Cylinder-deactivation tappet device of engine

An engine and relative motion technology, applied in the direction of engine components, engine control, machine/engine, etc., can solve the problems of difficult engine cylinder technology and small installation space, and achieve high practical value, reduce fuel consumption, and reduce emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

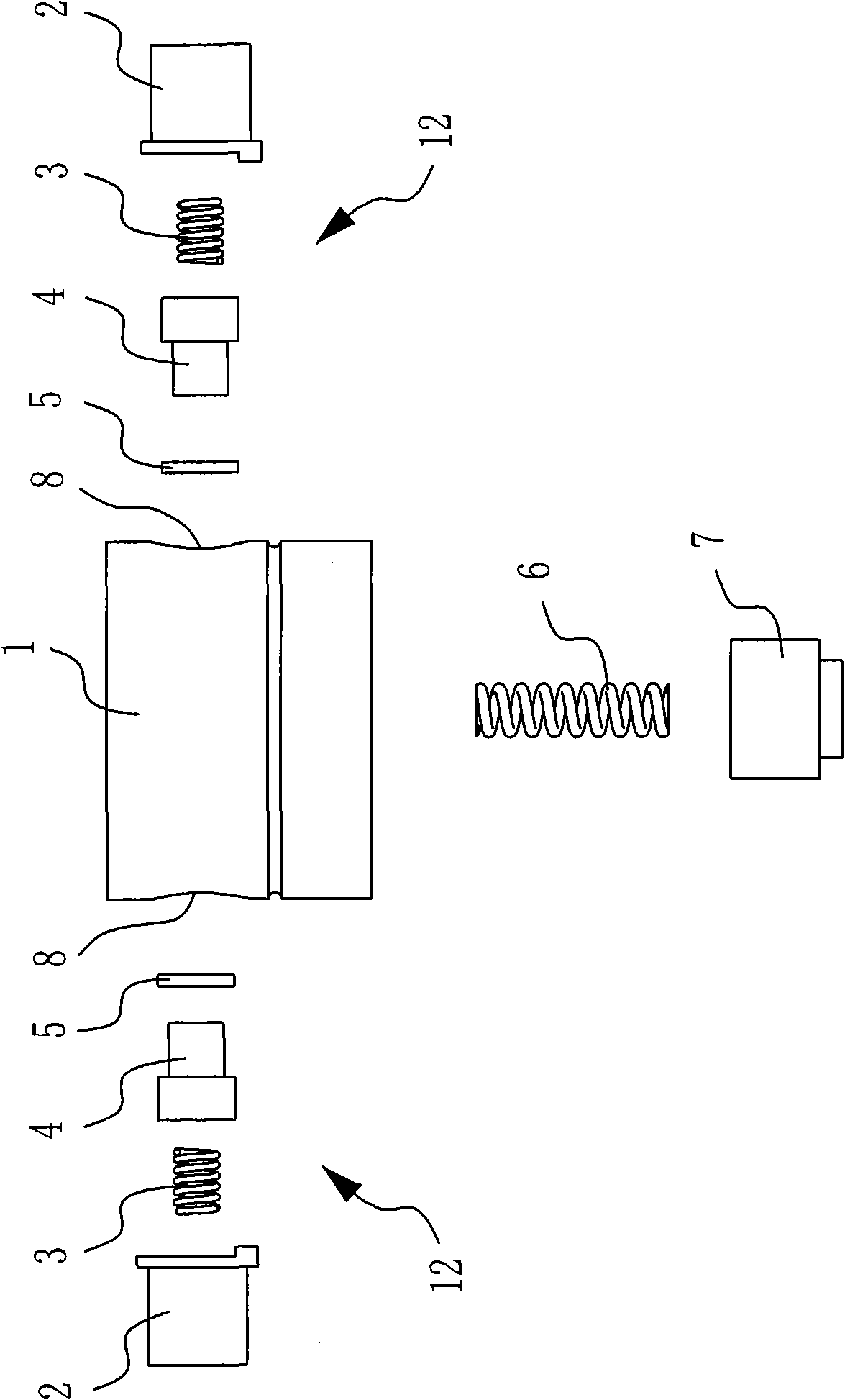

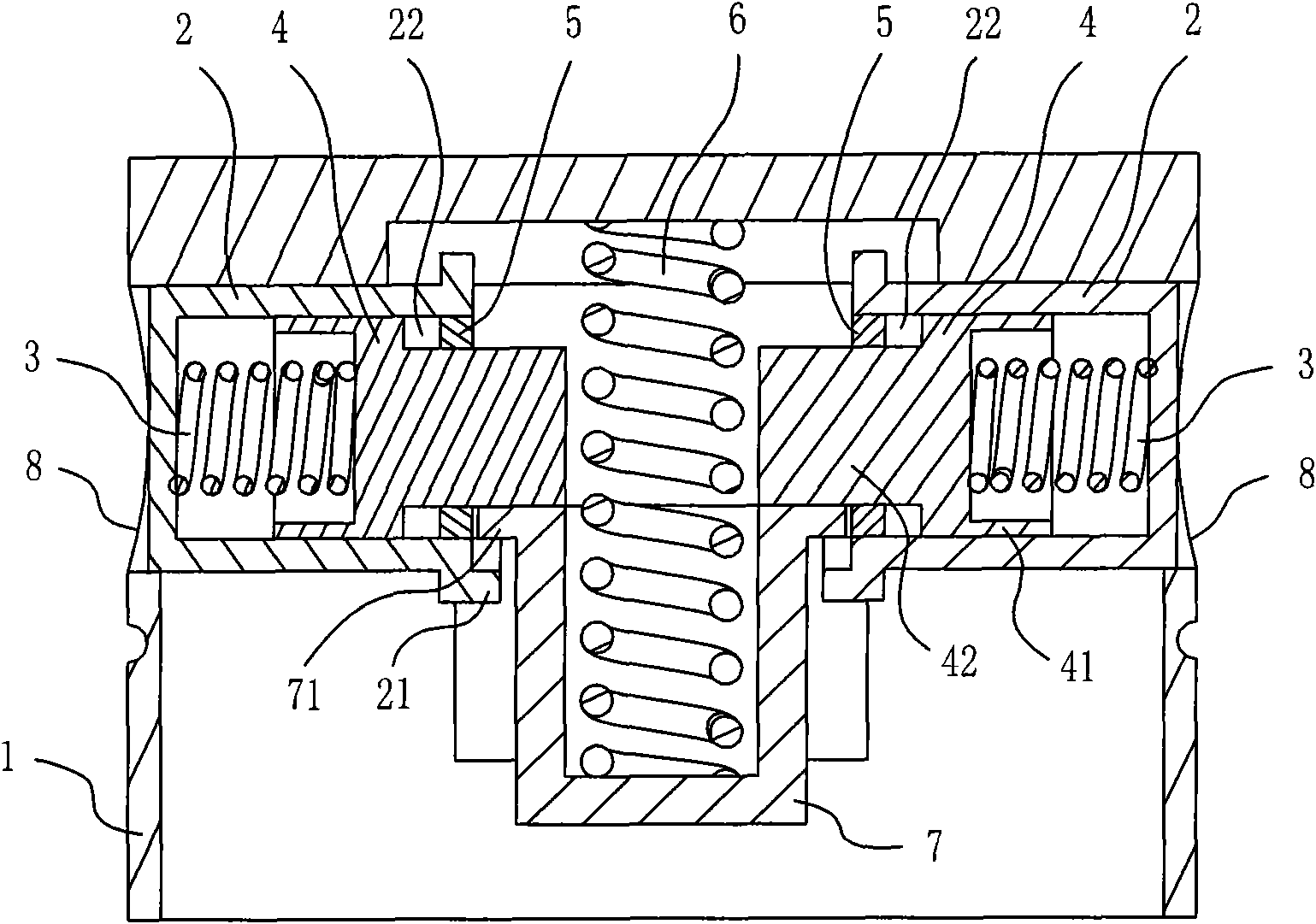

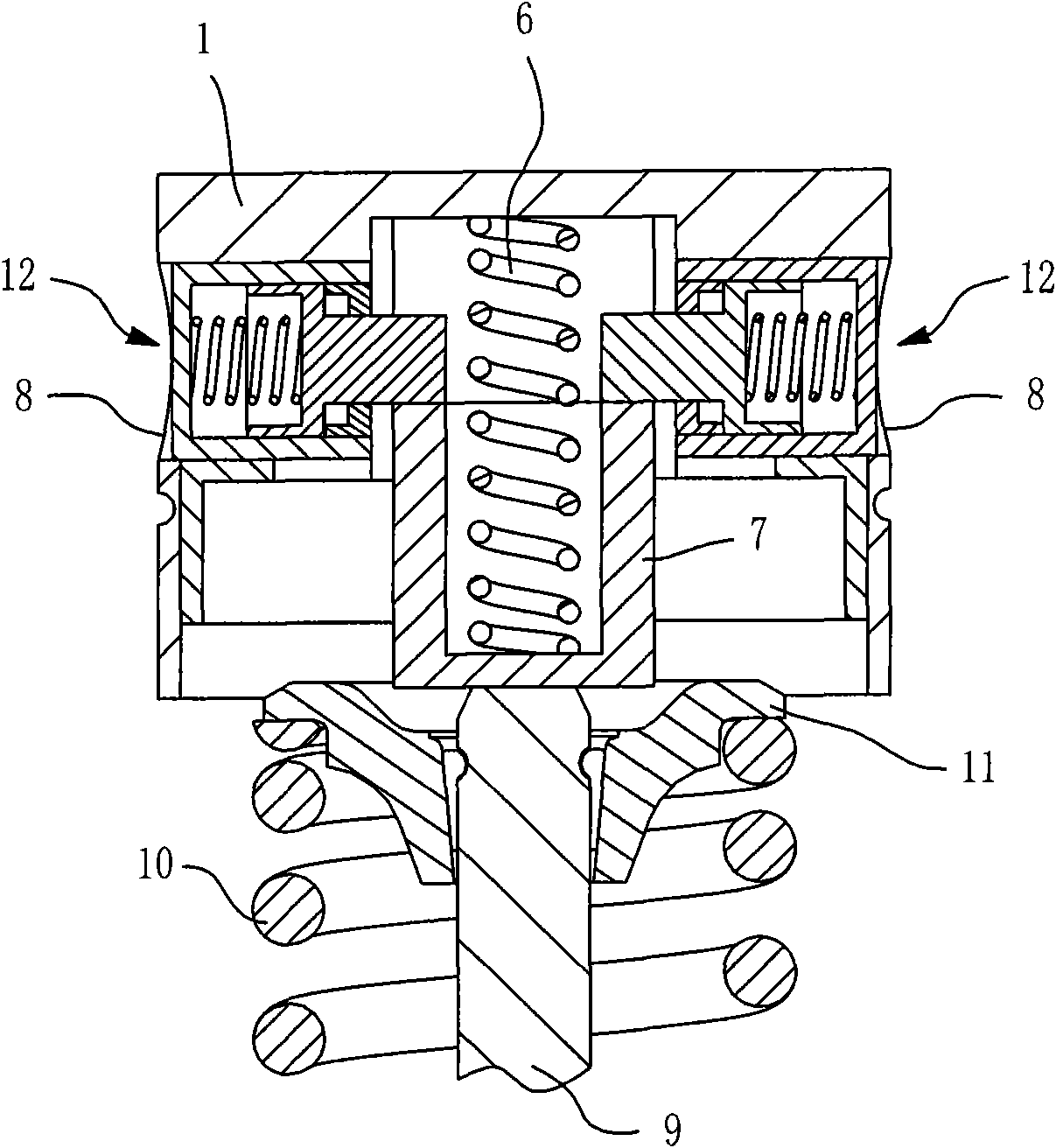

[0043] Please also see figure 1 and figure 2 , which schematically show the overall structure of a preferred embodiment of the engine deactivation tappet device of the present invention. In this preferred embodiment, the engine cylinder deactivation tappet device mainly includes a housing 1, a bracket 7 and a lock pin assembly 12, and these components will be described in detail below.

[0044] Such as figure 2 As shown, the housing 1 is covered on the valve mechanism, and the upper end of the housing 1 is a closed structure and is in contact with the cam on the camshaft of the valve drive group, and at the same time, the side wall of the housing 1 is also radially Two openings 8 are arranged symmetrically. In some other unshown embodiments, the above-mentioned openings can also be flexibly set according to actual needs, for example, three, four or more openings can be symmetrically set along the circumferential direction of the housing 1 .

[0045] The bracket 7 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com