Split-type roll gap measuring instrument

A measuring instrument and separate technology, applied in the field of split roll gap measuring instruments, can solve the problems of not being able to reflect the working conditions of the continuous casting machine in real time, taking a long time, and high labor intensity, and achieving compact structure, high reliability, and installation. Maintenance simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

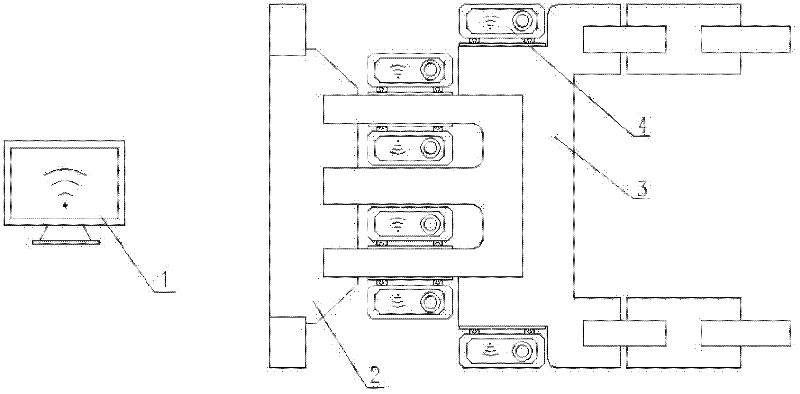

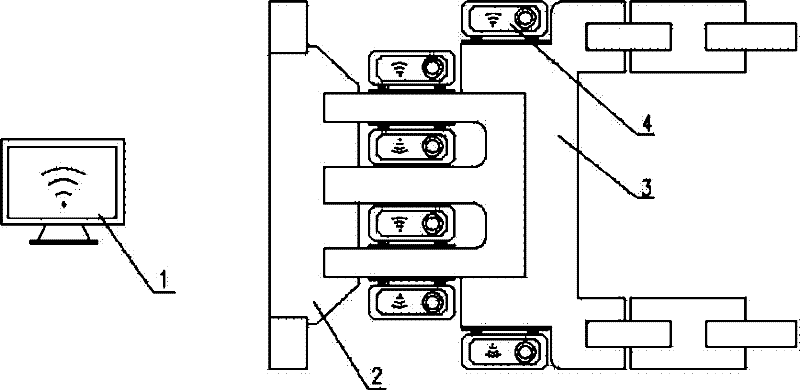

[0014] see figure 1 , a split-type roll gap measuring instrument, including two or more on-site detection units 4 and a data processing station 1, each on-site detection unit 4 transmits data to the data processing station 1 through a wireless network, and on-site detection The unit 4 is installed on the dummy chain 3, and the on-site detection unit 4 and the data processing station 1 exchange data through wireless transmission, which can realize the remote control and monitoring of the working status of each on-site detection unit 4 by the data processing station 1, and the on-site detection unit 4 Self-contained power supply without external power supply.

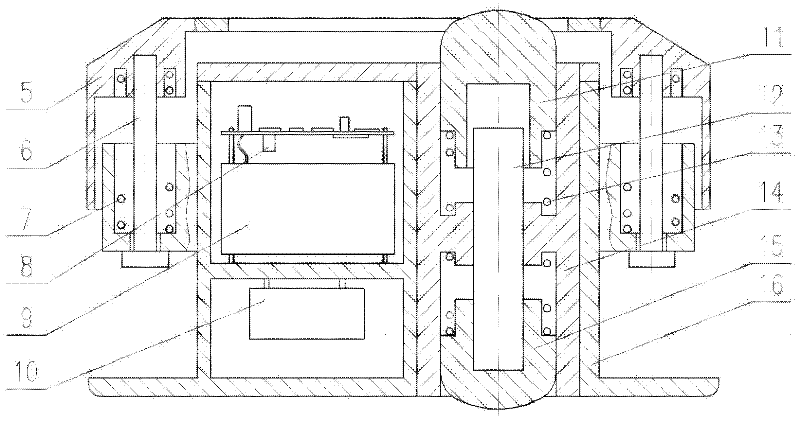

[0015] The on-site detection unit 4 includes a control module 8, the first signal end of the control module 8 is connected with the roll gap sensor 12, the second signal end of the control module 8 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com