Mounting structure of doorframe sealing strip

A technology for installation structure and sealing strip, applied in sealing device, engine sealing, transportation and packaging, etc., can solve the problems of door frame sealing strip 50 processing error assembly error, sealing performance reduction, sealing performance reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

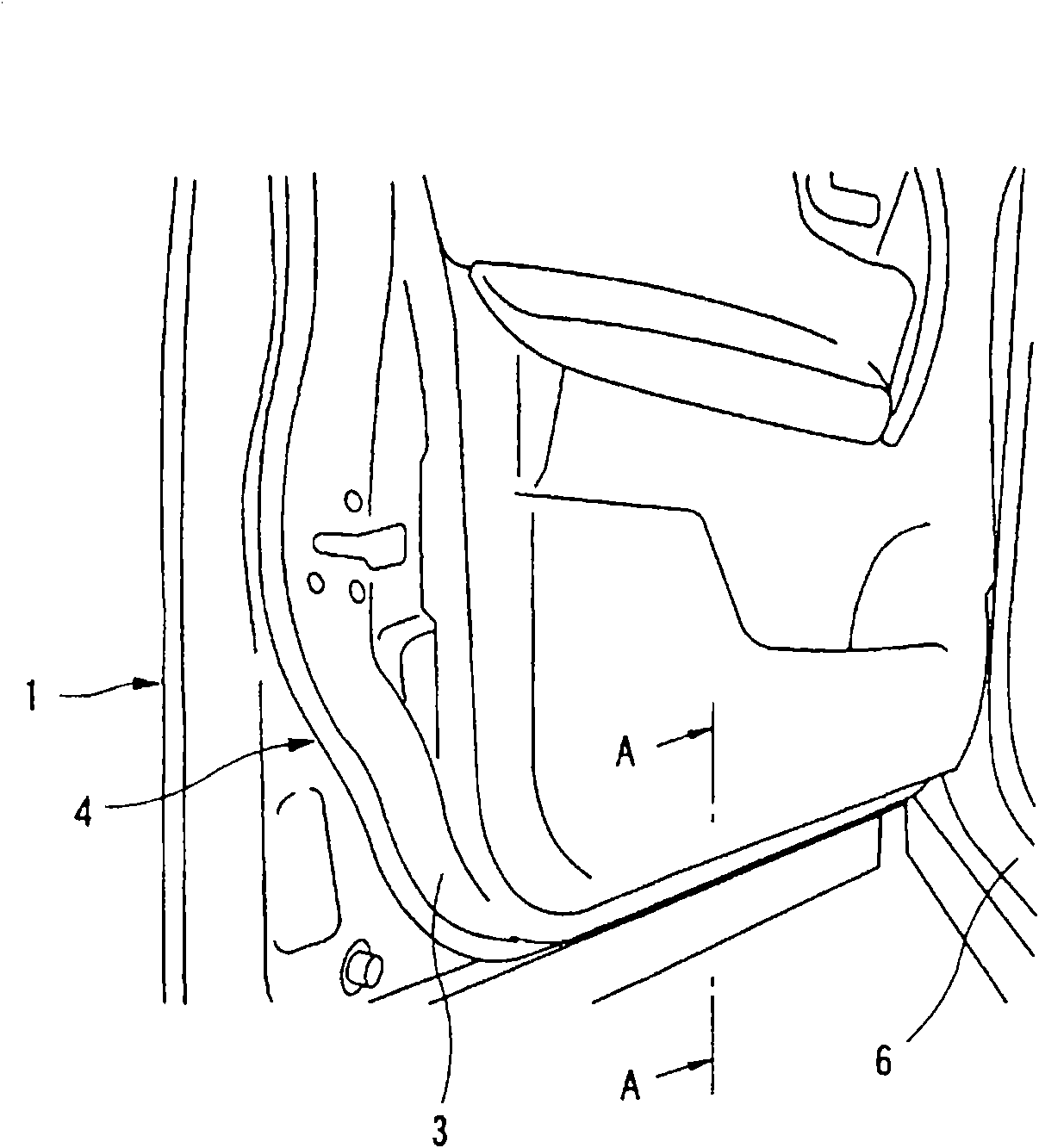

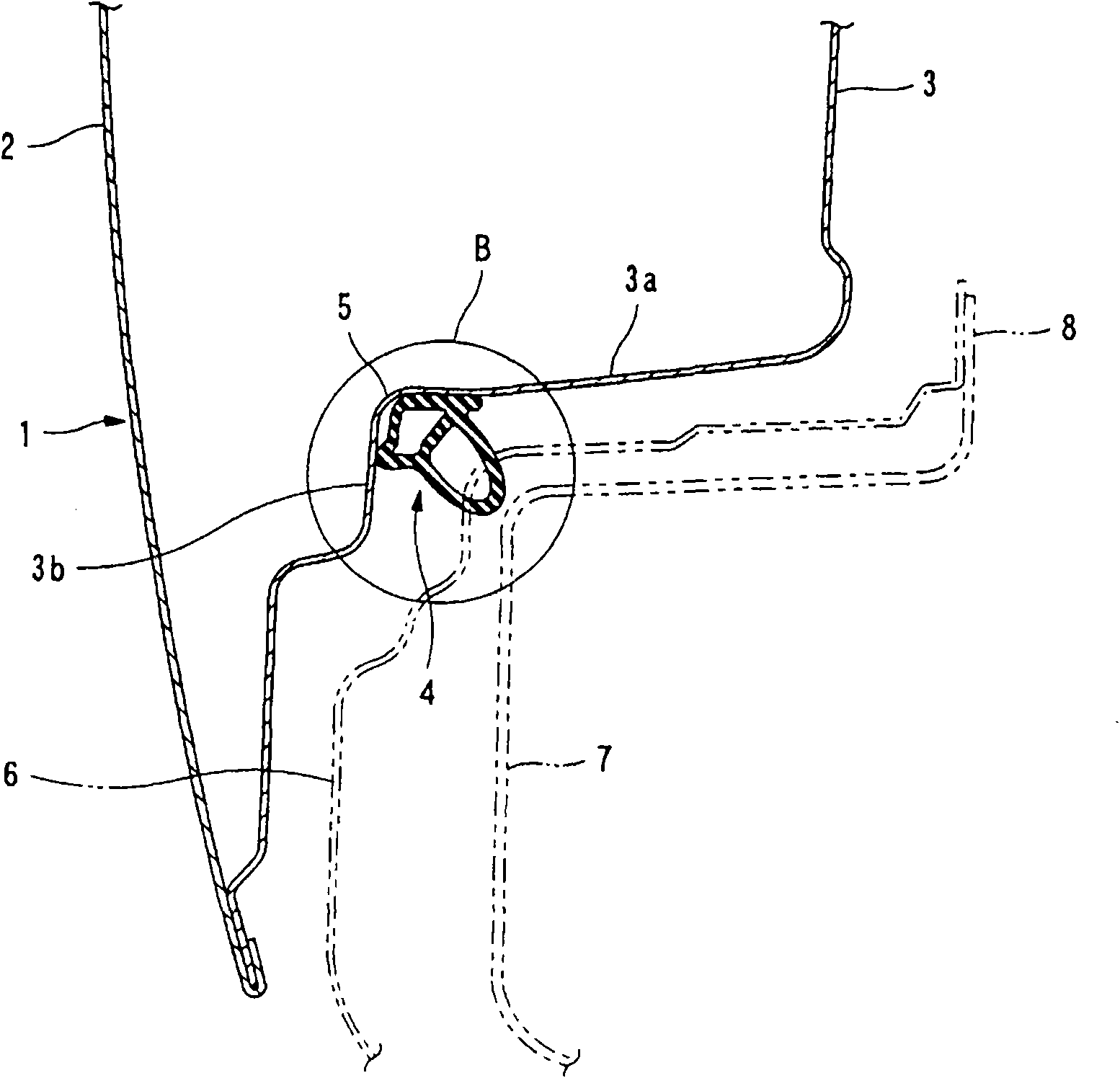

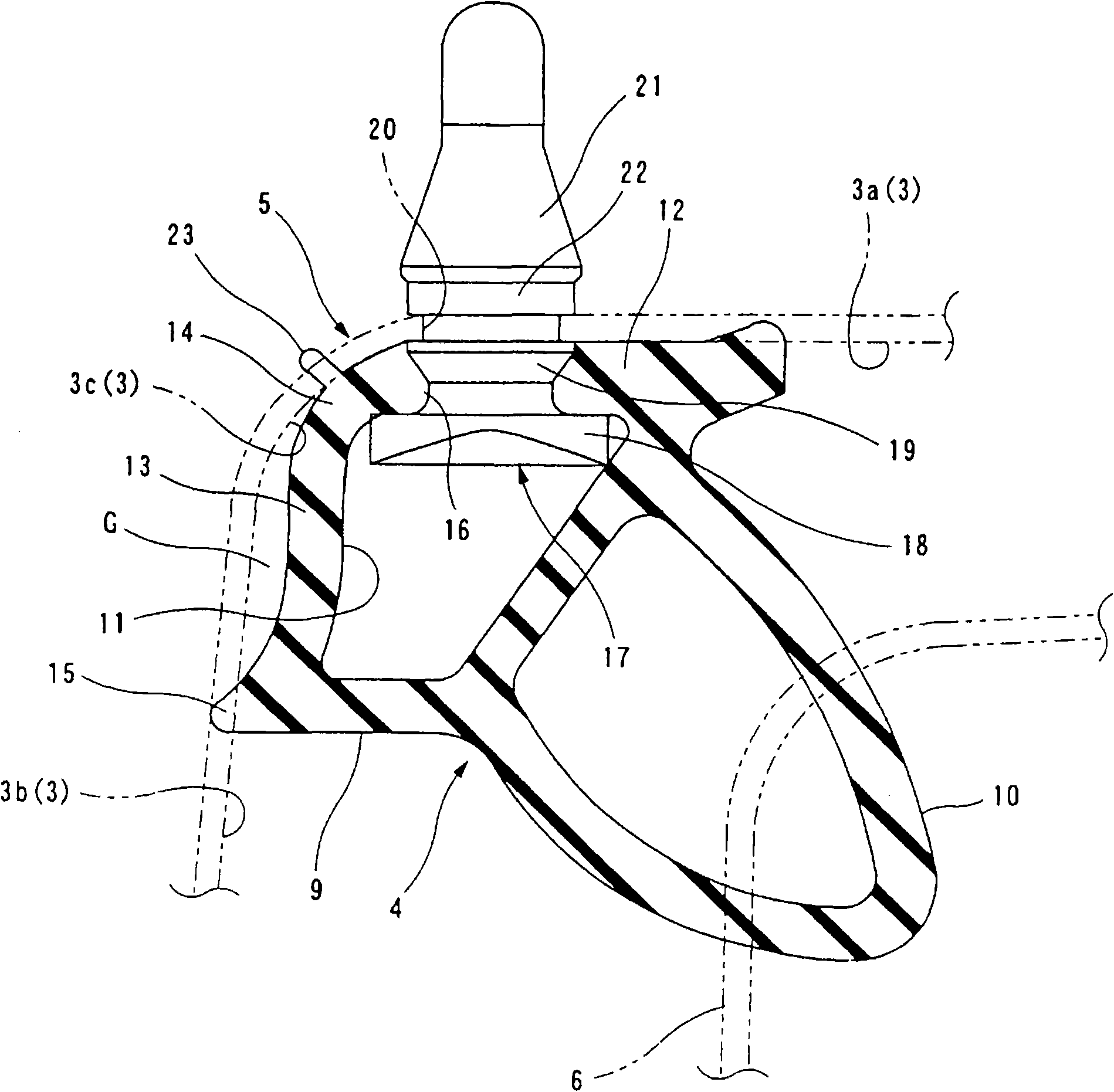

[0021] Figure 1~5 A diagram representing a more specific embodiment of the present invention, figure 1 Indicates the state of opening the hinged door 1 of the car, figure 2 Indicates that the door 1 is closed along the figure 1 An enlarged sectional view of line A-A. and then, image 3 express figure 2 Enlarged view of part B of .

[0022] like figure 1 , 2 As shown, around the inner door panel 3 forming the door 1 together with the outer door panel 2 , a long belt-shaped door frame weather strip 4 is installed in a closed loop. The door frame weather strip 4 is formed by elastic bodies such as sponge rubber, for example.

[0023] In more detail, as figure 2 As shown, at the lower part of the inner door panel 3, a wall surface 3a in the transverse direction as one wall surface and a wall surface 3b in the longitudinal direction as the other wall surface form an inner angled corner 5, and a door frame weather strip 4 is installed at the corner 5 . Furthermore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com