General purpose gantry crane

A gantry crane and gantry technology, applied in the direction of hoisting equipment braking devices, load hanging components, bottom support structures, etc., can solve the problem of increased span value of cranes, inability of wheels to fall on rails, and inability to realize heavy load steering, etc. problem, to achieve the effect of simple and simple force, ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with embodiment (accompanying drawing)

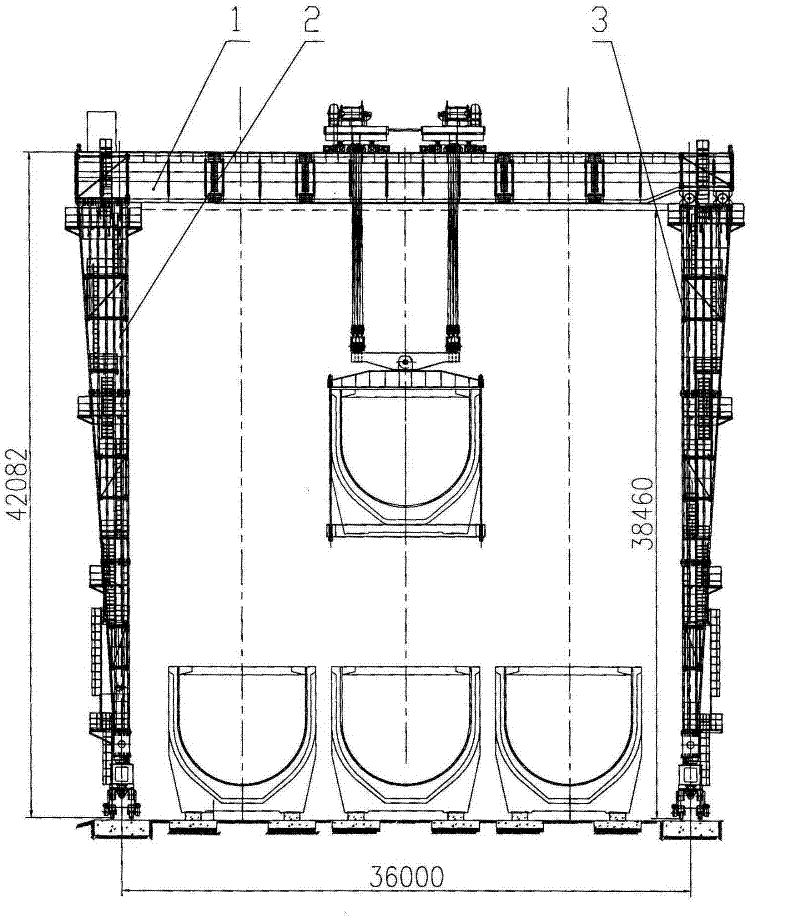

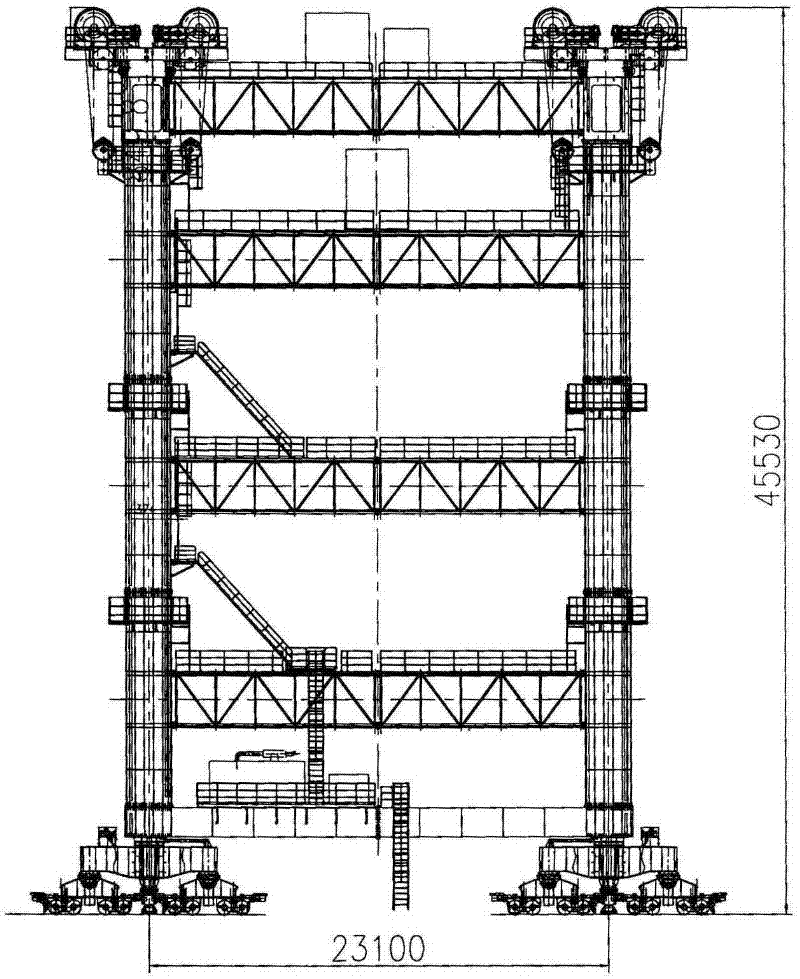

[0025] Such as figure 1 , 2 shown. The general-purpose gantry crane of the present invention comprises a gantry girder 1, and supporting legs positioned at both sides of the gantry main girder, one