Variable flat plate type bionic leading edge flap device

A leading edge flap, flat-plate technology, applied in transportation and packaging, aircraft parts, aircraft control, etc., can solve problems such as processing difficulties, increase resistance, etc., to prevent flight safety accidents, improve lift coefficient, and improve maneuverability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

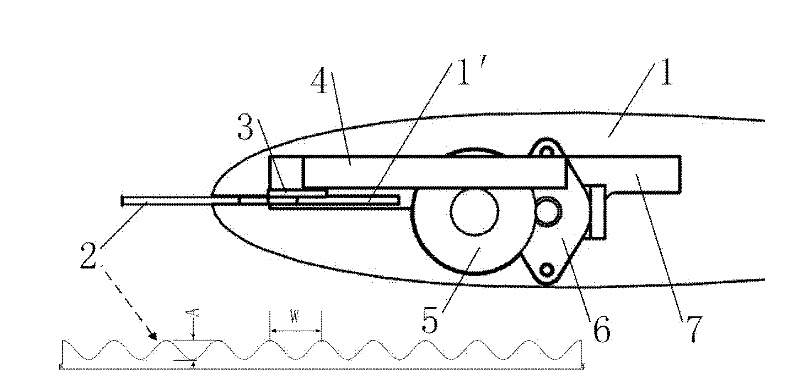

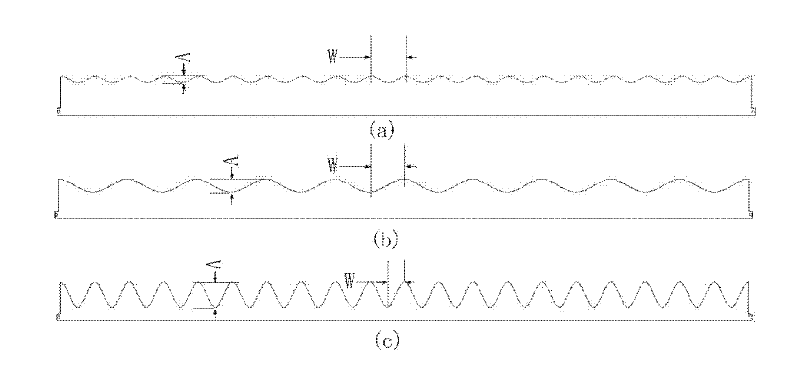

[0027] Such as figure 1 As shown, a variable flat-plate bionic leading edge flap device of the present invention is composed of three parts: the bionic leading edge flap (2), the leading edge flap storage chamber (1') and the telescopic actuating mechanism. The bionic leading edge flap (2) is placed in the leading edge flap storage cavity (1') at the leading edge of the wing, and is connected with the telescopic actuating mechanism. The telescopic actuating mechanism is driven by a first-stage reduction gear (5) rack (4) mechanism driven by a micro-stepping motor (6), which enables the bionic leading edge flap (2) to be freely extended and recovered.

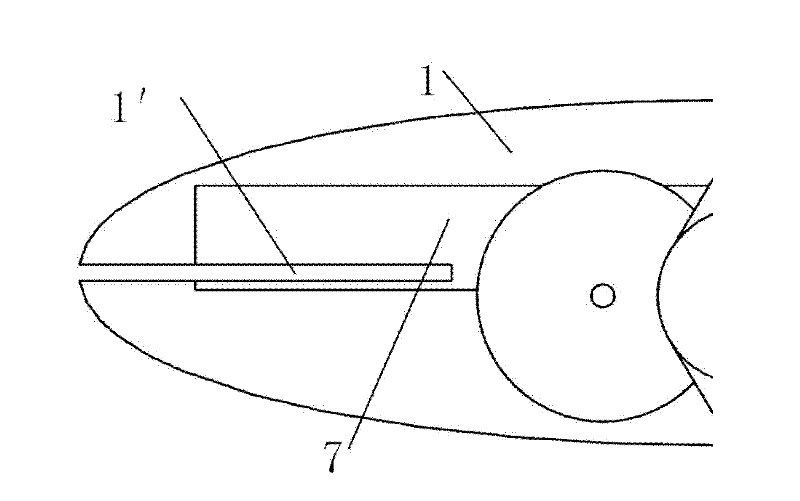

[0028] Such as figure 2 As shown, it is a partially enlarged schematic diagram of the leading edge flap storage cavity (1'), which is a rectangular opening along the chord li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com