Utilization method of magnesium condensation heat generated during pidgeon process magnesium smelting

A technology of magnesium smelting and water cooling, which is applied in the field of energy saving and consumption reduction in the metal magnesium smelting process, can solve the problems of affecting normal production and high energy consumption, and achieve the effects of dense crystallization, improved economic benefits, and reduced burning phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

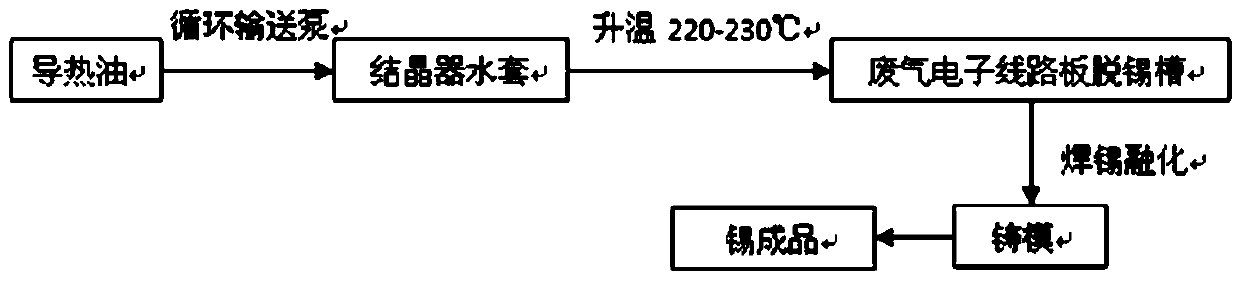

[0017] A method for utilizing the heat of condensation of magnesium in the Pidgeon method for smelting magnesium, comprising the steps of:

[0018] In the first step, the water cooling in the Pidgeon process of magnesium smelting is changed to heat conduction oil cooling, and the circulating pump is used for pressurized transportation;

[0019] In the second step, the heat transfer oil is pressurized to 0.1-0.2MPa through the circulating delivery pump, and delivered to the inlet of the water jacket of the crystallizer;

[0020] In the third step, the heat conduction oil at the inlet of the water jacket of the reduction crystallizer enters the water jacket of the crystallizer under a pressure of 0.1-0.2 MPa. The heat conduction oil absorbs the condensation heat of the magnesium reduction process. The outlet of the water jacket of the crystallizer flows into the waste electronic circuit board deleading tin tank at the bottom of the crystallizer water jacket;

[0021] In the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com