Cast-in-place concrete hollow five-star shaped pile with large diameter and construction method and special device thereof

A construction method and technology of special equipment, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as the effect of pile side friction resistance that has not been considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

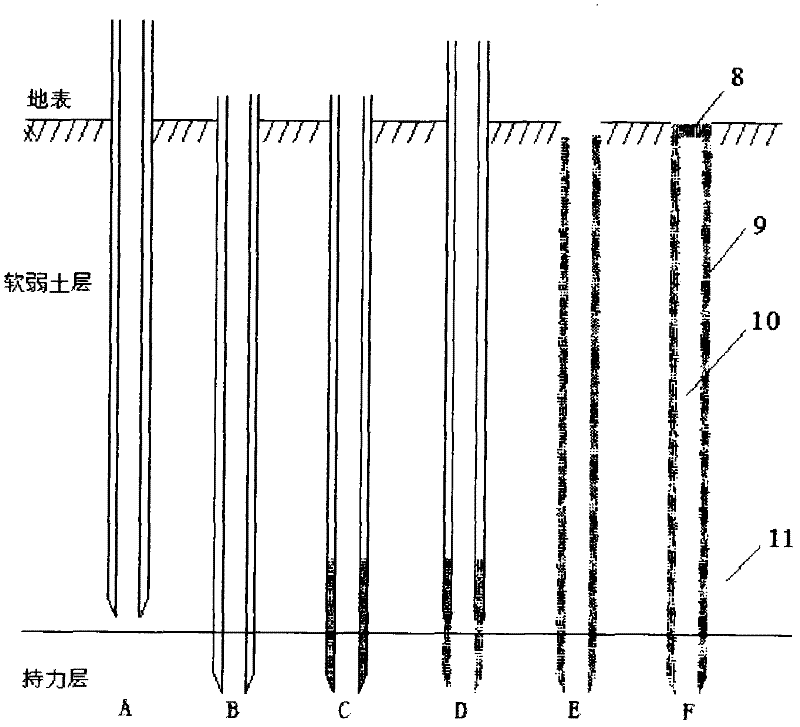

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

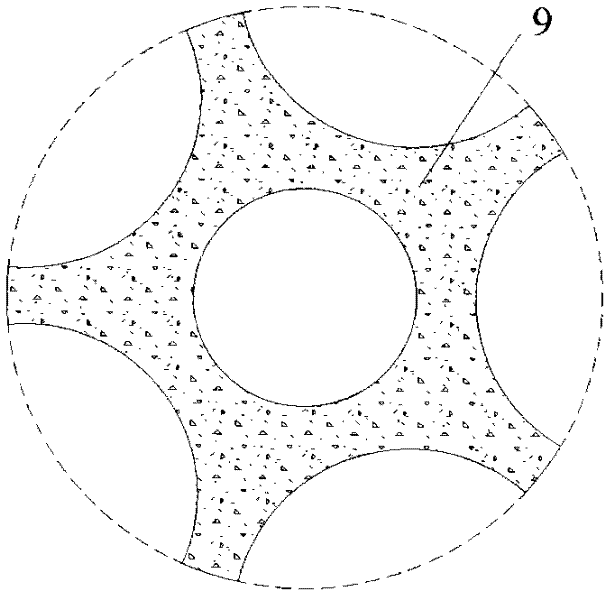

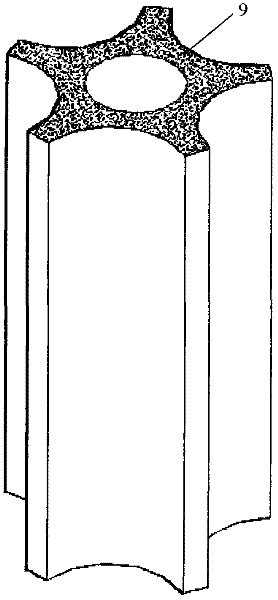

[0031] refer to figure 1 , figure 2 The invention discloses a cast-in-situ concrete large-diameter hollow five-star pile. The side surface of the pile body is composed of an angular plane formed by intersecting the pile body and an arc-shaped curved surface that is smoothly connected with the plane and is sunken into the pile body. The cross-section of the pile body is hollow five-star shape.

[0032] After the cast-in-place concrete large-diameter hollow five-star pile is piled, the middle is a cylindrical pile core soil, and the outside is a five-star concrete structure.

[0033] Further preferably, the inner diameter of the pile is 0.37-0.88m, the diameter of the outer circle is 1.0-2.0m, and the pile length can reach more than 25m.

[0034] Further preferably, the top of the pile body is poured with concrete to form a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com