Bump Stop And Macpherson Strut

A technology of stopper and suspension, applied in the direction of suspension, elastic suspension, shock absorber, etc., can solve problems such as dissatisfaction, vulnerable bearings, and retaining buffer blocks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

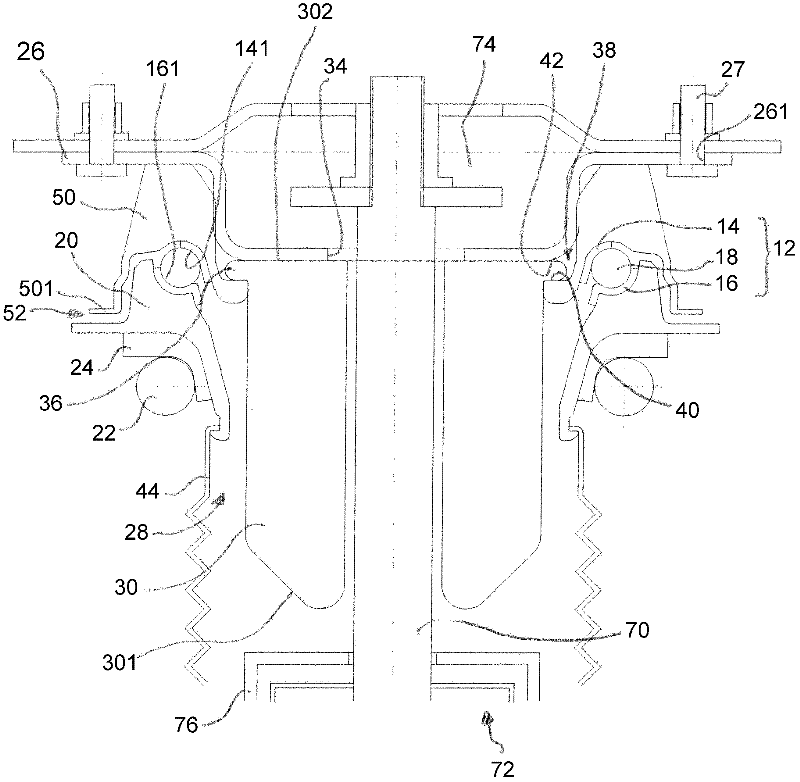

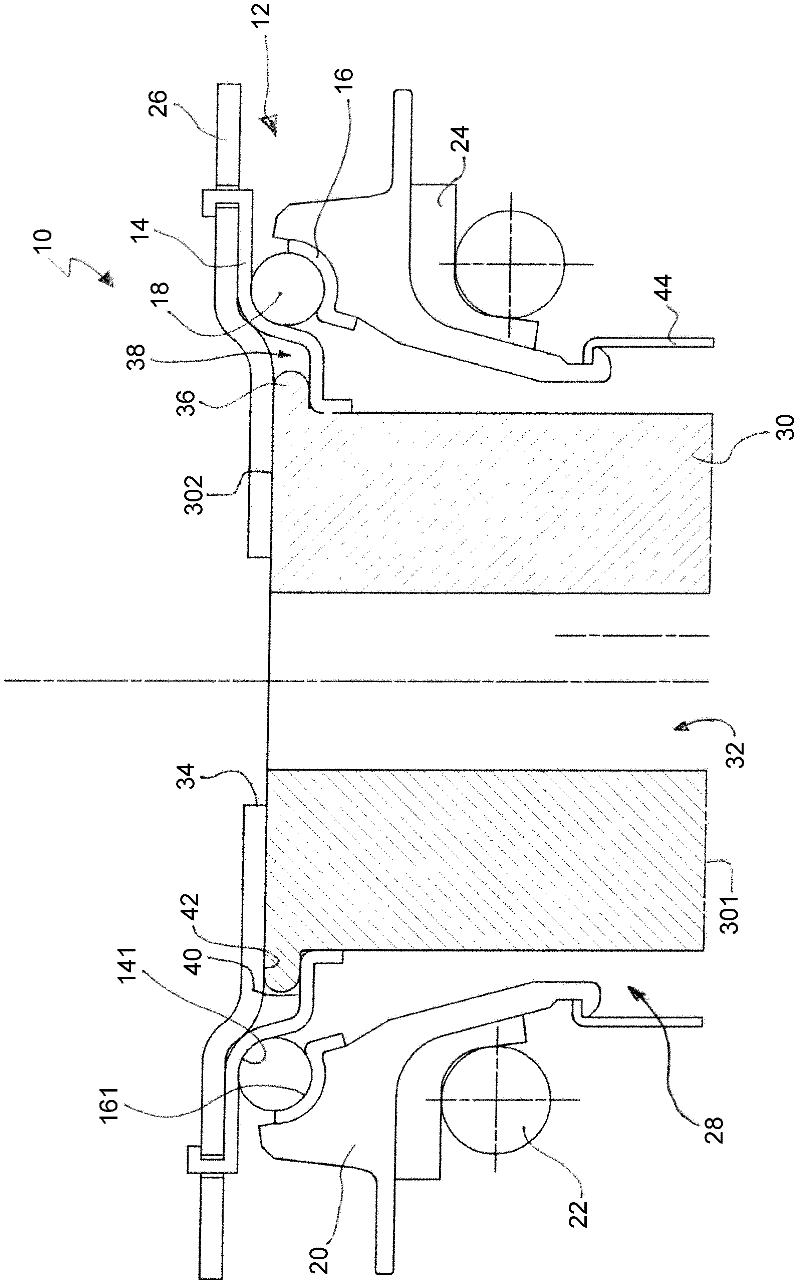

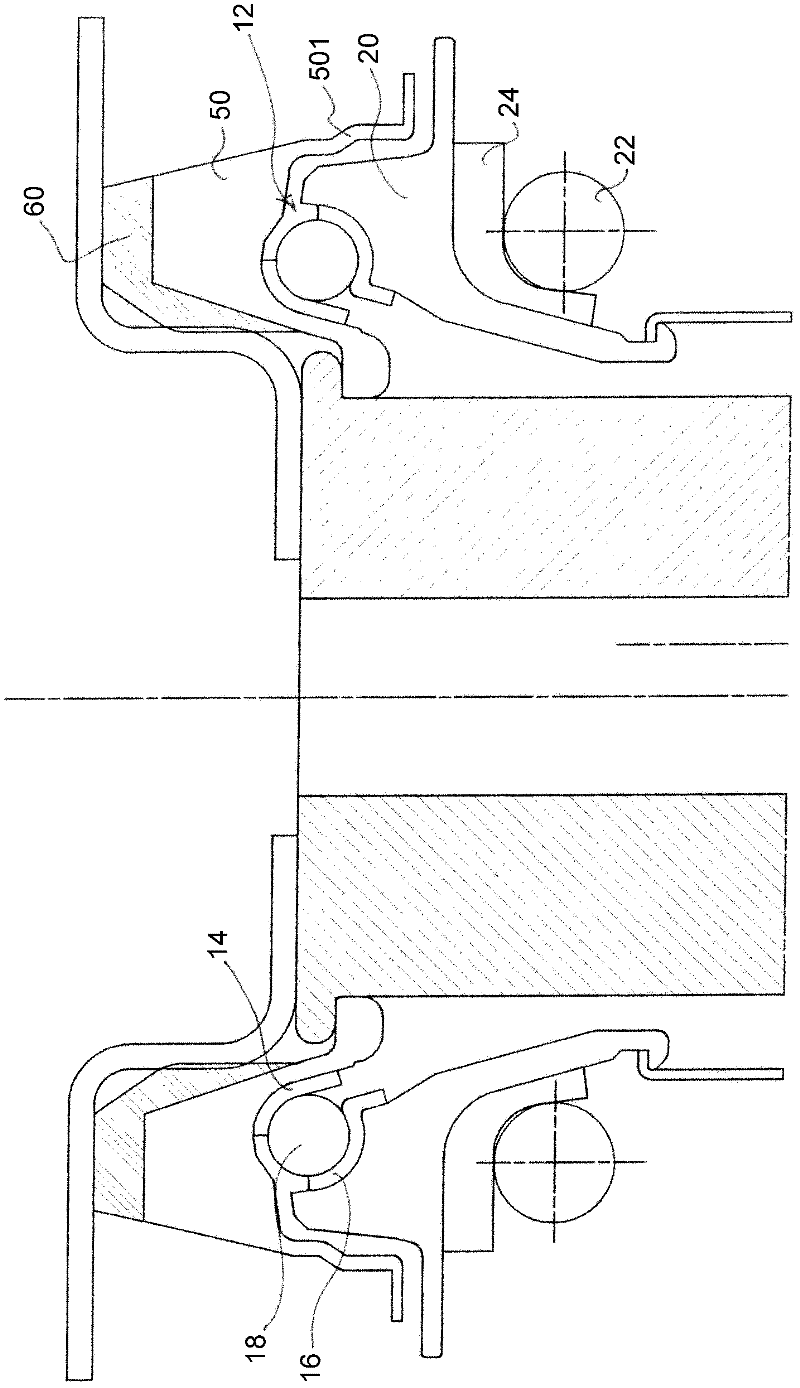

[0031] exist figure 1 In , a suspension stop 10 is represented constituting the upper part of the suspension strut at the interface between the suspension strut and the vehicle superstructure (actually a member of the body or vehicle chassis). This suspension stopper 10 comprises a roller bearing 12 consisting of an upper washer 14 and a lower washer 16, which respectively form a higher raceway 141 and a lower raceway 161, and the rolling bodies made of balls 18 rolls on said upper raceway 141 and lower raceway 161 . The support 20 is interposed between the lower washer 16 and the upper coiled portion of the coil spring 22 of the suspension strut. Optionally, a ring 24 made of elastic material can be placed between the support and the coil spring.

[0032] The interface for fixing the suspension stop to the vehicle superstructure (in this example the body) consists of a metal plate 26 provided with fixing holes 261 for screws 27 to be fixed to the body. A rigid cover 50 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com