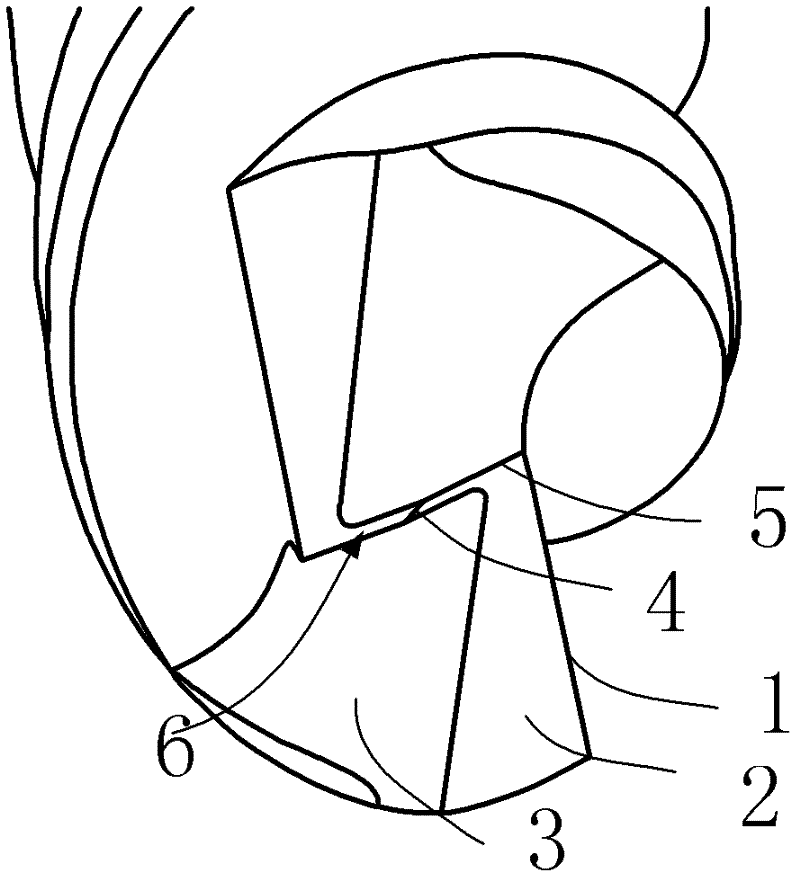

[0045] Embodiment two, such as Figures 6A-14 Shown:

[0046] A micro drill, comprising two main cutting edges 1, each main cutting edge is provided with a first relief surface 2 and a second relief surface 3, the first relief surface 2 and the second relief surface The intersection line of surface 3 deviates from the position of the drill bit axis. The two first relief surfaces 2 extend toward the drill bit axis to form two core cutting surfaces 6. The core cutting surfaces 6 intersect at the drill bit axis to form a chisel edge 4. The core cutting surfaces 6 and the The intersecting side of the main cutting edges 1 forms a drill core edge 5 for cutting. The width of the chisel edge 4 is obliquely intersected with the core edge 5 of the drill point; the projections of the straight lines where the two main cutting edges are located on the cutting plane intersect.

[0047] In the present invention, the chisel edge 4 may also be perpendicular to the core edge 5 of the drill p...

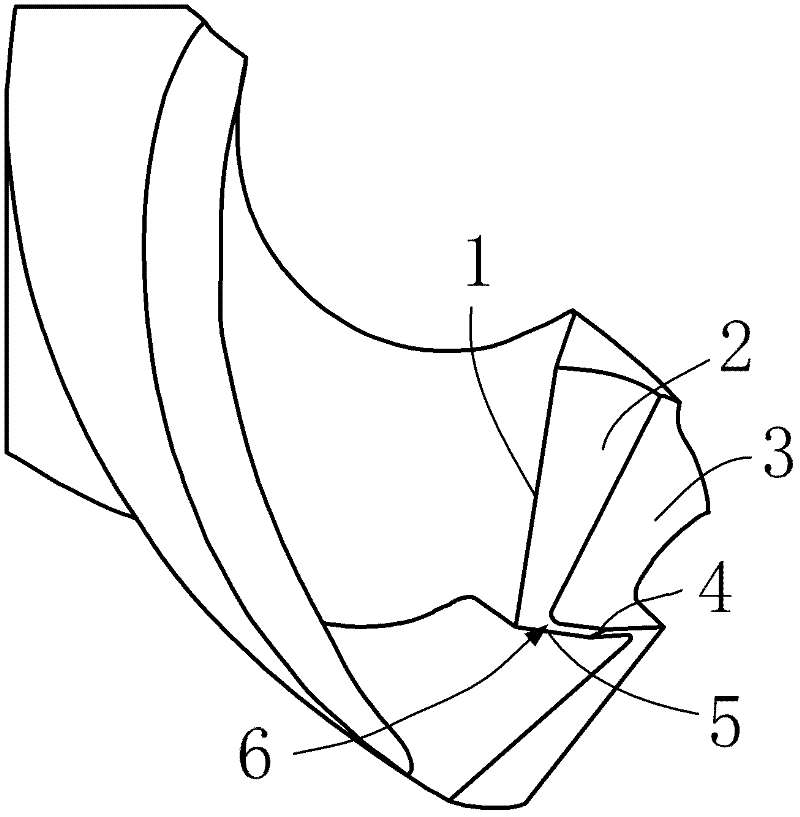

Embodiment 3

[0050] A micro-drill, comprising two main cutting edges 1, each of the main cutting edges is provided with a relief surface, and the two relief surfaces are provided with two core cutting edges intersecting at the axis of the drill bit at the intersection The core cutting surface 6 intersects at the axis of the drill bit to form a chisel edge 4 , and the side where the core cutting surface 6 intersects with the main cutting edge 1 forms a drill point core cutting edge 5 . The width of the chisel edge 4 is arranged obliquely and intersecting with the core edge 5 of the drill point.

[0051] In the present invention, the chisel edge 4 may also be perpendicular to the core edge 5 of the drill point. Drilling through the chisel edge 4, if the chisel edge 4 is too long, it will increase the drilling resistance and increase the wear of the drill bit; however, the material of the drill bit is not rigid enough, and the chisel edge 4 that is too short will cause too much stress to conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com