Adhesive article comprising an acrylic foam layer

An adhesive and foam layer technology, applied in film/sheet adhesives, adhesive types, ester copolymer adhesives, etc., can solve problems such as environmental management and processing costs affecting product formulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

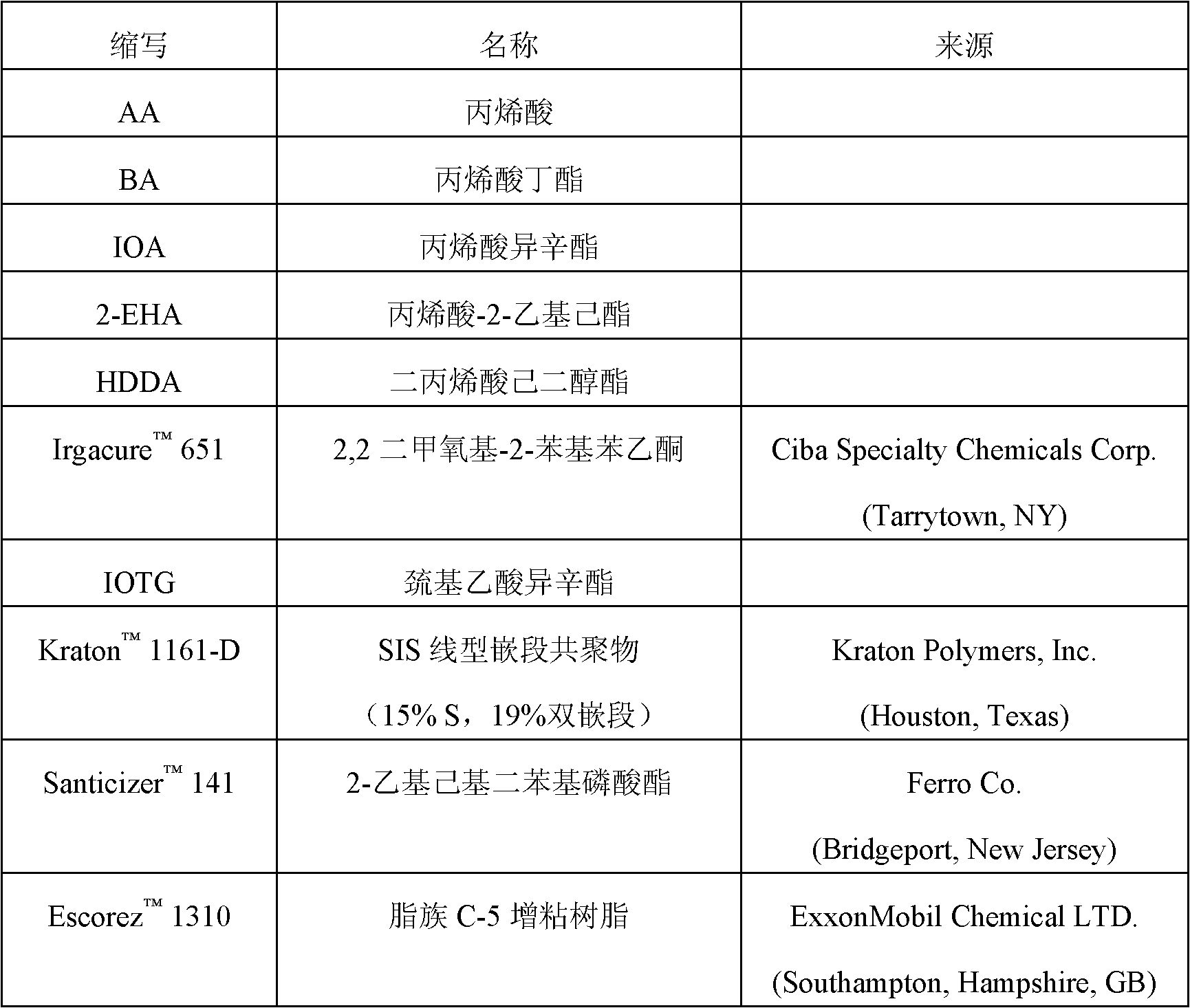

[0014] The specific embodiments of the present invention are summarized as follows:

[0015] 1. An adhesive article comprising: a foam layer having first and second major sides; a pressure sensitive adhesive layer attached to at least one of the major sides of the foam layer, the pressure sensitive adhesive The layer comprises cross-linked rubber, wherein said foam layer comprises an acrylic polymer obtainable by polymerizing a polymerizable composition comprising one or more compounds having an average of 3 to 14 carbon atoms in the alkyl group Alkyl acrylate, one or more polar monomers and one or more polyfunctional monomers having at least two radically polymerizable groups.

