Integrally-containing type torque sensor motor

A torque sensor and accommodating technology, applied in the structural field of bicycle electric power sensor motors, can solve the problems of reducing the reliability of sensing signals, limiting the use range, increasing production costs, etc., to achieve intensive production, obvious magnetic induction effect, Solve the effect of occupying space

Inactive Publication Date: 2012-04-11

WUXI SHANGGE IND DESIGN

View PDF8 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] In the field of bicycle electric power-assisted sensors, Chinese invention patent application 201110125438.9 discloses a "structure of electric power-assisted sensors that cooperate with bicycle rear forks". A circuit board equipped with a Hall element is arranged, and a sensor assembly on the rear axle that passes through the long slot hole at the bottom of the groove and is movable is accommodated in the groove, and a permanent magnet arranged on the sensor assembly is connected to the The Hall element on the circuit board is magnetically coupled; because the rear shaft is limited to move in the long slot hole at the bottom of the groove, when the rear shaft is used to move, the gap between the permanent magnet relatively fixed to the rear shaft and the Hall element The magnetic induction changes,

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

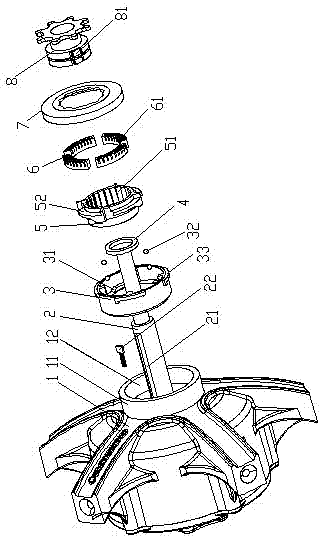

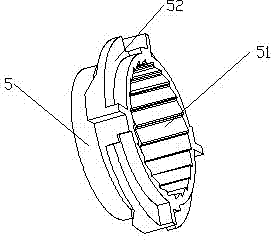

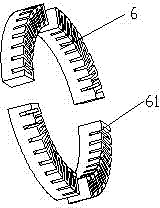

The invention provides an integrally-containing type torque sensor motor. A motor shell and a motor shaft are provided with a hollow containing cavity which is composed of annular bulges in a coaxial direction; a fixed sliding guide ring is contained and arranged in the hollow containing cavity and the fixed sliding guide ring is dynamically matched with a floating ratchet induction coil subassembly which is equipped with magnetic steel; the floating ratchet induction coil subassembly comprises a ratchet induction coil and ratchets of a flywheel are matched with gear grooves which are annularly distributed in the ratchet induction coil; the motor shaft is provided with a Hall element and the magnetic steel of the floating ratchet induction coil subassembly is matched with the Hall elementin a magnetic induction manner, so that an electric signal is output to control stress-applied rotation of vehicles. According to the invention, all parts of a Hall sensor are skillfully arranged on the motor shell so that the space occupation problem caused by function settings is solved; the integrally-containing type torque sensor motor has the advantages of high standardization degree, wide application range, obvious magnetic induction effects, easiness of intensive production, low carbon, environmental friendliness, and convenience for installation and maintenance.

Description

technical field [0001] [0002] The invention relates to the field of vehicle electric power-assisted transmission, in particular to a structure of a bicycle electric power-assisted sensor motor. [0003] Background technique [0004] In the field of bicycle electric power-assisted sensors, Chinese invention patent application 201110125438.9 discloses a "structure of electric power-assisted sensors that cooperate with bicycle rear forks". A circuit board equipped with a Hall element is arranged, and a sensor assembly on the rear axle that passes through the long slot hole at the bottom of the groove and is movable is accommodated in the groove, and a permanent magnet arranged on the sensor assembly is connected to the The Hall element on the circuit board is magnetically coupled; because the rear shaft is limited to move in the long slot hole at the bottom of the groove, when the rear shaft is used to move, the gap between the permanent magnet relatively fixed to the rear ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02K11/00H02K7/116H02K29/08

CPCH02K1/185H02K11/215H02K11/24

Inventor 王欢

Owner WUXI SHANGGE IND DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com