Floating guide device for use on long-travel hydraulic press

A floating guide, hydraulic press technology, applied in the field of guide rails, can solve the problems of aggravating the poor operation of the movable beam and the stuck, and achieve the effect of preventing damage to the mold and ensuring the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Best practice:

[0032] The present invention will be described in more detail below in conjunction with the accompanying drawings.

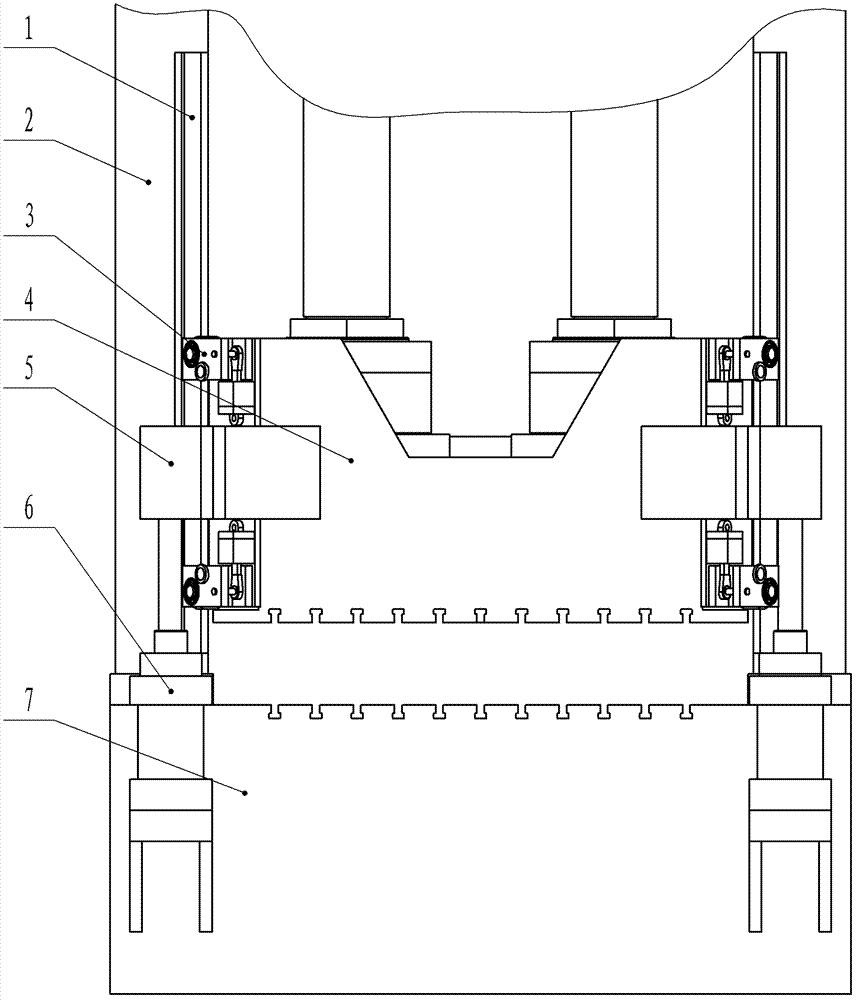

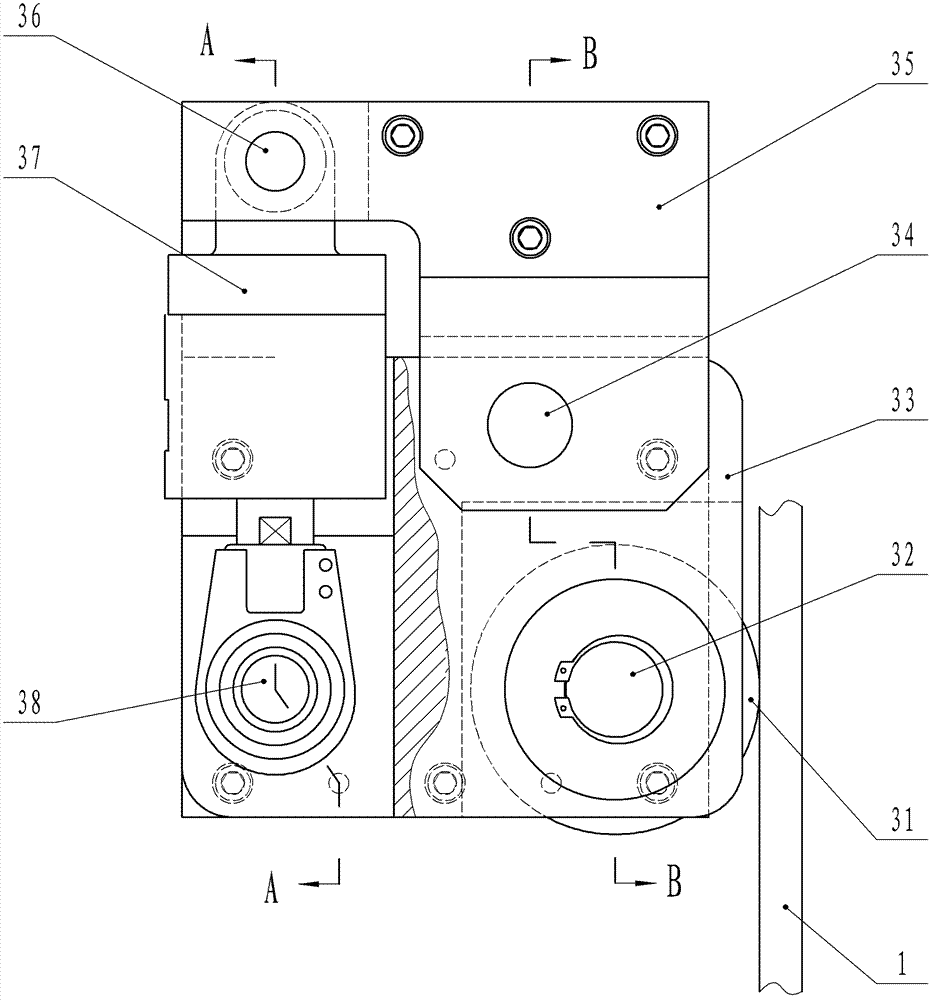

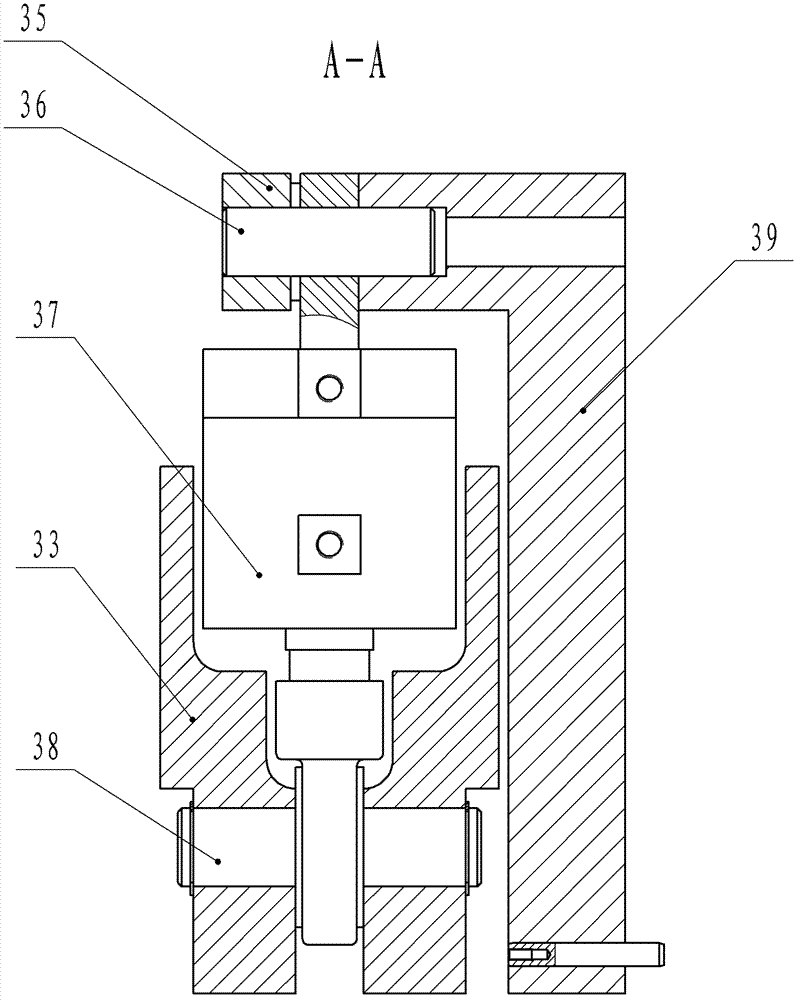

[0033] refer to figure 1 , figure 2 as well as image 3 , a floating guide device applied to a long-stroke hydraulic machine, including a guide rail 1 and a moving part 3 that guides and moves on the guide rail. The moving part 3 includes a support, a pre-tensioning mechanism 37, a displacement adjustment mechanism 33 and a roller. A support 39 and a second support 35 are fastened and connected; the pre-tightening mechanism 37 is a hydraulic cylinder, and the rodless end of the hydraulic cylinder is hinged on the first support 39 through the first hinge shaft 36 as the rear clevis shaft , the rod end of the hydraulic cylinder is hinged on the displacement adjustment mechanism 33 through the second articulation shaft 38 as the front clevis shaft; On the second bearing 35, meanwhile, this swing seat is also hinged with the roller 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com