An engine piston pin circlip assembly mechanism

An assembly mechanism and piston pin technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of operator injury, high rigidity, and inconvenient manual assembly, so as to protect assembly personnel, realize assembly automation, and improve Effect of circlip assembly speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In the following, referring to the drawings, through the description of the embodiments, the specific embodiments of the present invention such as the shape and structure of the various components involved, the mutual position and connection relationship between the various parts, the function and working principle of each part, etc. Detailed description:

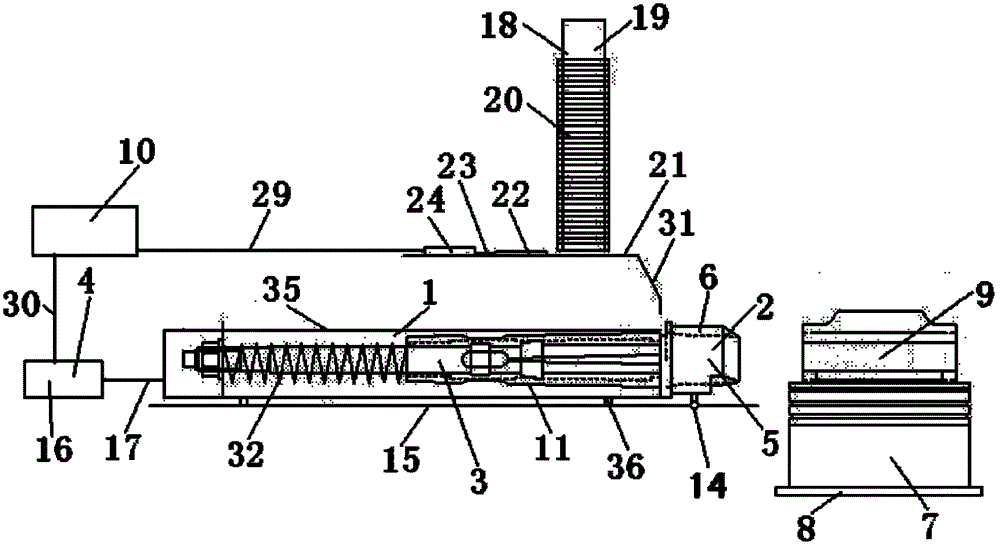

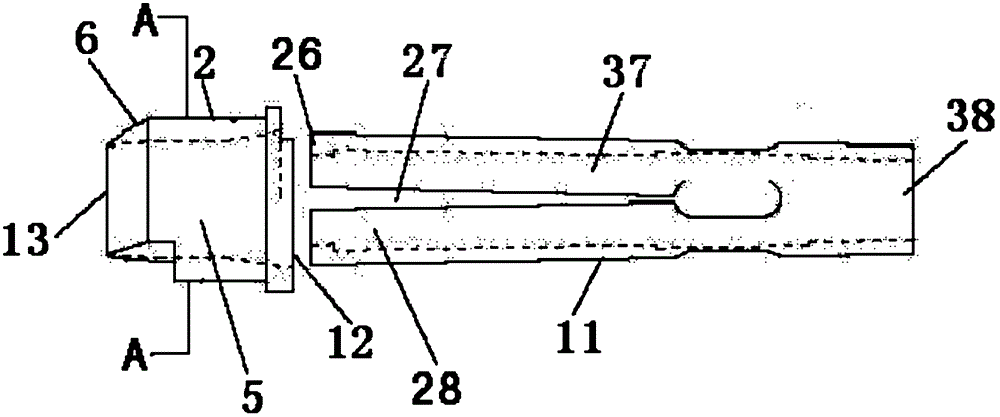

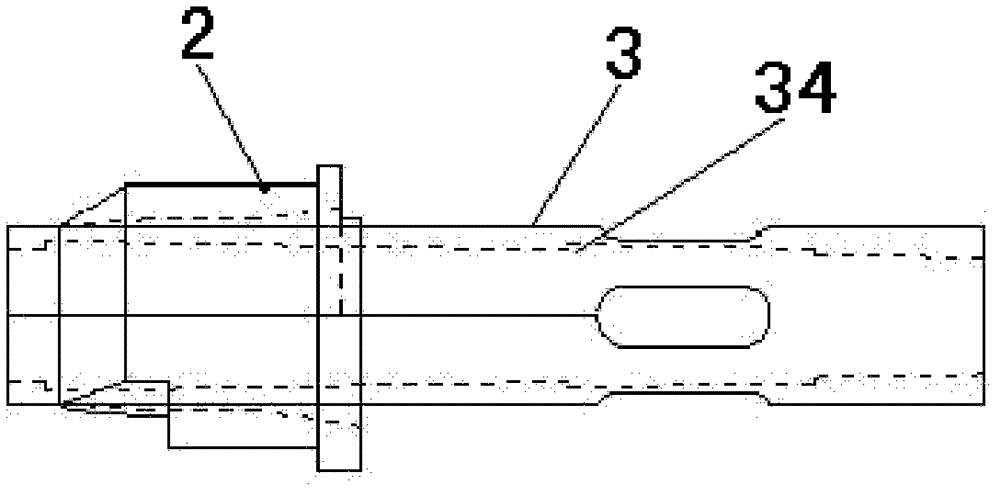

[0025] As attached figure 1 ——Attached Figure 5 As shown, the present invention is an engine piston pin circlip assembly mechanism. The engine piston pin circlip assembly mechanism includes a pressing device 1, a circlip pressure head 2, and a pressing guide post of the pressing device 1 3 is a rod-shaped structure. One end of the press-fitting guide column 3 is connected to a telescopic rod 4 that controls the expansion and contraction of the press-fitting guide column 3. The circlip pressure head 2 is set in a hollow cylindrical structure, and the middle is the pressure head cavity 5, and the circlip The upper end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com