Novel parafoil and steering and control method thereof

A control method and parafoil technology, applied to parachutes, aircraft parts, transportation and packaging, etc., can solve the problems of high weight cost, limited control ability, and low control accuracy, and achieve weight reduction, small control force, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

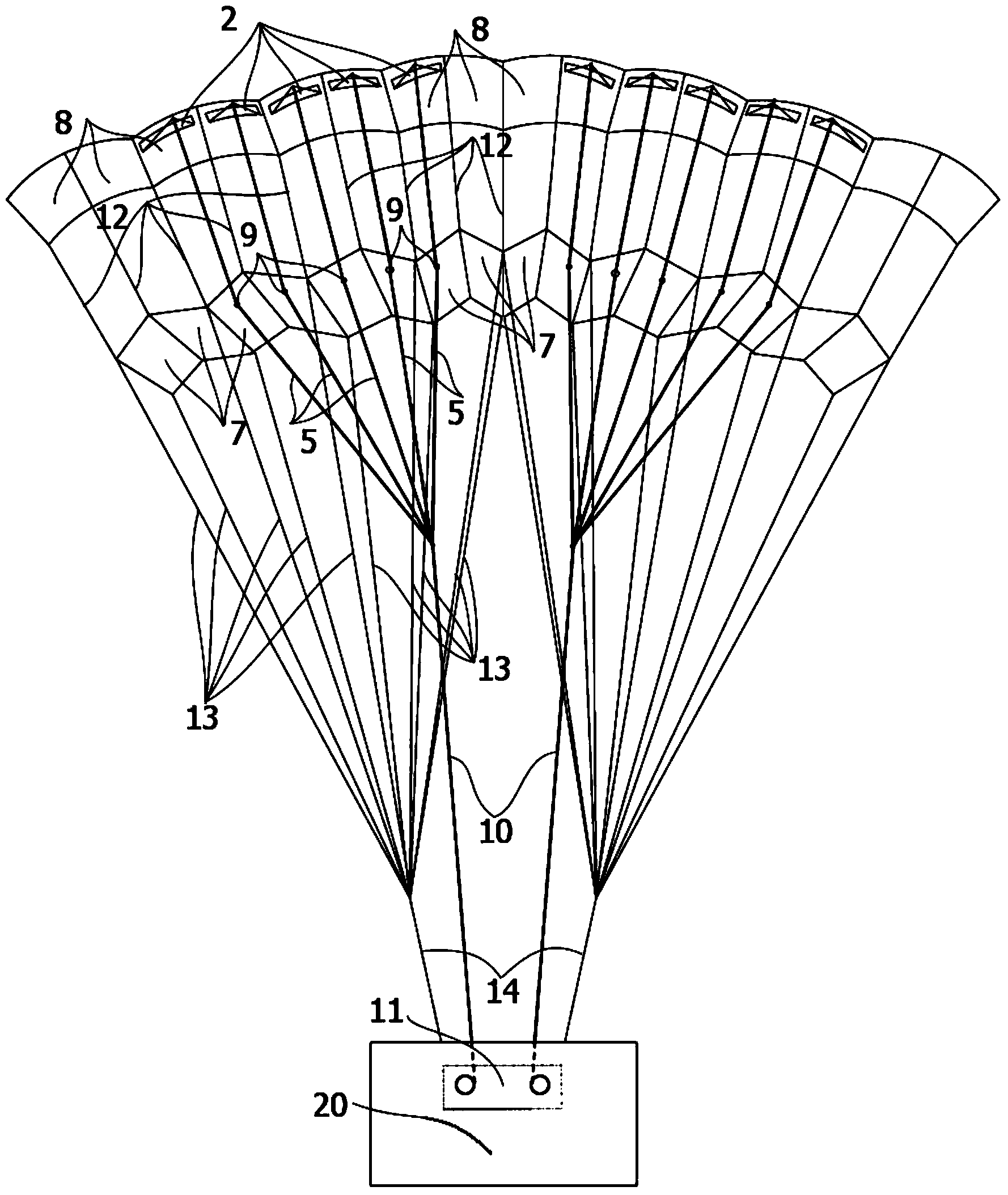

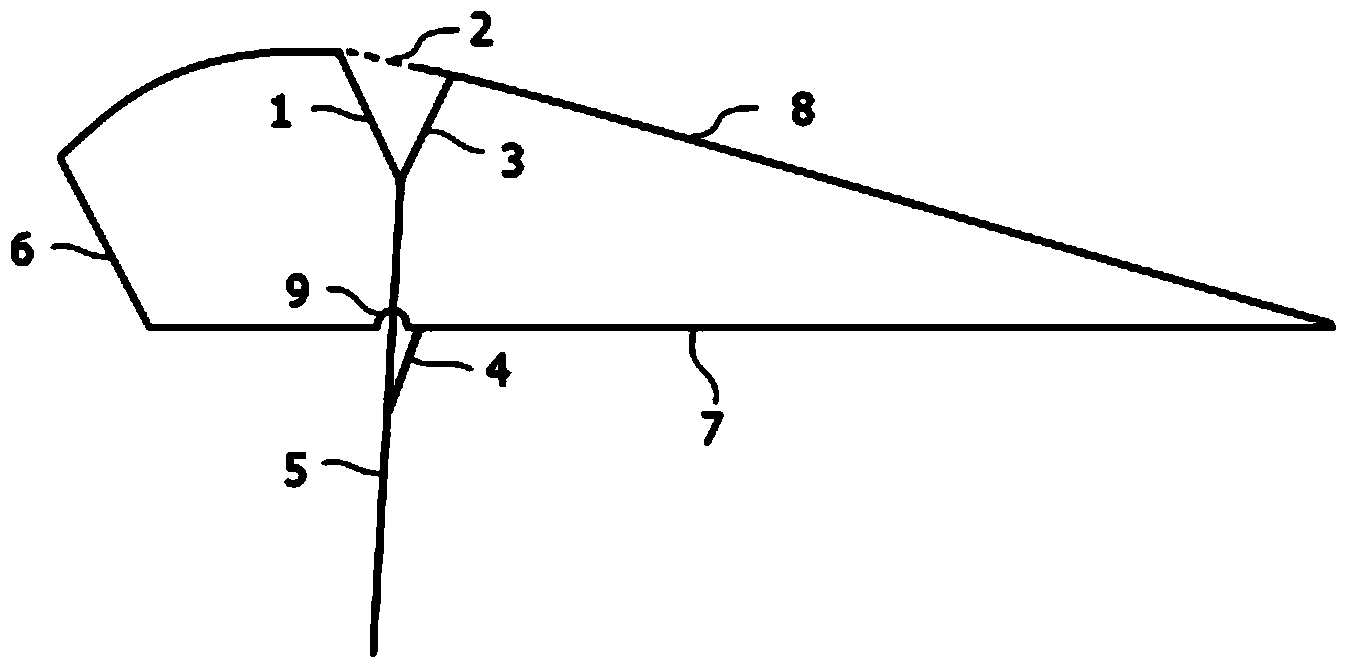

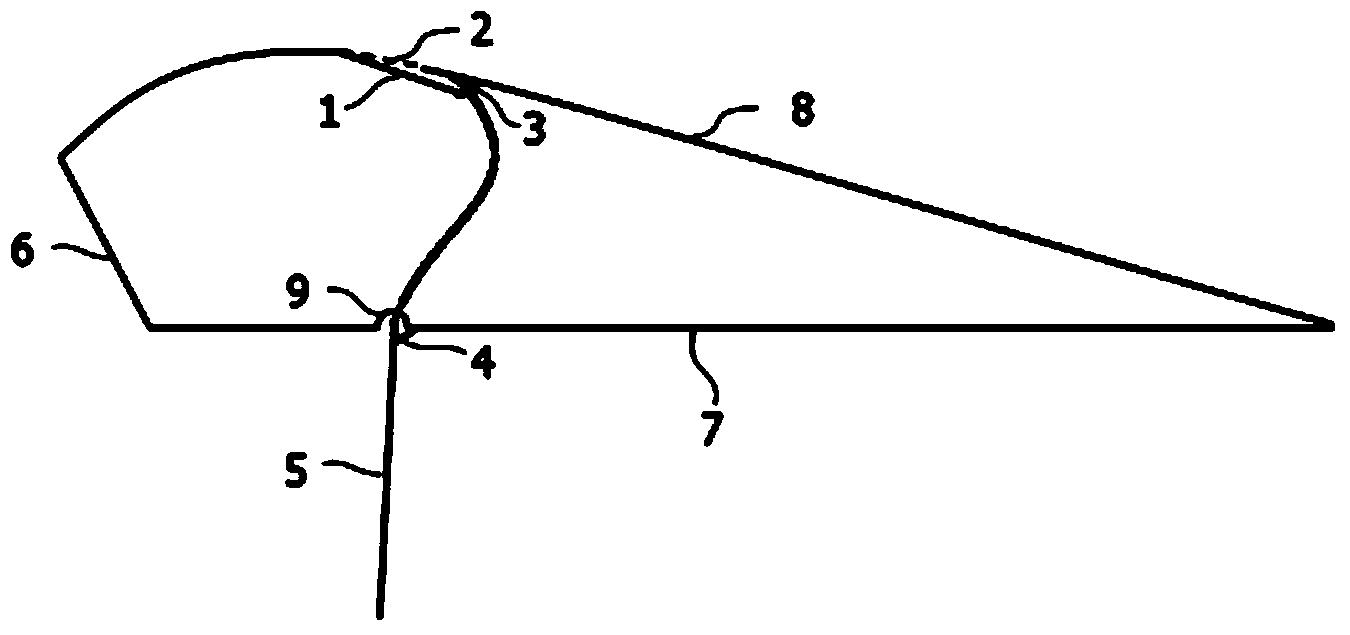

[0028] refer to Figure 1 to Figure 5 As shown, the novel stamping parafoil described in the present invention comprises an upper airfoil 8, a lower airfoil 7, a plurality of ribs 12, two groups of parachute ropes 13, two groups of control ropes 5, two groups of slings 14, two A control belt 10, the trailing edge of the upper airfoil 8 is connected to the trailing edge of the lower airfoil 7, the ribs 12 are parallel to each other, and the two ends of each rib 12 are connected to the upper airfoil 8 and the lower airfoil respectively. 7 connection, every two ribs 12 and the space between the upper airfoil 8 and the lower airfoil 7 form an air chamber with a leading edge opening 6; a number of diversion holes 2 are symmetrically arranged on both sides of the upper airfoil 8, A deflector 1 is arranged on the inner side of the upper airfoil 8 correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com