Water separation module, fuel filter separation assembly and assembly method thereof

A separation module and fuel filtration technology, applied in the direction of charging system, engine components, liquid fuel feeder, etc., can solve the problems of difficult collection, complex and bulky geometry, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

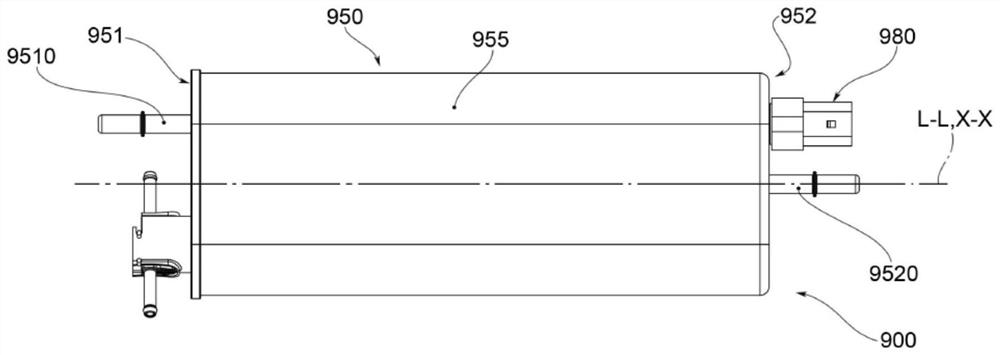

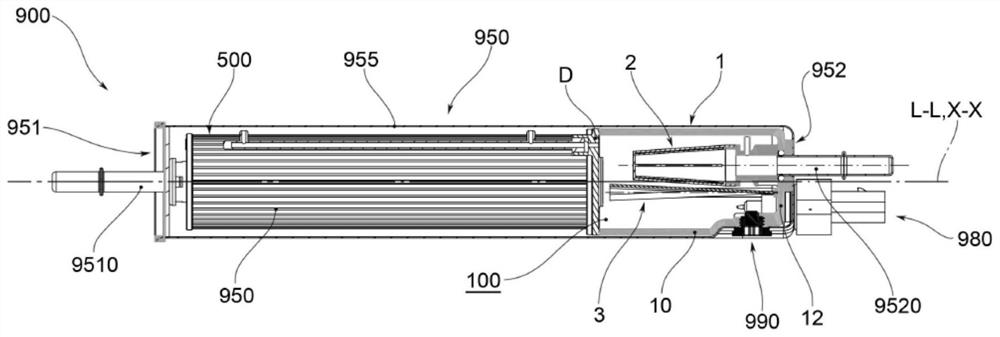

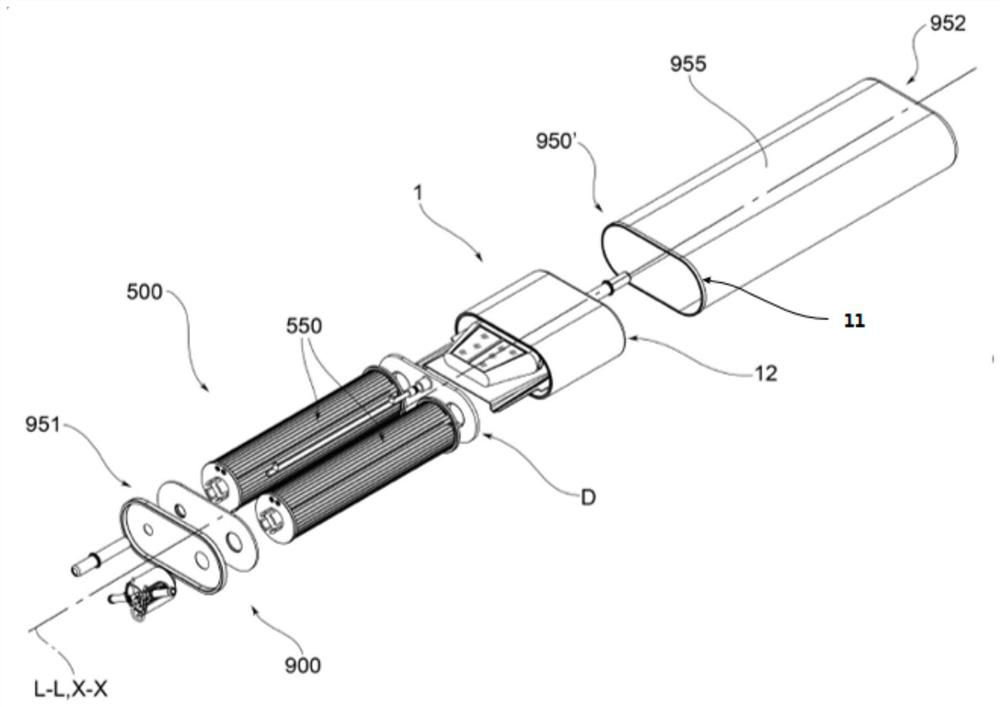

[0059] In the drawings, numeral 1 denotes a water separation module according to a preferred embodiment of the present invention. The water separation module 1 is specifically used for a fuel filter separation assembly 900 of a fuel circulation system of a vehicle. The fuel filter separation assembly 900 including the water separation module 1 is also the object of the present invention.

[0060] Both the water separation module 1 and the assembly 900 are in the context of the foregoing, which operate in a horizontal configuration, i.e., are housed in the vehicle in a substantially horizontal position; where "horizontal position" means that these components are A location substantially parallel to the ground plane in the direction of vehicle travel operates in the vehicle and is fluidly connected to the fuel circulation system. References to "lower", "upper", "side" etc. with respect to the area, location and / or components of the water separation module and fuel filter separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com