Bearing disk for detaching axel-hung box bearings of locomotive

An axle-holding box and load-bearing plate technology is applied in the field of special technical equipment for dismantling and disassembling railway locomotives, which can solve the problems of complicated operation procedures, occupying a lot of driving resources, and labor intensity of workers, etc., achieving convenient operation, reducing labor intensity, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

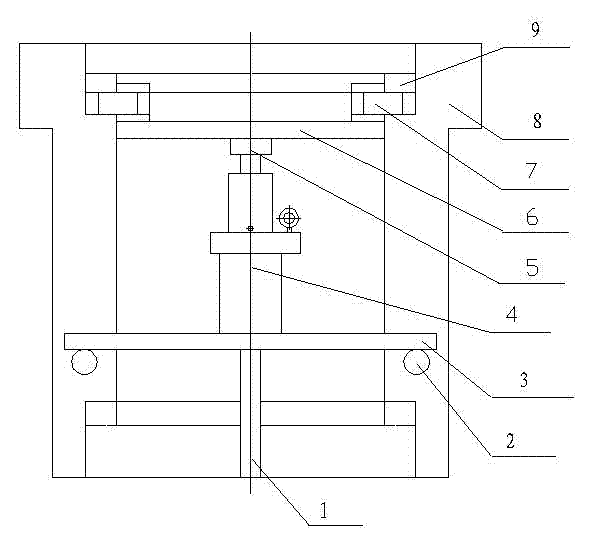

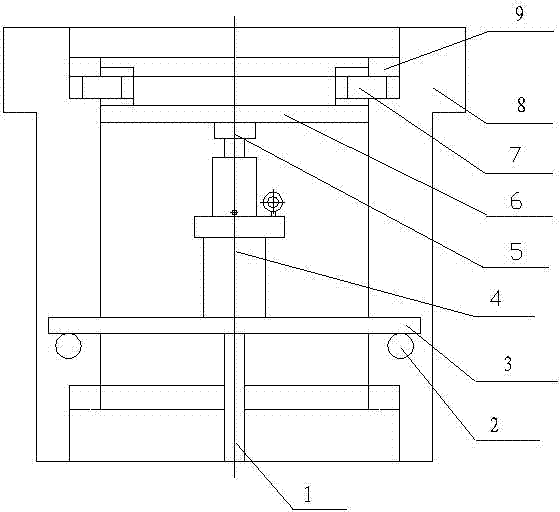

[0008] As shown in the attached drawing, the ejector rod 1 is directly placed on the work surface, and the clearance between the pin 2 and the axle box 8 is 1MM, and the pin 2 can be easily pulled out. It is placed under the load-bearing plate 3 with a thickness of 15 MM with lugs. The upper end face of the mandrel 1 and the upper generatrix of the pin 2 are on the same plane, and the three points are roughly evenly distributed, so that the load-bearing plate 3 is horizontal and the load-bearing plate 3 It can carry the reaction force of the jack 5 to push out the bearing; the spacer 4, 20T universal jack 5 and the top bearing device 6 that transmit the force are placed in the center position on the bearing plate 3 from bottom to top, and the top bearing device 6 is supported on the holding plate 3. The axle box 8 is in contact with the bearing 9 through the short pin 7. The top bearing device 6 is a disc, and three squares are welded evenly around the circumference.

[0009] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com