Intelligent detection sensor for spray nozzle blockage of full-automatic glue sprayer

A technology of intelligent detection and glue spraying machine, which is applied in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum degree for liquid tightness measurement. It can solve problems such as nozzle blockage of automatic glue spraying machine and reduce industrial economy The effect of loss, avoidance of missed spray, and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

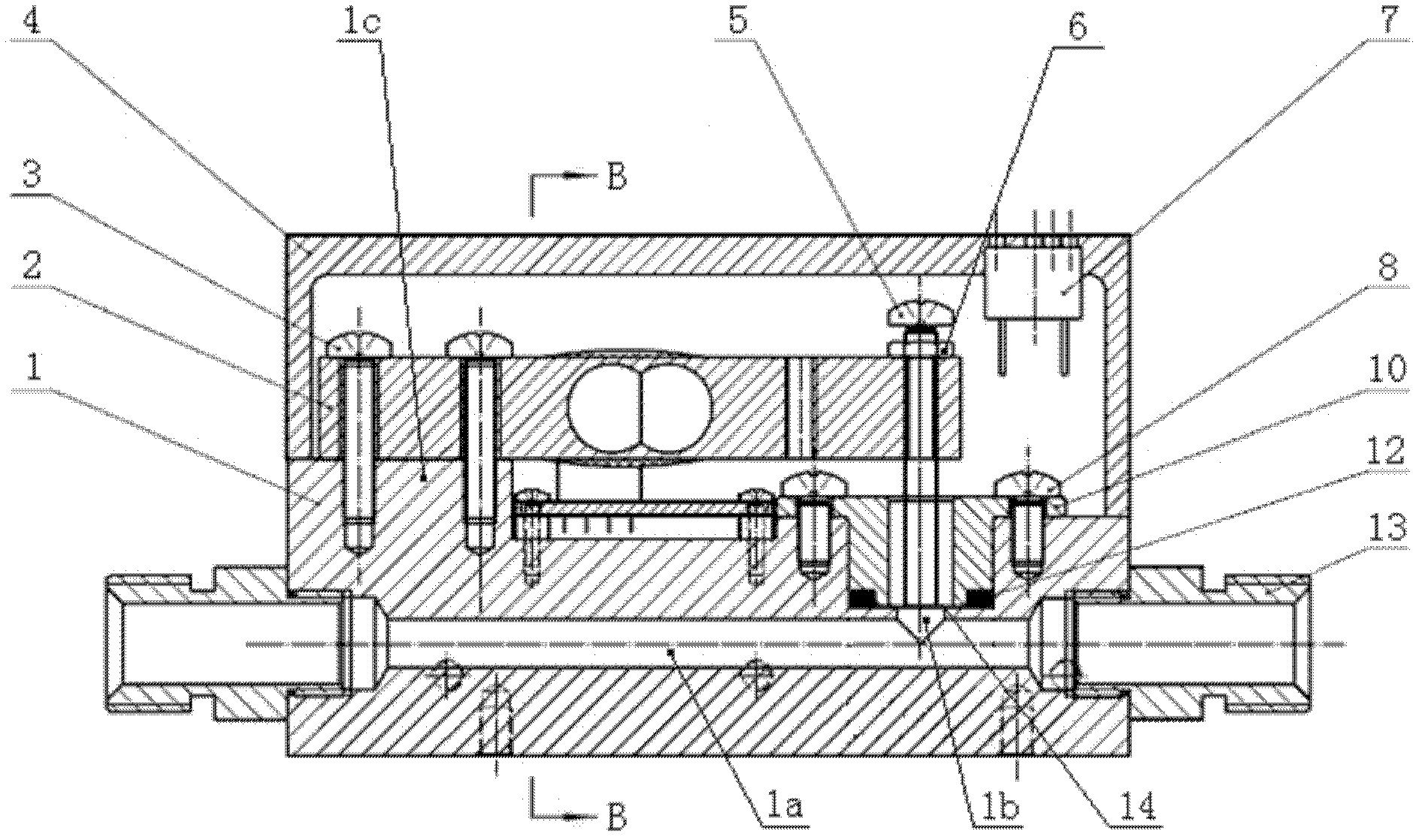

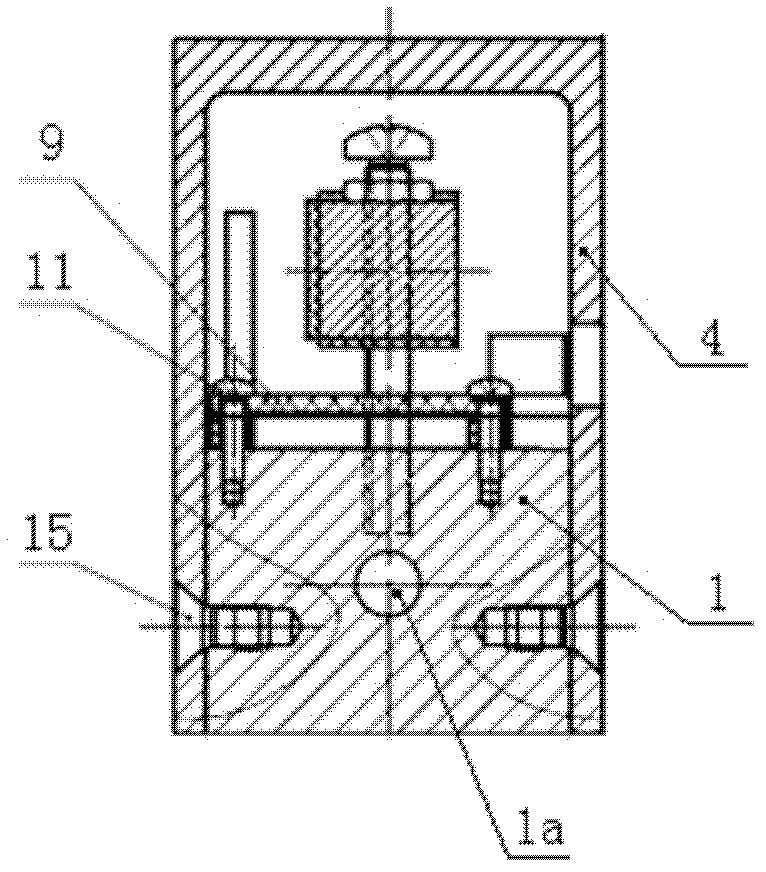

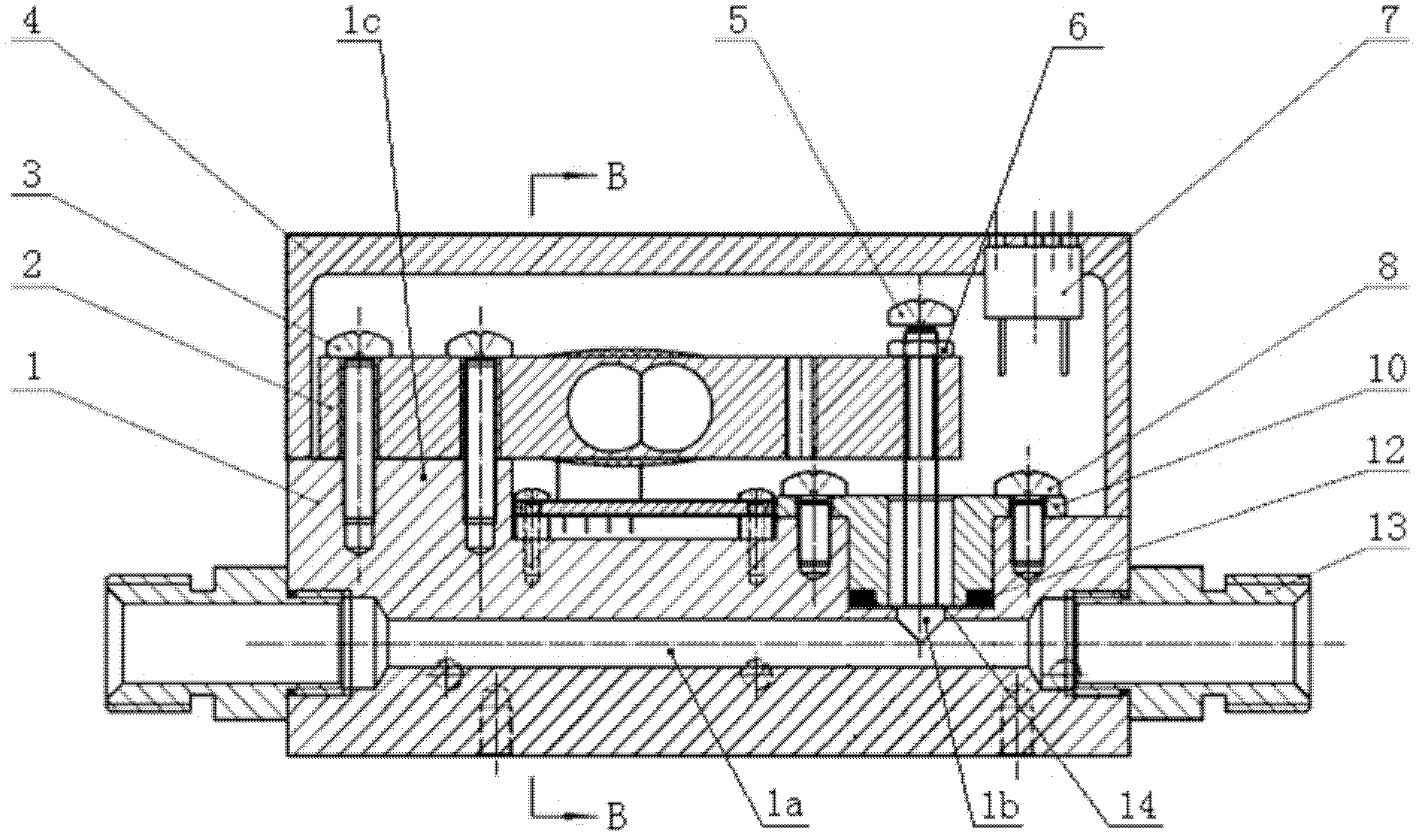

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0015] As shown in the figure: the intelligent detection sensor for nozzle blockage of the automatic glue spraying machine is mainly composed of a detection body 1, a strain sensor 2, a cross recessed pan head screw 3, a body cover 4, a detection screw 5, a nut 6, an alarm 7, Cross recessed pan head screw 8, circuit board 9, flange 10, cross recessed pan head screw 11, sealing gasket 12, transition pipe joint 13 and elastic steel sheet 14 and other components.

[0016] Such as figure 1 , figure 2 As shown, the detection body 1 is provided with a paint channel 1a with a diameter of Φ8mm. The two ends of the paint channel 1a are threadedly connected with a transition pipe joint 13. The transition pipe joint 13 at one end of the paint channel 1a is used to connect the spraying pipeline. The paint channel 1a The transition pipe joint 13 at the other end is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com