Copper foil cutter

A cutting machine, copper foil technology, applied in metal processing and other directions, can solve the problems of difficult knife adjustment, short tool life, small cutting range, etc., to achieve convenient knife adjustment and maintenance, stable tool performance, and neat cutting face. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] This specific embodiment is an explanation of the present invention, not a limitation of the present invention. Those skilled in the art can make any amendments to this embodiment as required after reading this description, but as long as they are within the scope of the claims of the present invention, they are all subject to patent protection. legal protection.

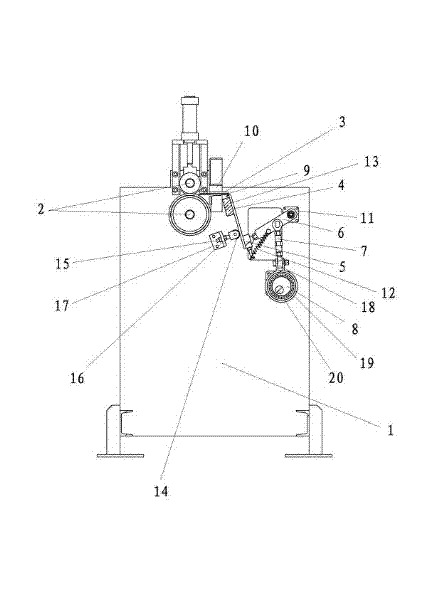

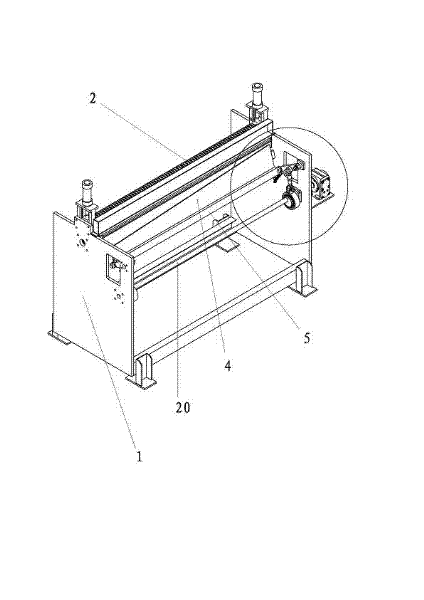

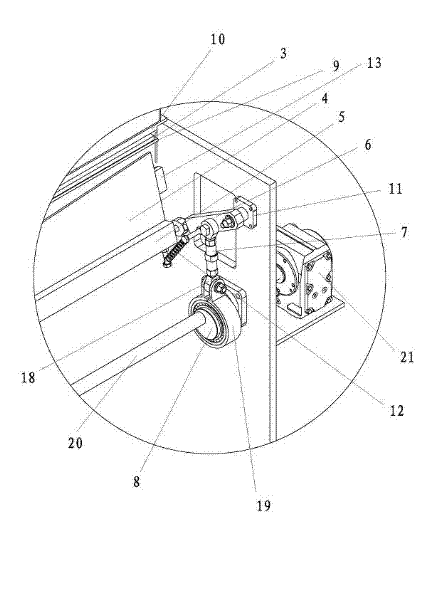

[0022] Such as Figure 1~3 As shown, a copper foil cutting machine includes a frame 1, a cutting mechanism and a copper foil pinch mechanism; the copper foil pinching mechanism includes a pair of pinch rollers 2; the cutting mechanism includes an upper knife 3 and a lower knife 4 And the action assembly; the action assembly includes the lower knife seat 5, the swing rod 6, the ejector rod 7, and the eccentric wheel 8; between the upper knife 3 and the lower knife 4, there is a copper foil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com