[0016] 2. The adhesive article of embodiment 1, wherein the polymerizable composition comprises 83 to 97% by weight of the alkyl acrylate, 3 to 16% by weight of the polar monomer and 0.01 to 1% by weight of the polyfunctional monomer.

[0017] 3. The adhesive article of embodiment 1 or 2, wherein th...

example

[0116] testing method :

[0117] Dynamic Shear Test :

[0118] A modified version of ISO4587:2003 is adopted.

[0119] The strip to be tested is applied with its specific side to the painted steel substrate. On the opposite side of the tape, aluminum coupons (50 mm x 25 mm x 1 mm) were applied.

[0120] The adhesive tape area applied horizontally was 1.27 cm x 2.54 cm.

[0121] Painted steel panels used in this test method were obtained from the suppliers mentioned in a separate section below. Basic instructions on said paints are also provided in a separate section below.

[0122] Paint A and Paint B were cleaned by wiping with a tissue soaked in n-heptane. Paint C was cleaned by wiping with a tissue soaked in a 1:1 volume mixture of water and isopropanol. For testing, the painted steel sheet substrates were cut into test pieces (50 mm x 30 mm x 1 mm).

[0123] Subject the aluminum coupons to Scotchbrite TM no.7447 TM Light abrasiveness of a scrub pad (available ...

