Method for preventing air leakage between flue and pipeline of range hood

A range hood and flue technology, applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of easy aging of sealing mud, vibration of exhaust bellows, kitchen smoke pollution, etc., to reduce smoke pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

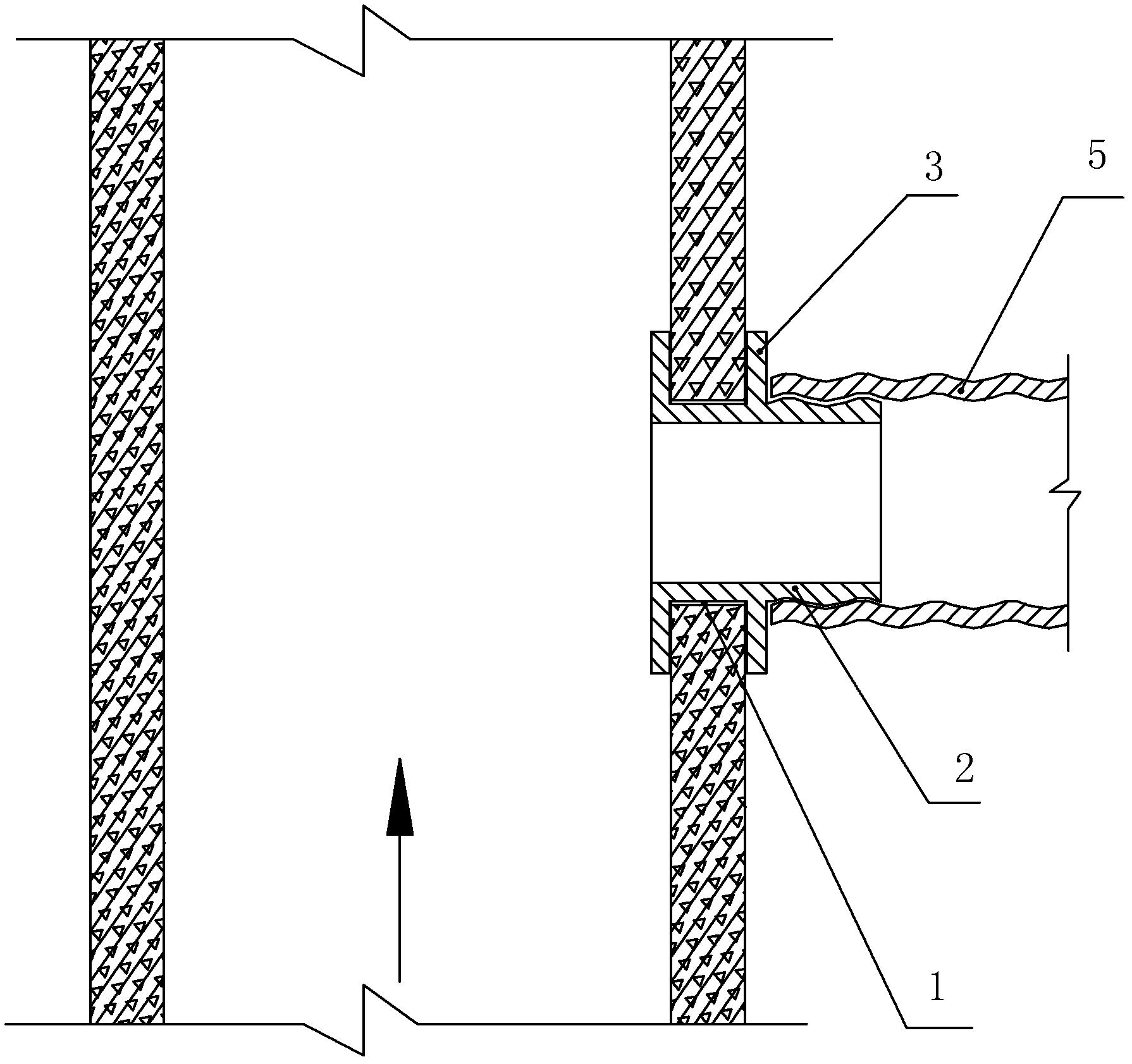

[0017] Such as figure 1 As shown, the method for preventing air leakage between the flue and the range hood pipe includes the following steps:

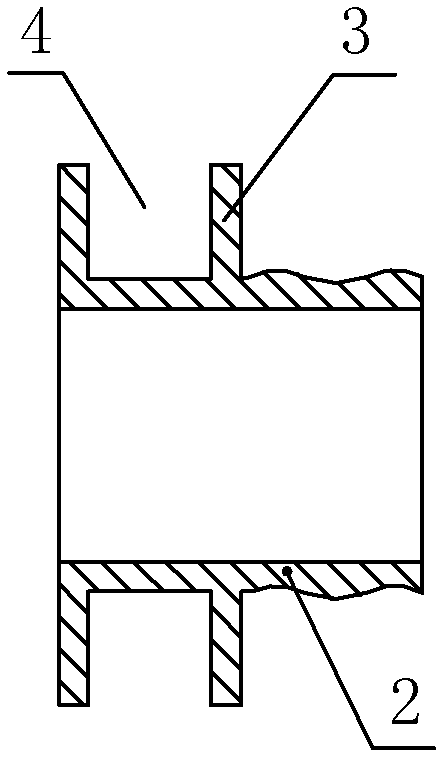

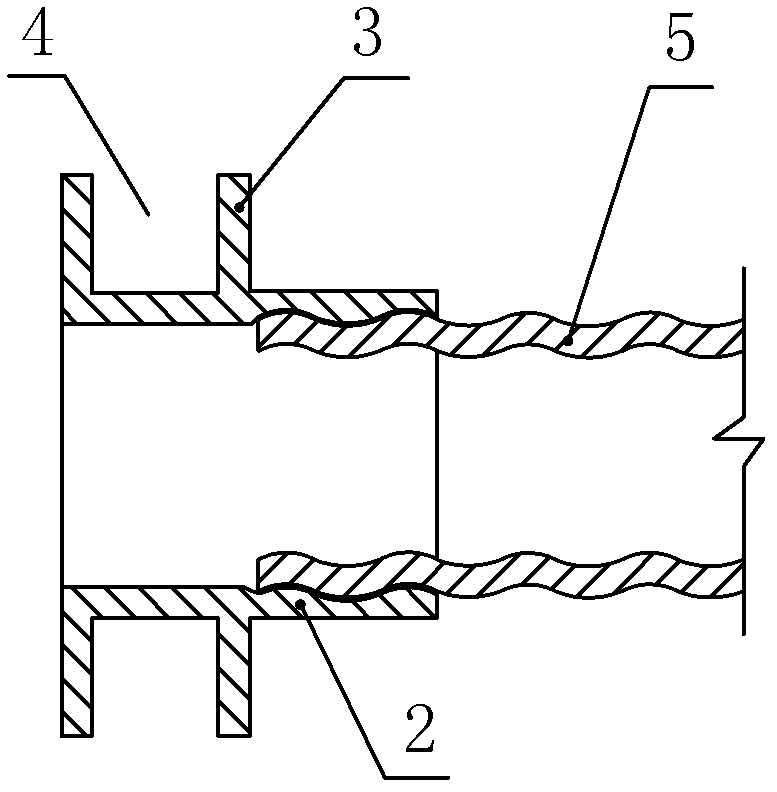

[0018] 1) Preparation of the connection head (including the sealing sleeve 3 and the bellows joint 2): as figure 1 , figure 2 As shown, the connector is composed of a sealing sleeve 3 and a bellows joint 2, one end of the bellows joint is connected to one end of the sealing sleeve 3 as a whole, and an annular groove 4 is arranged outside the sealing sleeve. Depending on the shape of the reserved smoke exhaust hole 1 (that is, corresponding to the shape of the reserved smoke exhaust hole 1 on the flue, it can be circular or square), the bellows joint is circular; the corrugation of the connector ( Or thread) The corrugation (or thread) of the pipe joint can be built in ( image 3 built-in) can also be a peripheral ( figure 1 , figure 2 for peripherals);

[0019] 2) Trim the reserved smoke exhaust hole 1 on the flue (correction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com