inspection vehicle for inspecting roughly cylindrical objects

A vehicle, cylindrical technology, applied in the direction of material analysis, engine function, instrument, etc. using sonic/ultrasonic/infrasonic waves, can solve problems such as long preparation time, and achieve the effect of increasing flexibility, avoiding damage, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

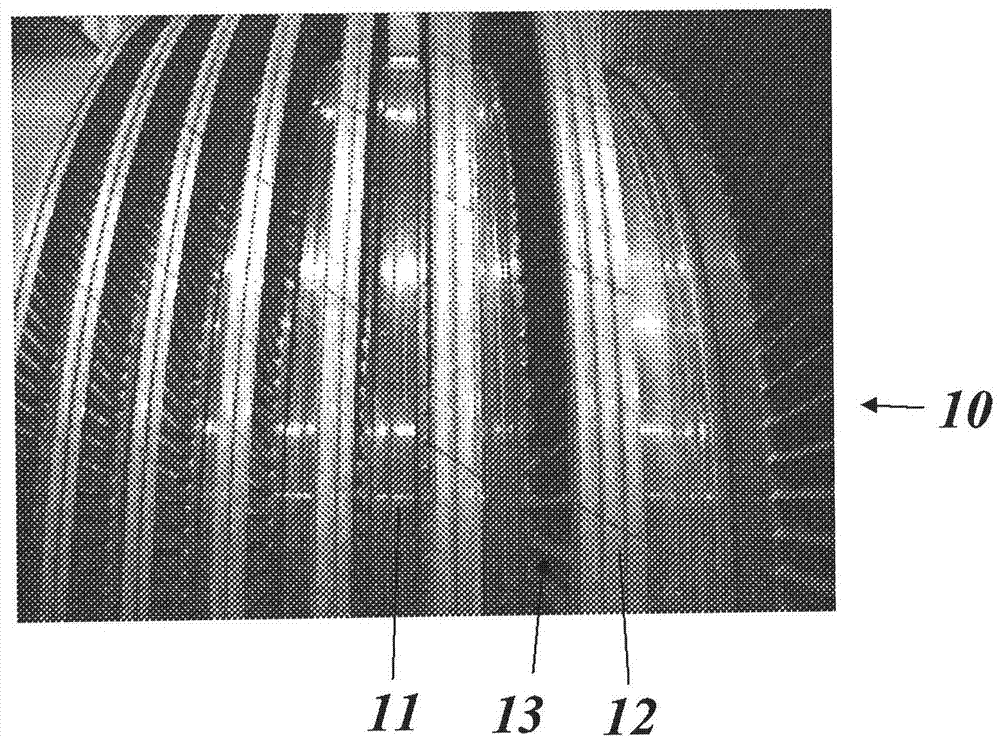

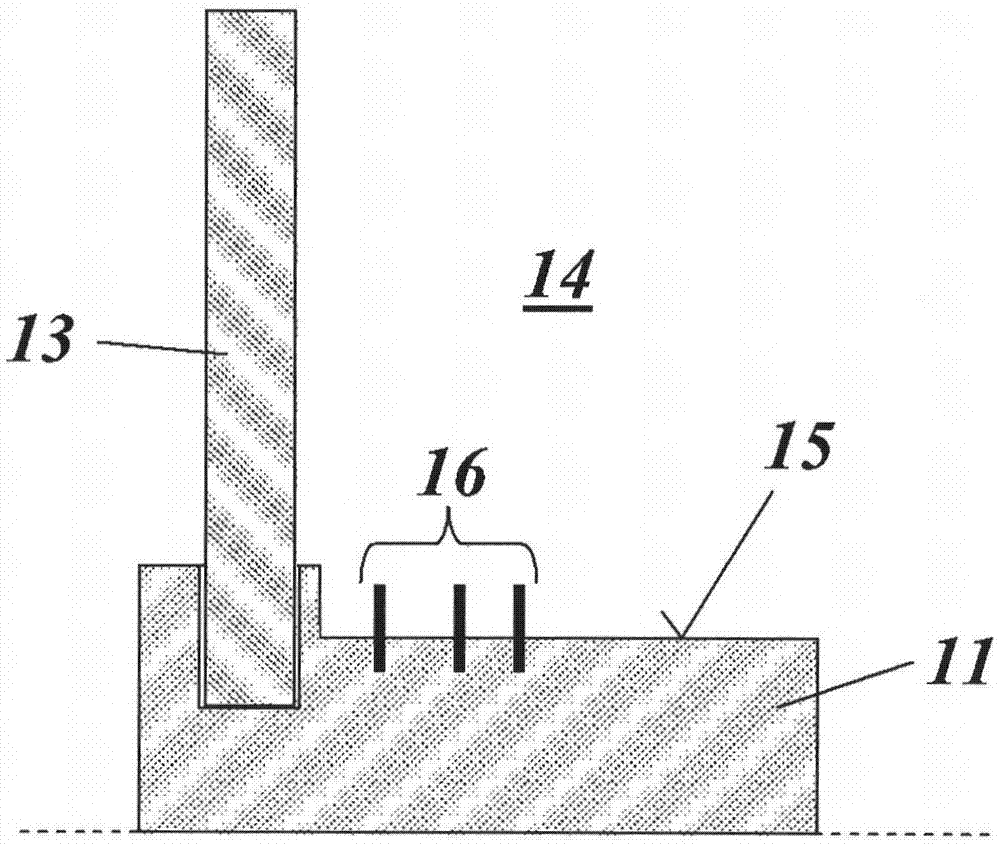

[0062] figure 1 A photograph of a rotor 10 of a steam turbine is shown with a plurality of blade rows 12 with rotor blades 13 arranged around a central rotor shaft 11 . The rotor blades 13 are held with their blade bases in annularly circumferential blade grooves and form a circumferential blade gap 