Pipeline port hysteresis buffer demagnetization method and demagnetizer

A degaussing method and pipeline technology, applied to magnetic objects, electrical components, circuits, etc., can solve problems such as unsatisfactory degaussing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

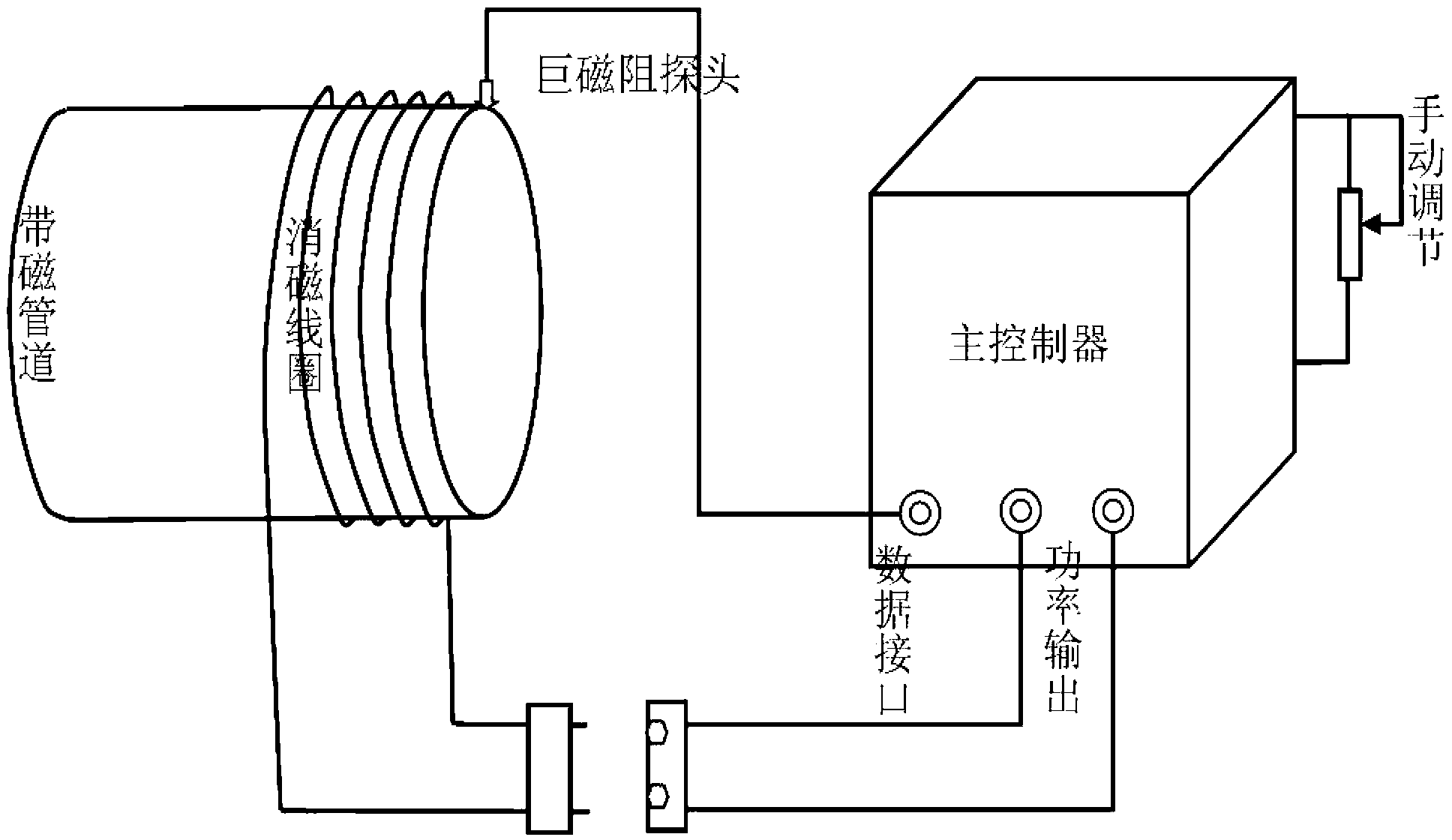

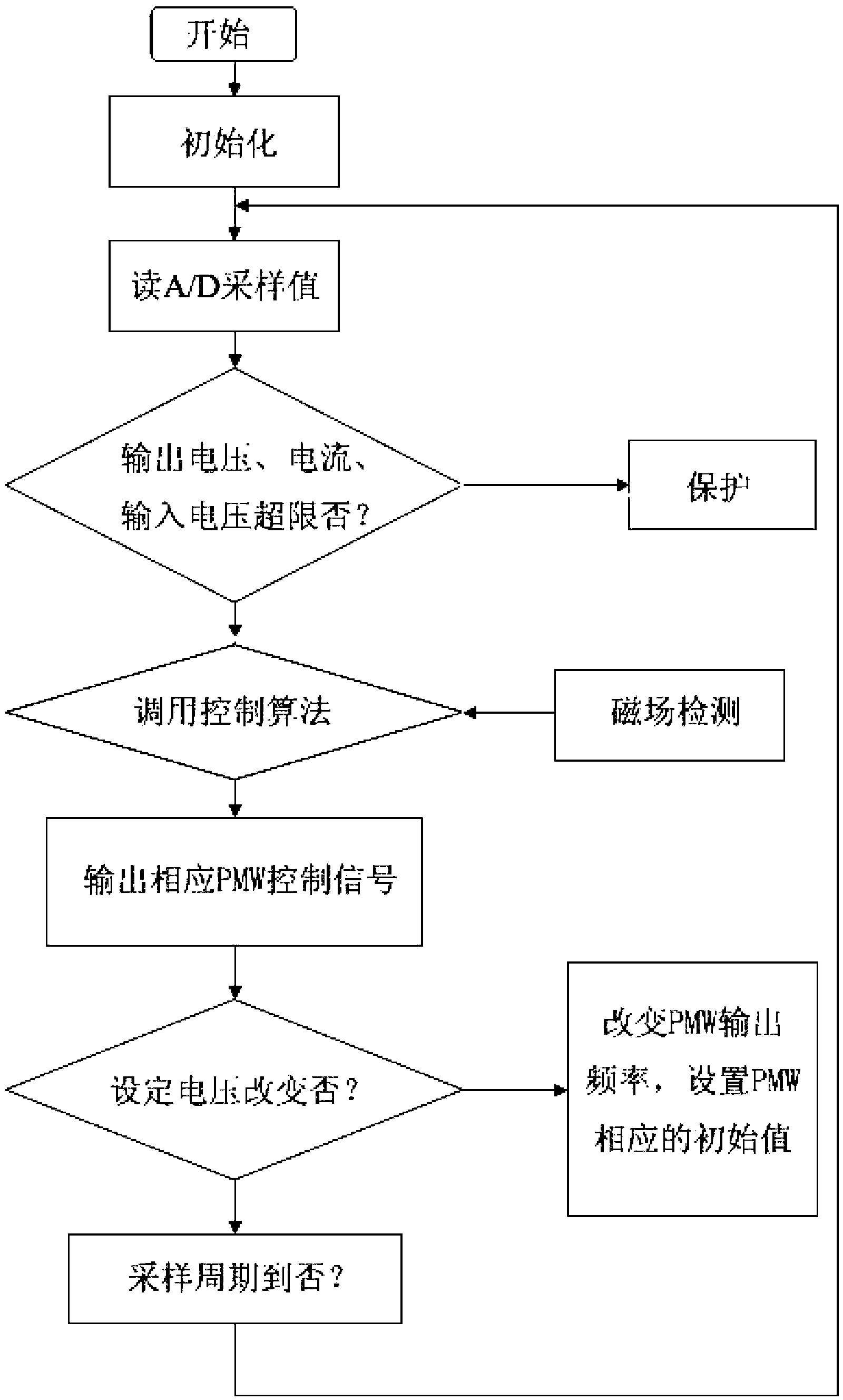

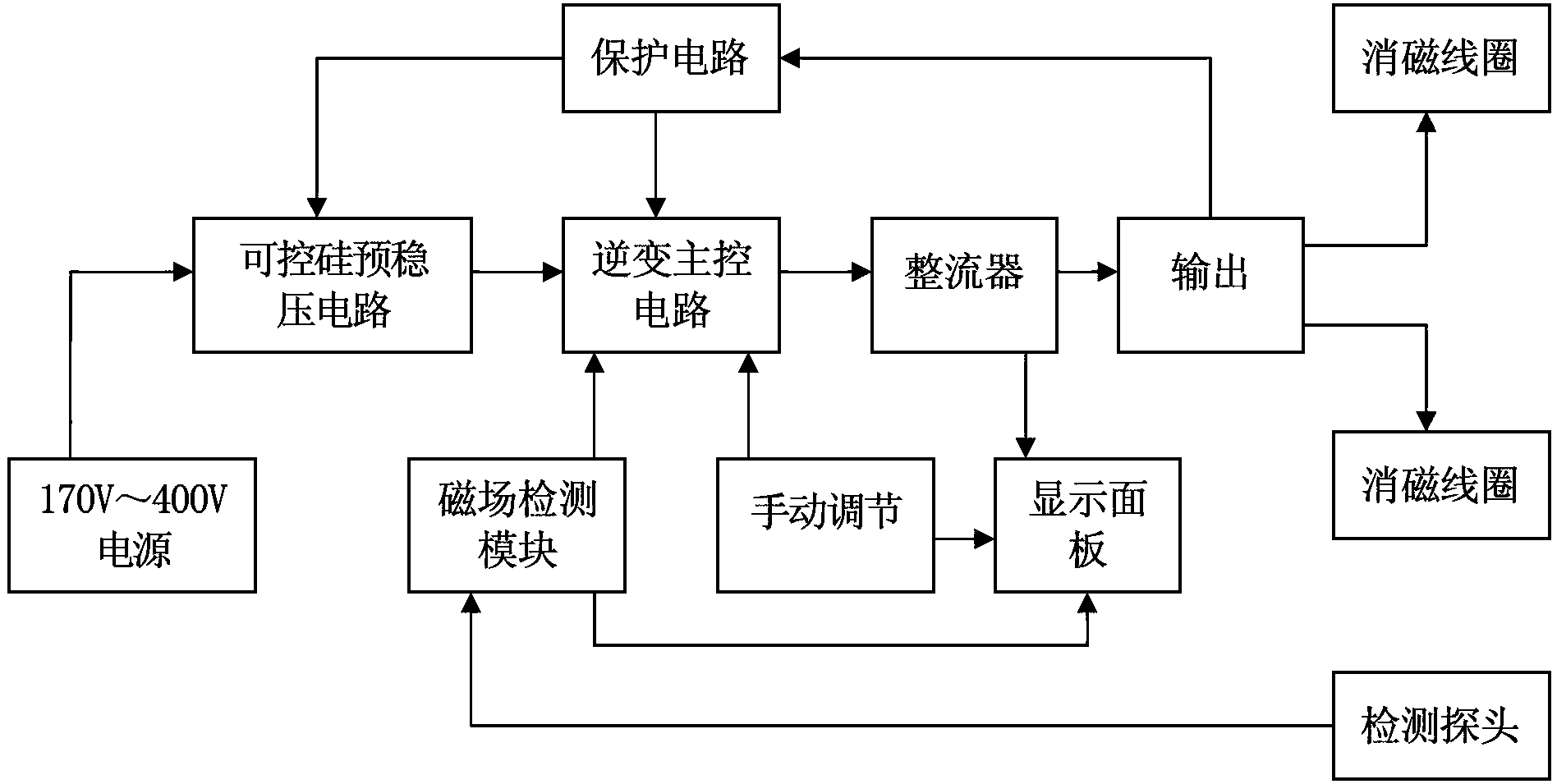

[0060] Embodiment. This example is an experimental method and prototype, and its constitution is as Figure 3-Figure 7 shown. It consists of thyristor pre-stabilization circuit, inverter main control circuit, rectifier, regulator, magnetic field detection module, display panel, protection circuit, degaussing coil; The output of the silicon pre-stabilization circuit is connected to the inverter main control circuit, while the output is connected to the regulator output of the display panel to the inverter main control circuit, and the output of the magnetic field detection module connected to the detection probe output is also connected to the inverter main control circuit, and the inverter main control circuit The output of the circuit is connected to the rectifier, and the output of the rectifier has three routes: one is connected to the protection circuit, the output of the protection circuit is connected to the thyristor pre-stabilization circuit and the inverter main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com