Telescopic plate pressing device

A telescopic and pressing plate technology, which is applied in the field of pressing plate devices, can solve the problems of increasing processing time and increasing process pressure points, and achieve the effects of saving processing time, fast clamping, and convenient pressing and loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

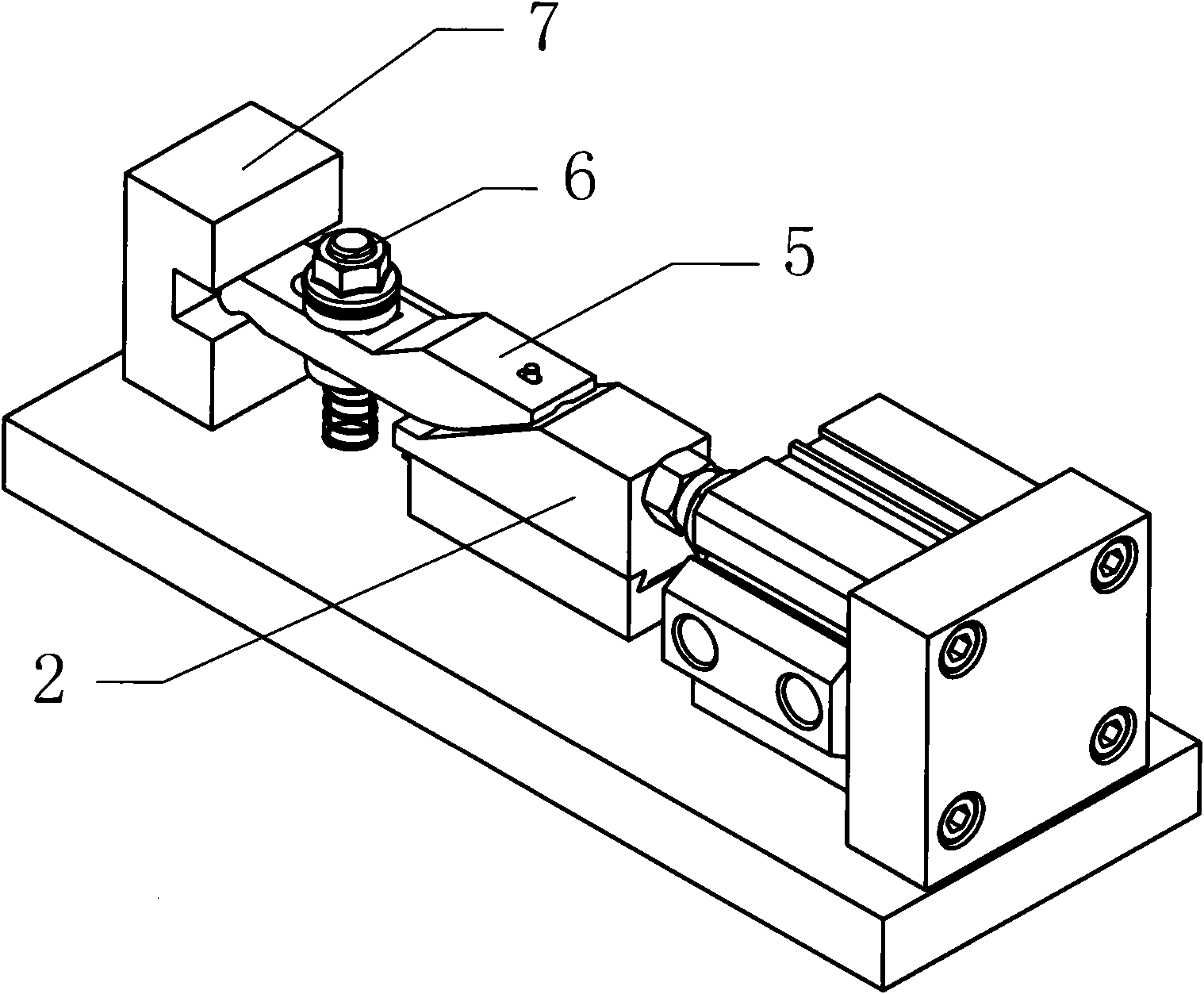

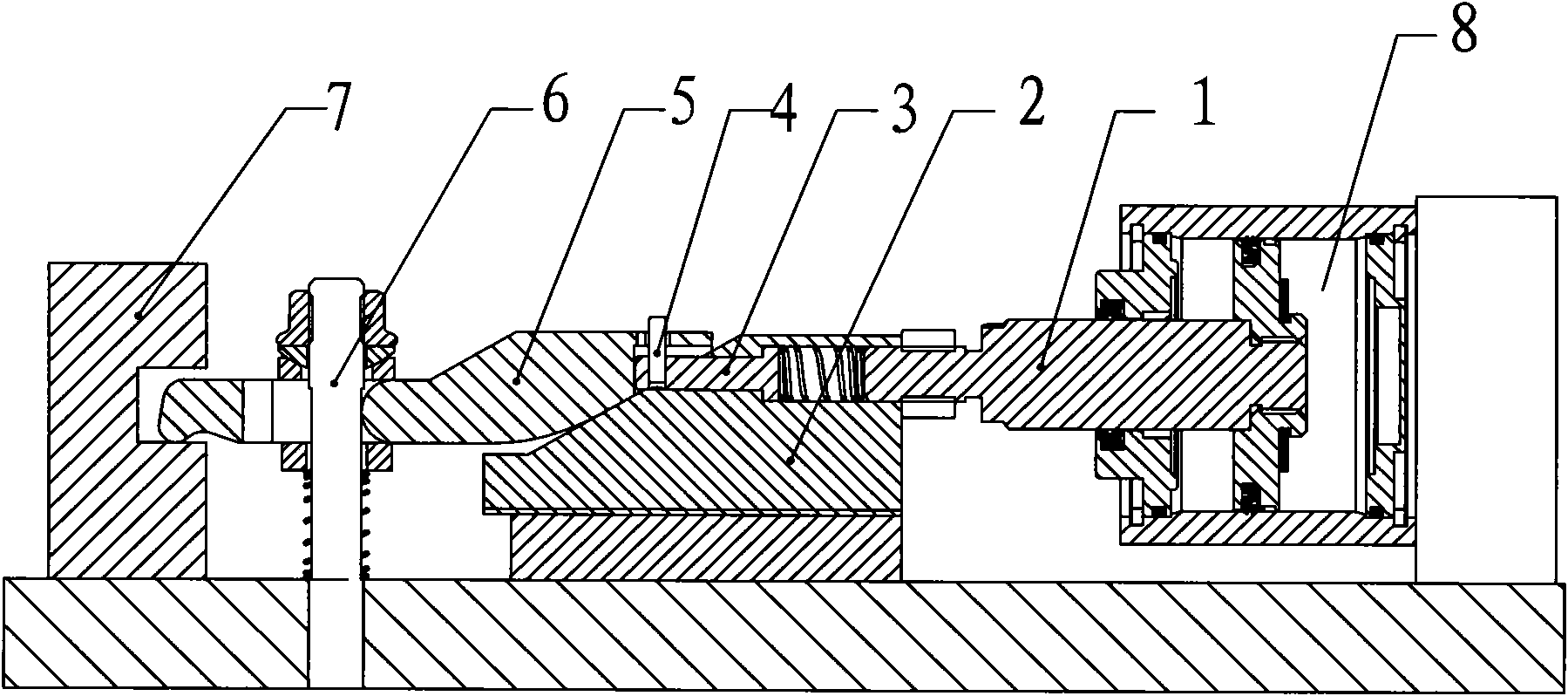

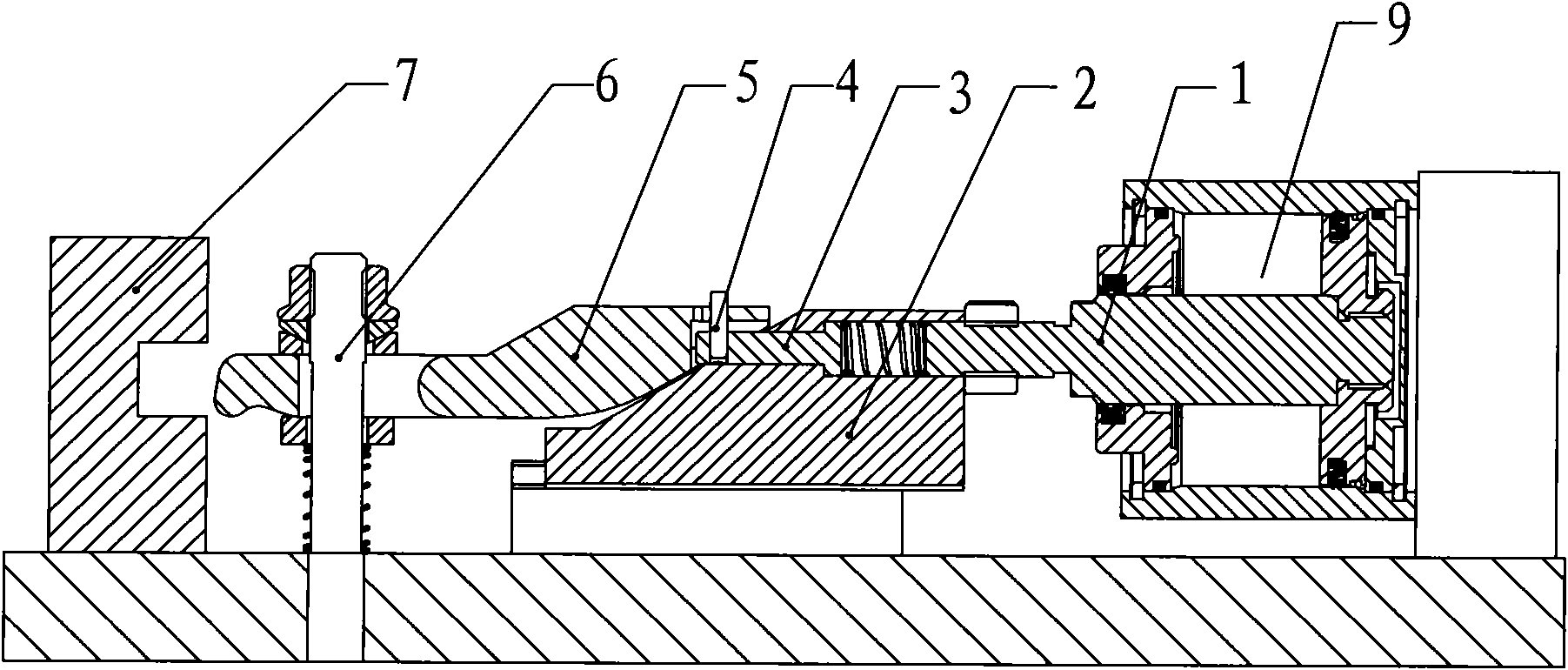

[0020] like Figures 1 to 3 The shown telescopic pressing plate device includes a main body of the pressing plate device. The special feature is that a cylinder is provided at one end of the main body of the pressing plate device, and the rear end of the piston 1 is arranged in the cylinder, and the rear end of the piston 1 is arranged in the cylinder. The cylinder is divided into two working chambers, namely A chamber 8 and B chamber 9. At the same time, the head of the piston 1 is connected to the push pin 3 through an elastic member, and the head of the piston 1 and the outer cover of the push pin 3 are provided with a slider 2 . In addition, the slider 2 is connected to one end of the pressing plate 5 through the fixing pin 4, and the other end of the pressing plate 5 is the working end, and the working end has a hollow slot. Furthermore, the hollow groove is provided with a screw 6, and the bottom of the screw 6 is fixed on the main body of the pressing plate device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com