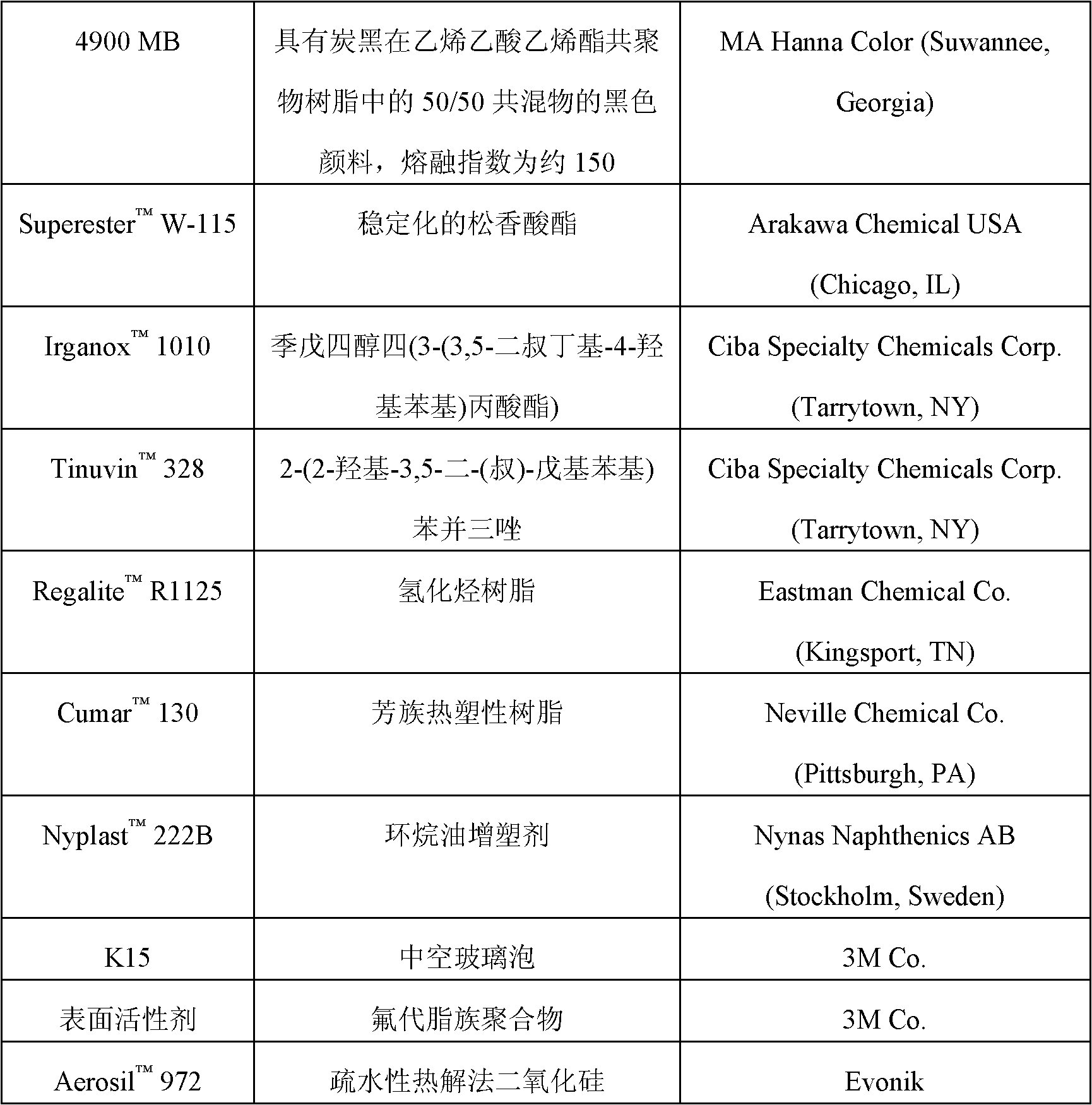

example A

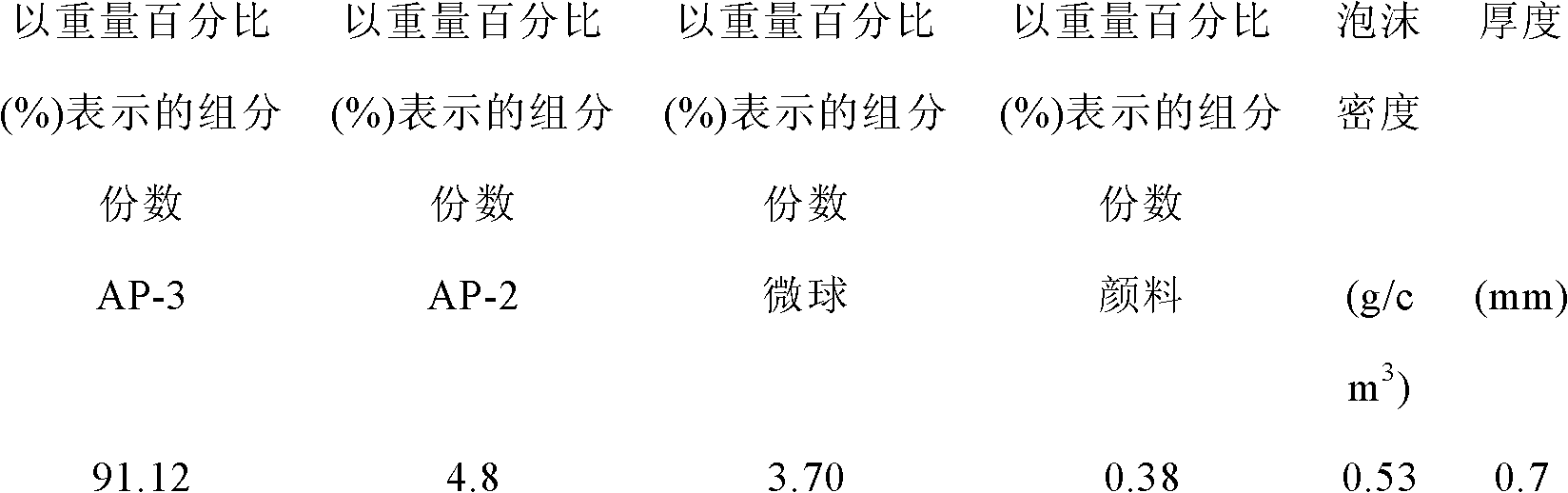

[0160] The foam core (FC-1) having the composition shown in Table 3 was compounded according to the following procedure. Black pigmented EVA (4900 cmB) was dry fed into the first zone of a 90 mm co-rotating twin-screw extruder ("core extruder") (available from Berstorff, Hannover, Germany). Using a roll-fed extruder (available from Berstorff), both the acrylics AP-2 and AP-3 were heated and fed into the second zone of the core extruder. DUALITE U010-185D expandable microspheres (expandable microspheres having a shell composition comprising acrylonitrile and methacrylonitrile and an isopentane core, available from Henkel Corporation (Gulph Mills, Pennsylvania)) were fed into the core extrusion. Out of the Ninth District of the plane.

[0161] Table 3: Foam Core Composition FC-1 and Properties

[0162]

[0163]Three-layer coextruded tape samples were prepared by coextruding a first skin adhesive layer, a foamed core layer as an intermediate layer, and a second skin adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com