Extra large-caliber fire fighting hose and preparation method thereof

A technology for fire hoses and super-large calibers, which is applied to mechanical equipment, hoses, pipes, etc., and can solve problems such as unbearable fire hoses, high water pressure, use range and field restrictions, etc., to achieve fast water output and large water output , laying the effect quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

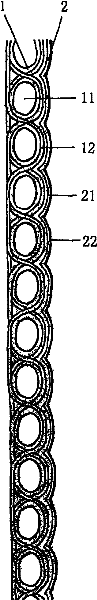

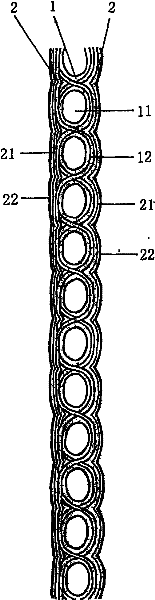

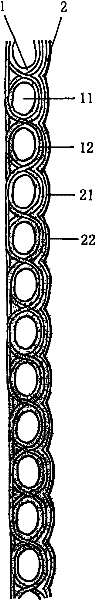

[0016] Such as figure 1 and figure 2 As shown, the super-large diameter fire hose of the present invention is composed of a blank 1 and a composite layer 2, the blank 1 is tubular, the composite layer 2 is arranged inside the blank 1, and the blank 1 is arranged inside the blank 1. The strip blank 1 is made of fiber weaving, and the composite layer 2 is formed by dual-mode co-extrusion of a thin-walled polyurethane adhesive layer 21 and a polyurethane waterproof layer 22. The thickness of the thin-walled polyurethane adhesive layer 21 and the polyurethane waterproof layer 22 is The ratio is 1:2 to 1:3.

[0017] Further, the strip blank 1 is braided by warp threads 12 and weft threads 11 .

[0018] Further, the warp thread 12 is formed by plying polyester filaments or twisting polyester yarns.

[0019] Further, the weft 11 is composed of polyester filaments and jet filaments twisted together.

[0020] Further, a layer of composite layer 2 is also provided on the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com