Fountain solution centralized allocation and supply circular cooling device

A technology of circulating cooling and dampening solution, which is applied to lithographic rotary printing machines, printing, rotary printing machines, etc., can solve the problems of standardized production and affect the cleanliness of the production site, and achieve the realization of enterprise intelligence and good scalability And practicability, the effect of saving hardware space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1. A cooling device for centralized distribution and supply of dampening solution, which is characterized in that it includes a mechanical part and an electrical control part, and the electrical control part controls the mechanical part.

Embodiment 2

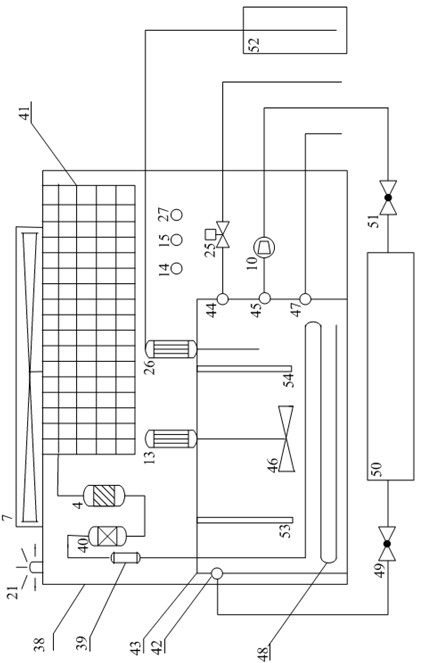

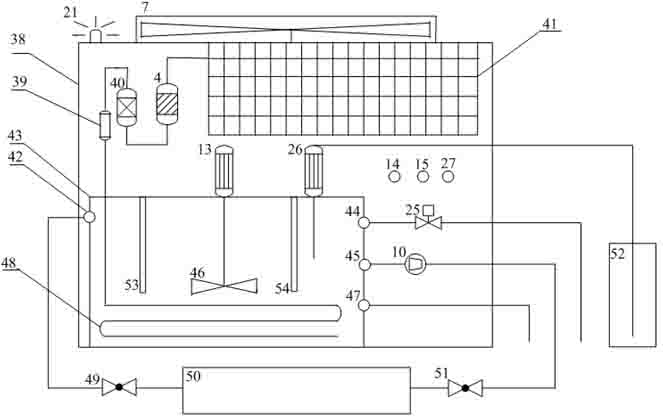

[0029] Embodiment 2, a dampening solution centralized supply circulation cooling device, the mechanical part includes a centralized distribution supply circulation cooling device box 38, a filter 39, a liquid storage tank 40, a condenser 41, a liquid return port 42, and a water tank box 43. Water supply port 44, liquid outlet port 45, stirring paddle 46, drain port 47, heat exchange coil 48, water return valve 49, terminal equipment 50, water inlet valve 51, fountain solution stock solution tank 52, temperature probe 53 And liquid level probe 54; Wherein: on the water tank body 43, there are liquid return port 42, replenishment port 44, liquid outlet 45, drain port 47; Into the inside of the water tank body 43, the liquid inlet pump 26 is installed on the water tank body 43, one end is connected to the dampening solution stock solution tank 52 through a pipeline, and the other end extends into the water tank body 43 through a pipeline, and one end of the M1 compressor 4 passes ...

Embodiment 3

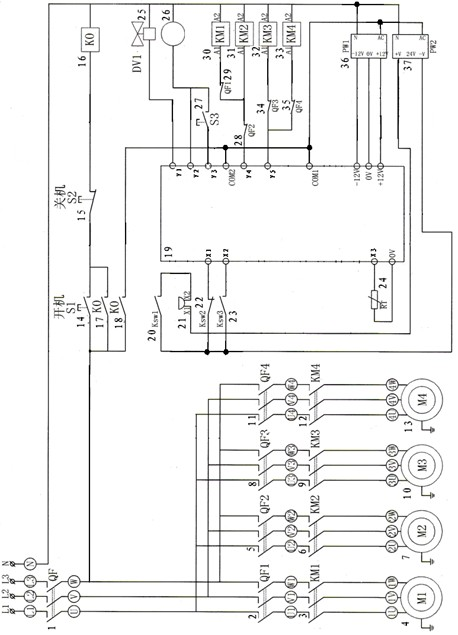

[0030] Embodiment 3, a cooling device for central distribution and supply of fountain solution, including electrical parts, wherein: the three-phase power supply L1, L2, L3 successively passes through QF circuit breaker 1, QF1 circuit breaker 2, and KM1 AC contactor contact 3 Connect to the 1U, 1V, and 1W terminals of M1 compressor 4, and ground the shell of M1 compressor 4, thereby completing the laying of the main circuit of M1 compressor 4; the three-phase power supply L1, L2, and L3 are successively disconnected through QF circuit breaker 1 and QF2 Connector 5, KM2 AC contactor contact 6 to the 2U, 2V, 2W terminals of M2 fan 7, and the shell of M2 fan 7 is grounded, thus completing the laying of the main circuit of M2 fan 7; the three-phase power supply L1, L2, L3 passes through The QF3 circuit breaker 8 and the KM3 AC contactor contact 9 are connected to the 3U, 3V, and 3W terminals of the M3 water pump 10, thereby completing the laying of the main circuit of the M3 water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com