Spring return type high-box locking mechanism

A spring return and locking mechanism technology, applied in the aviation field, can solve the problems of flight attendant or passenger injury, reduce friction, wear and other problems, and achieve the effect of convenient operation, high reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

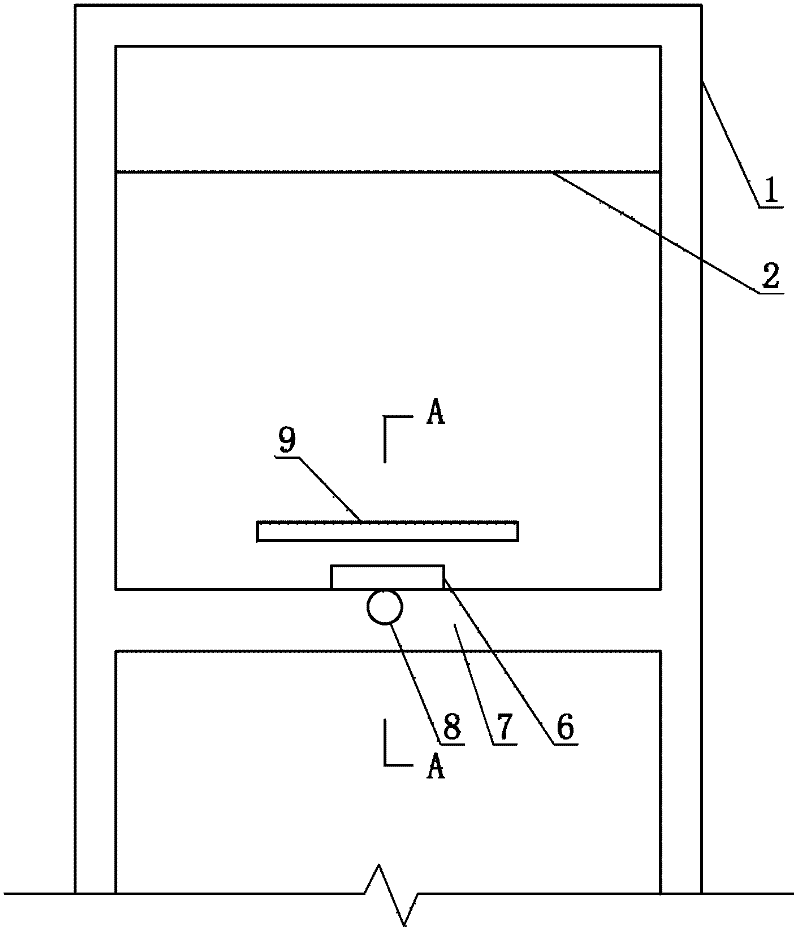

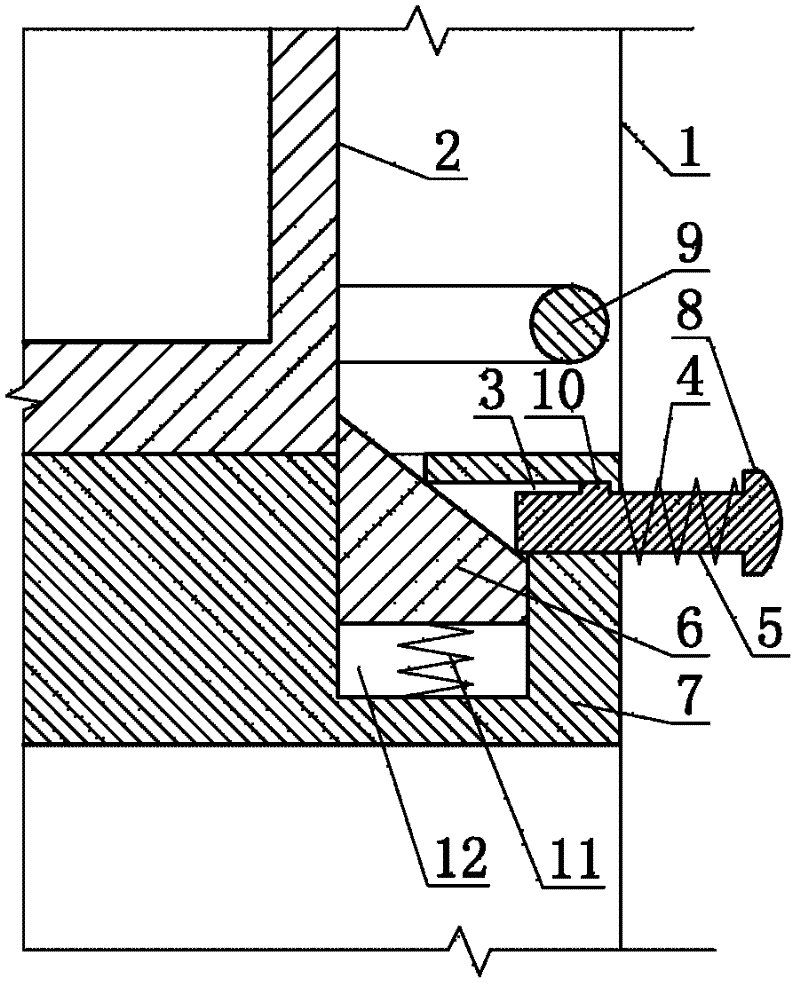

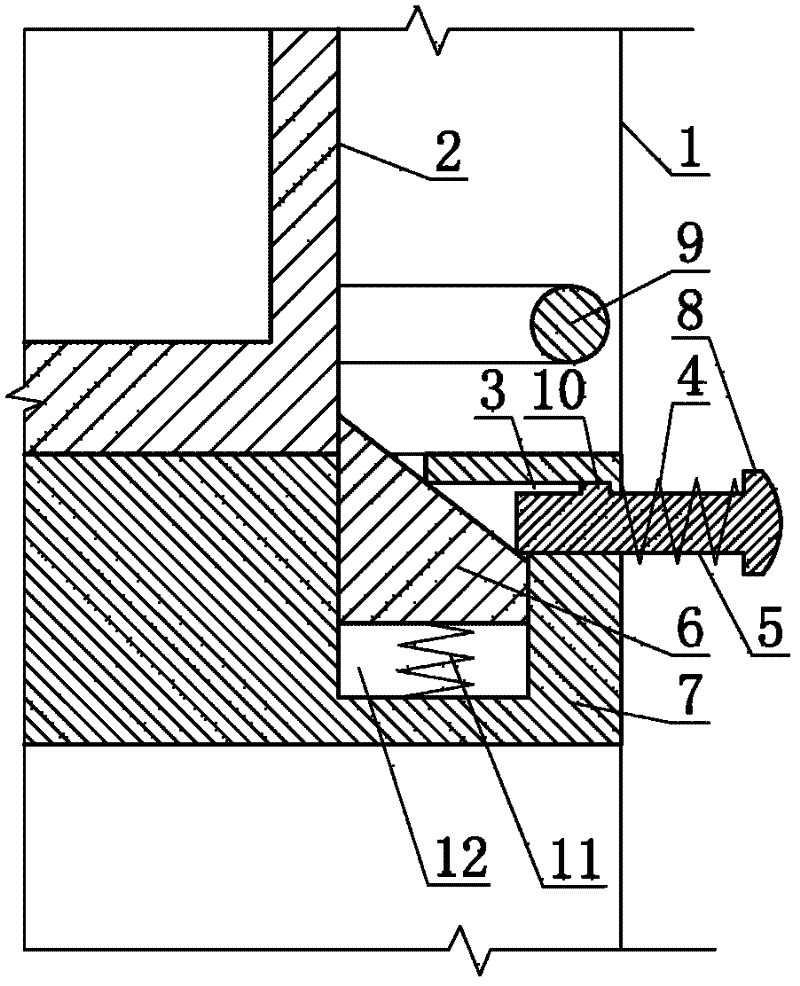

[0017] The spring return type high box locking mechanism consists of a cabinet body 1, a high box 2, a socket 3, a return spring 4, a button rod 5, a lock block 6, a drawer bottom plate 7, a button head 8, a handle 9, a protrusion 10, and a locking spring 11 And lock block cavity 12 constitutes. Wherein, the cabinet body 1 and the drawer bottom plate 7 horizontally fixed in the cabinet body 1 constitute a drawer cavity, and the high box 2 is located in the drawer cavity and forms a dynamic cooperation relationship with the drawer cavity. The outer end bottom of high case 2 has the handle 9 that is an integral body with high case 2. There is a distance between the upper surface of the high box 2 and the top surface in the drawer cavity, which is 1 / 5-1 / 4 of the height of the high box 2. The lock block cavity 12 is a vertical blind hole with a rectangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com