14 therebetween, one of which is in the figure 2 is partially shown in cross-section. figure 2 The vane gap 14 includes rotor vanes 13 in surrounding vane grooves in the rotor shaft 11 and laterally bounded by the rotor vanes 13, which can be used as a lateral reference when the vane gap 14 is passed by a vehicle noodle.

[0063] exist figure 2 Illustratively three sealing strips 16 are shown side by side in the outer surface 15 of the rotor shaft 11 , which are inserted into the outer surface 15 but project radially by a piece from the outer surface 15 . It is especially an obstacle of the type that makes it impossible to use conventional vehicles.

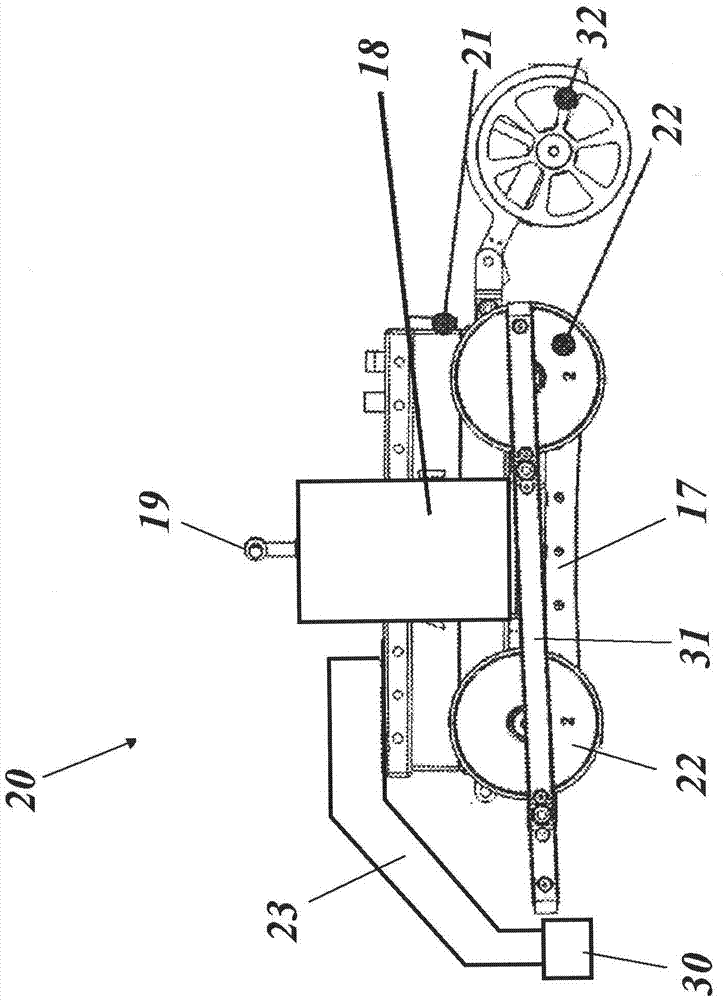

[0064] exist image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com