side of the described two side supporting legs is a rigid supporting leg 2, and the other side supporting leg Using semi-rigid legs 3, the rigid legs 2 are consolidated with the main beam 1 of the mast frame through connecting bolts, and the upper ends of the semi-rigid legs 3 are respectively welded to the main beam 1 of the mast frame and the semi-rigid legs The mutually matched supporting leg hinge seats on the 3 are combined with the main girder 1 of the main frame in a hinged manner.

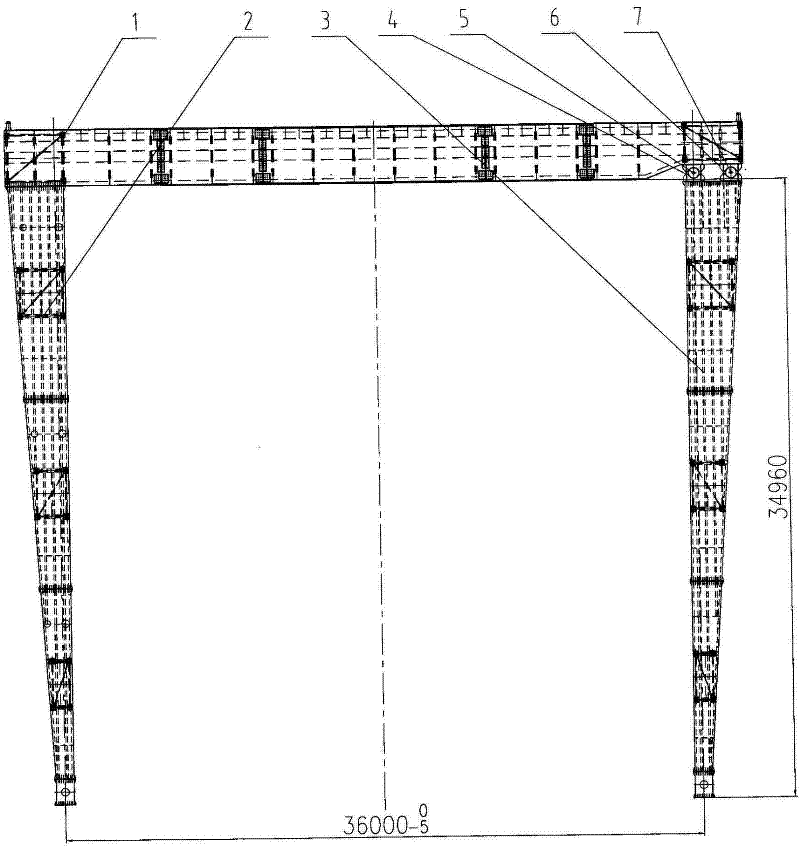

[0026] Such as image 3 , 4 , 5, 6, and 7, the leg hinge seat described in the present invention includes: the leg inner hinge composed of two groups of front and rear inner u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com