Machining and positioning device for inner bore

A positioning device and inner hole technology, applied in the field of mechanical processing, can solve the problems that the positioning method affects production efficiency and production management, and achieve the effects of saving tooling costs, reducing management costs, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention is described in further detail:

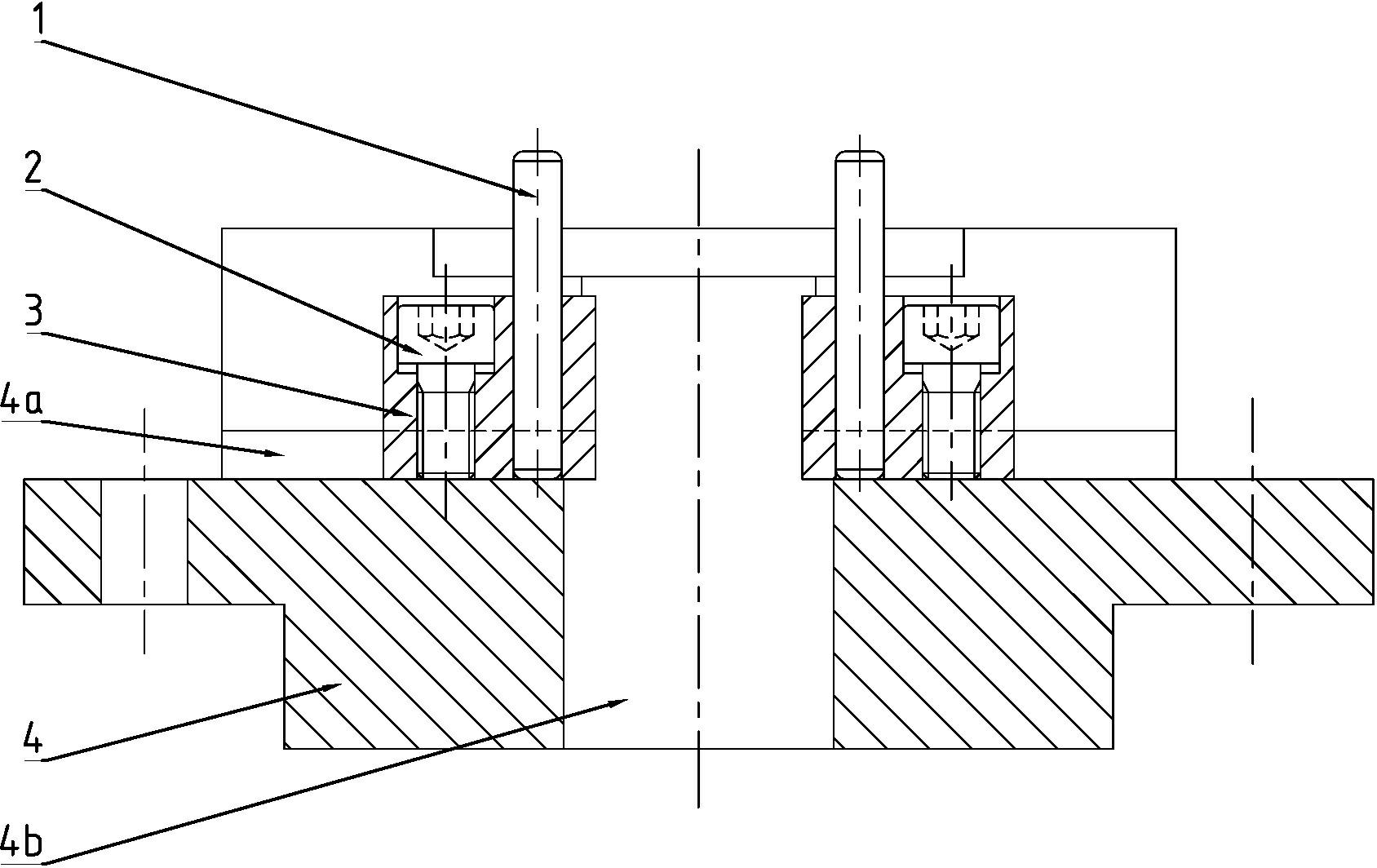

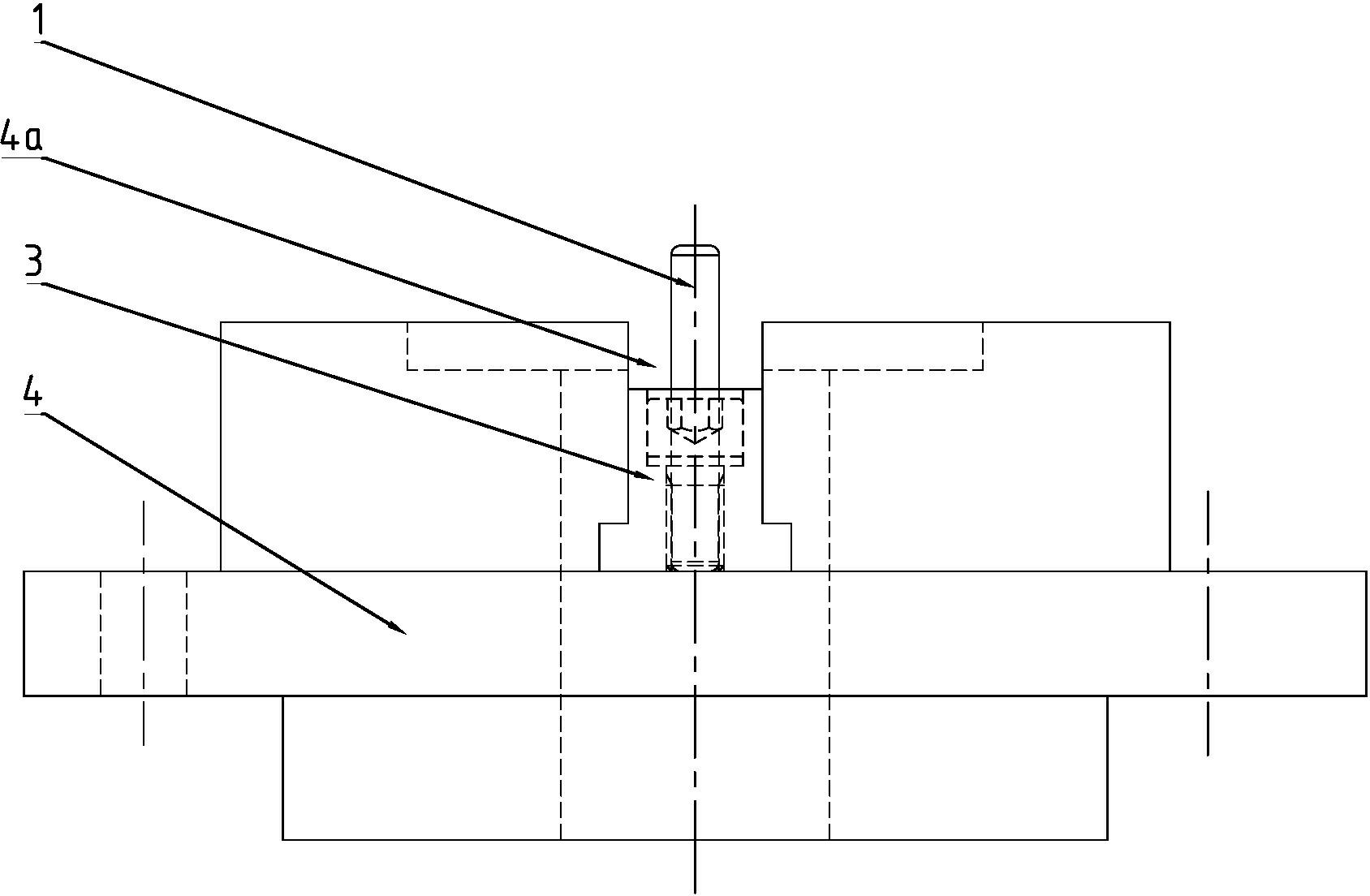

