A kind of stencil belt thermal bonding method

A steel mesh and hot glue technology, applied in belt fasteners, belts/chains/gears, machinery and equipment, etc., can solve the problems of high burning temperature of belt rubber layer, damage to the occupational health of workers, shortened service life, etc. Achieve the effect of improving the level of cleaning and environmental protection, conducive to occupational health, and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In order to clearly illustrate the technical characteristics of this solution, the following describes the solution through specific implementations.

[0026]A method for thermal bonding of steel mesh bands includes the following steps:

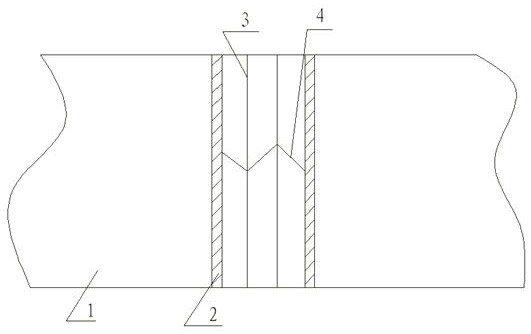

[0027]1. Remove the rubber on both sides of the damaged steel mesh. The splint 2 is fixed at both ends of the damaged section of the steel mesh belt, the splint spacing is 200mm~300mm, and the splint 2 includes two bent plates whose side width is not less than 60mm. The four bent plates are fixed in pairs on the upper and lower sides of the two ends of the damaged section of the steel mesh belt. The bent plates are provided with connecting holes located on the outside of the steel mesh belt. The opposite bent plates pass through the connection The fixing bolts of the holes are fastened together. In order to reduce the production cost, the splint of this embodiment is made of angle steel ∠63×63×6.

[0028]After the splint is fixed, the upper side rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com