Clamping jig and system for inspecting spacer grids for nuclear fuel assembly

一种核燃料组件、定位格架的技术,应用在燃料元件的组装、核工程、核能发电等方向,能够解决工作效率低下等问题,达到提高作业效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] First of all, the terms and words used in this specification and claims are not limited by the usual or dictionary meanings, but should be properly defined as the terms used by the inventor to best describe the present invention, based on technical principles, and Interpretation is the meaning and concept contained in the technical idea of the present invention.

[0049] Therefore, the embodiments described in this specification and the structures shown in the accompanying drawings are only the most preferred embodiments of the present invention, and do not represent all technical ideas of the present invention. Various equivalents and modifications of the contents.

[0050] Hereinafter, description with reference to drawings is as follows.

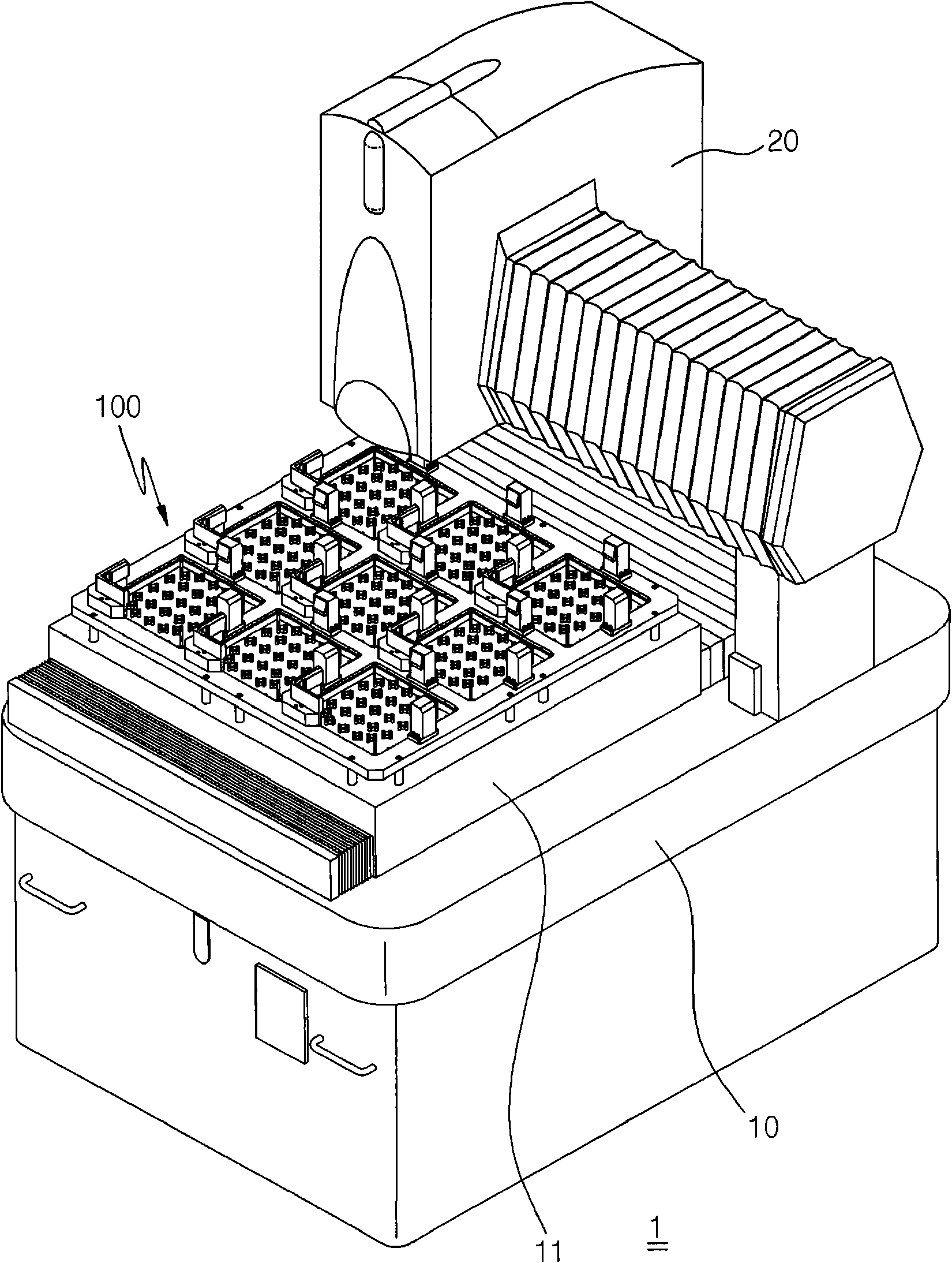

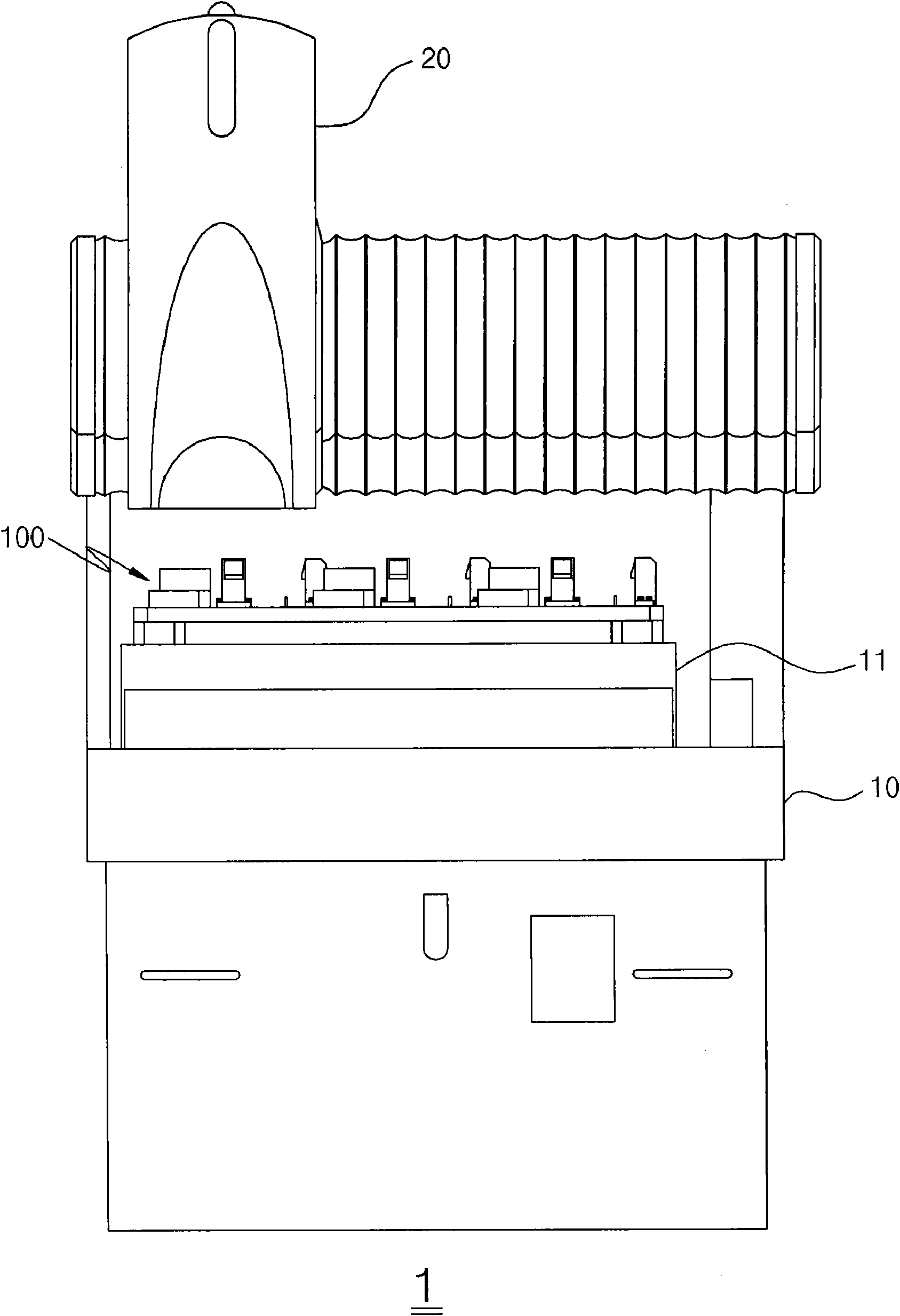

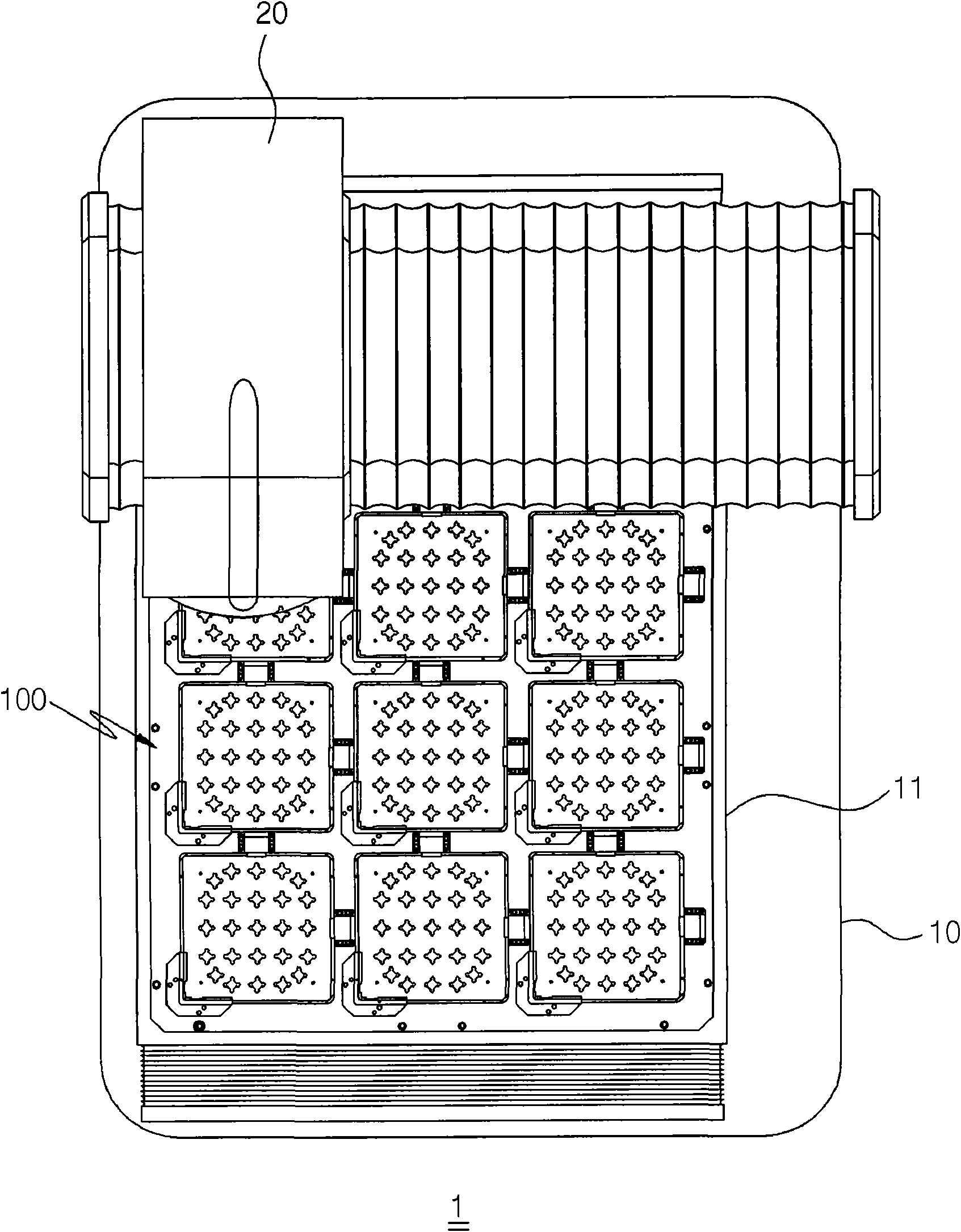

[0051] Such as Figure 1 to Figure 3 As shown, the nuclear fuel assembly positioning grid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com