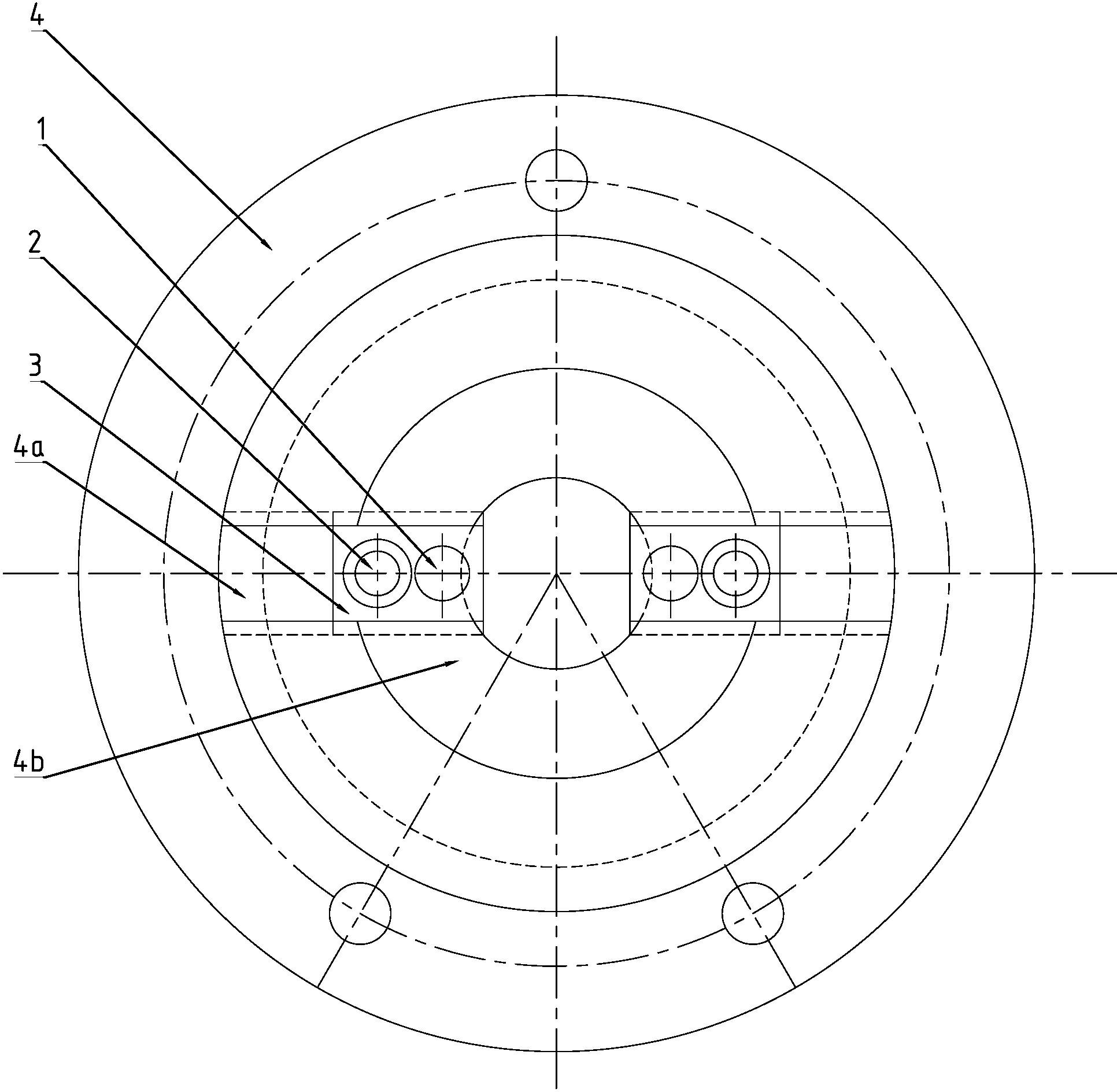

[0011] Such as figure 1 , figure 2 , image 3 As shown, a processing and positioning device for tapping the inner hole of the threaded cover plate of a spin-on filter includes a positioning pin 1, a screw 2, a positioning slider 3 and a positioning seat 4. The positioning seat 4 is composed of three sections of cylinders, which can be fixed on the machine tool table. The radial direction of the upper cylinder of the positioning seat 4 is provided with an inverted T-shaped slot 4a, and two T-shaped positioning slots are arranged in the T-shaped slot 4a. The slider 3 and the positioning slider 3 are respectively provided with a positioning pin 1. The positioning pin 1 is used for positioning with the existing symmetrical hole on the cover plate workpiece. The two positioning sliders 3 are respectively provided with through vertical screw holes. Use screws 2 to pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com