Actuating system for a drum brake

A drum brake, braking system technology, applied in drum brakes, mechanically driven drum brakes, brake types, etc., can solve problems such as difficult combination, dependence on braking efficiency, and complex design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

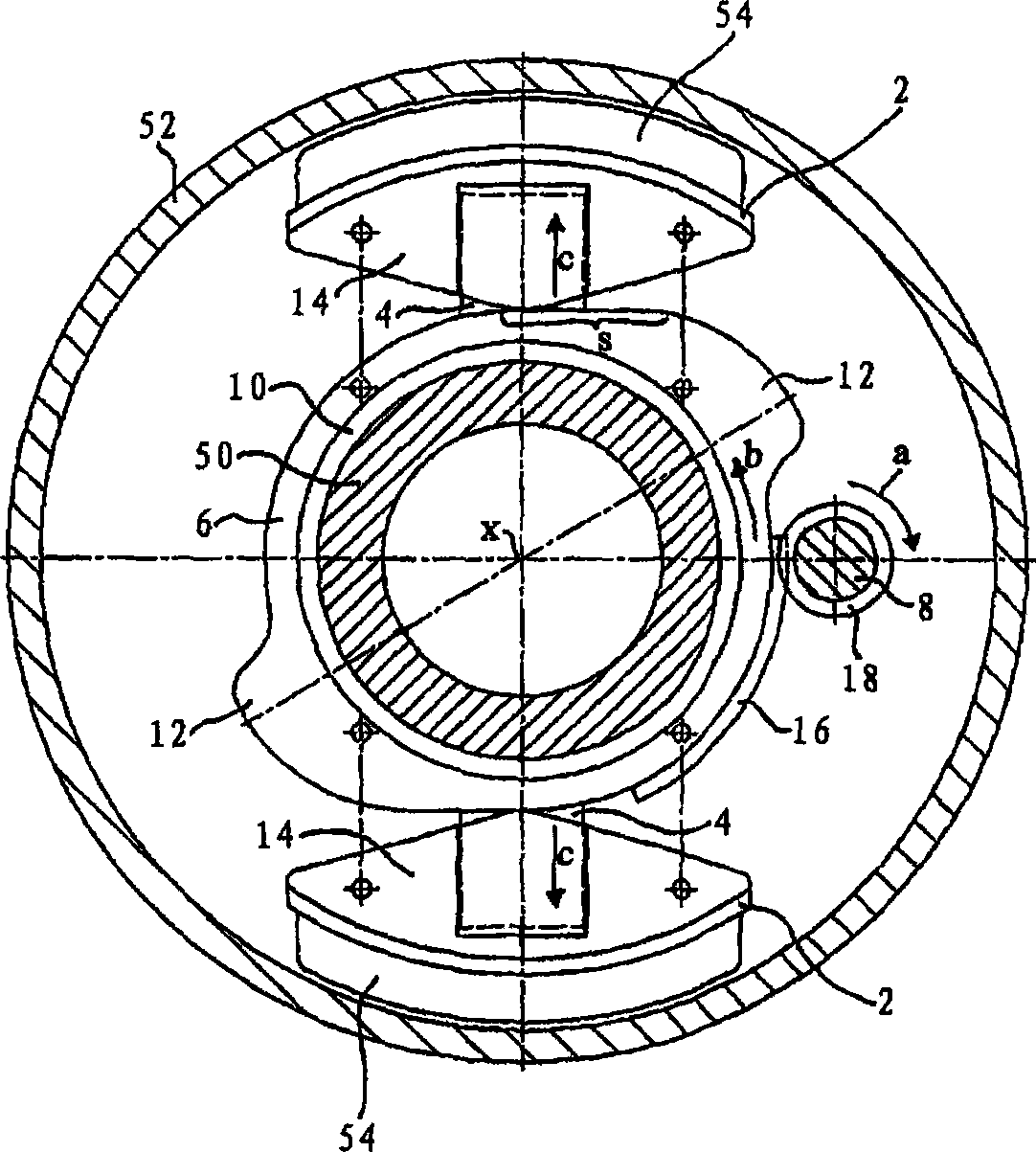

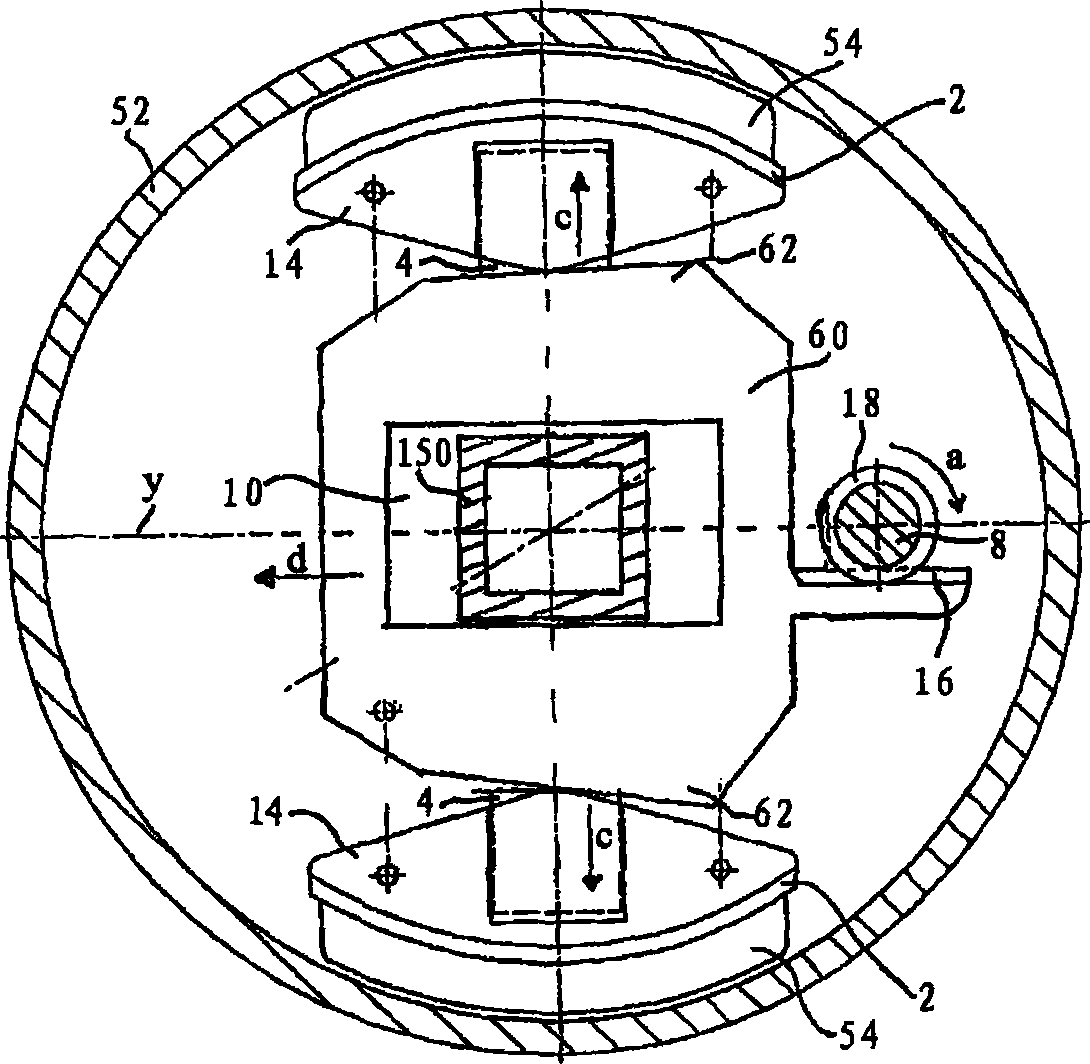

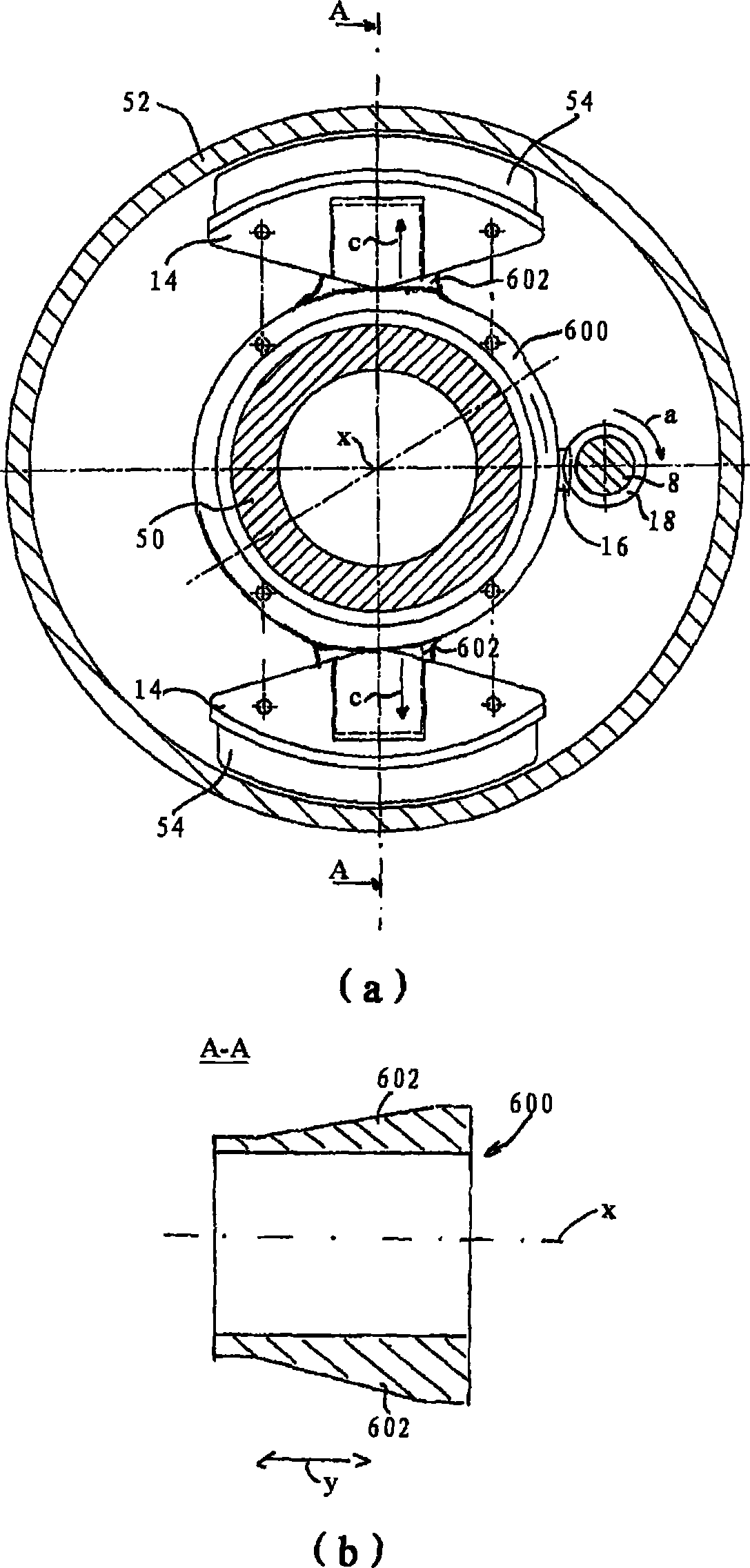

[0021] figure 1 is a sectional view of a first preferred schematic embodiment of an actuation system for a drum brake of a vehicle according to the invention. The system comprises a brake lining 2 , a brake carrier 4 , an actuating part 6 and a setting part 8 .

[0022] The braking element 6 is designed as a tubular or annular body, which is rotatably or rotatably supported on a rigid shaft body 50 via a bearing element (not shown). For this purpose, the shaft body 50 extends through the hollow space 10 of the actuating part 6 . The actuation member 6 is rotatable about an axis of rotation x, which also coincides with the axis of rotation x of the brake drum 52 and the longitudinal axis of the shaft body 50 .

[0023] The actuating part 6 has two opposing protrusions 12 designed such that the outer circumference of the actuating part 6 increases radially along the circumference in the contact zone s between the brake lining 2 and the actuating part 6 . It is particularly e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com