Tire bead structure capable of preventing translocation of tire bead for off-the-road tire with inner tube

A technology of construction machinery and bead, which is applied in the field of bead structure of construction machinery tires with inner tubes, which can solve the problems of strong interference loss of bead rings, affecting the convenience of tire loading and unloading, working efficiency of loading and unloading, and cost increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

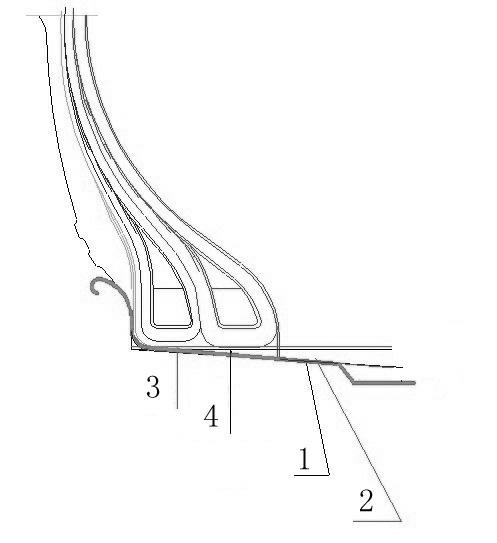

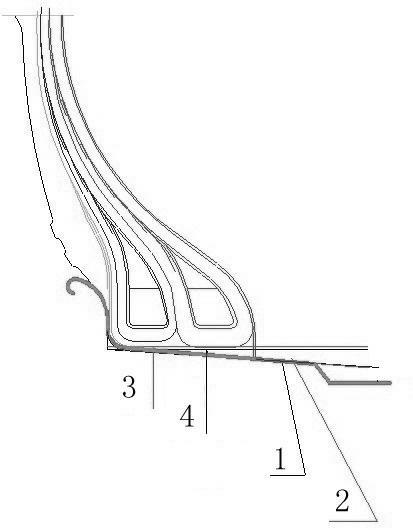

[0012] When designing the tire, the diameter Dr3 at the bottom of the bead is smaller than the nominal diameter D4 of the rim, and D-Dr is 1mm. The bottom surface angle of the bead is 5° smaller than the contact surface angle with the rim, and the value is 4°.

[0013] This kind of pneumatic tire can be assembled on the standard rim above 24in, and has a carcass with symmetrical bead parts. It can ensure a moderate close fit between the tire and the rim, so that the contact pressure of each part is reasonable and uniform. The bottom angle of the bead is 5° smaller than the angle of the contact surface with the rim, mainly to facilitate the bead on one side of the tire to be easily placed into the rim, and the removed rim flange and one side of the bead seat are pressed into the bead on the other side, together Complete tire and rim installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com