Electric brake boosting device

A brake booster device, an electric technology, is applied in the field of brake booster devices of automobile service brake systems, and can solve problems such as application difficulties and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

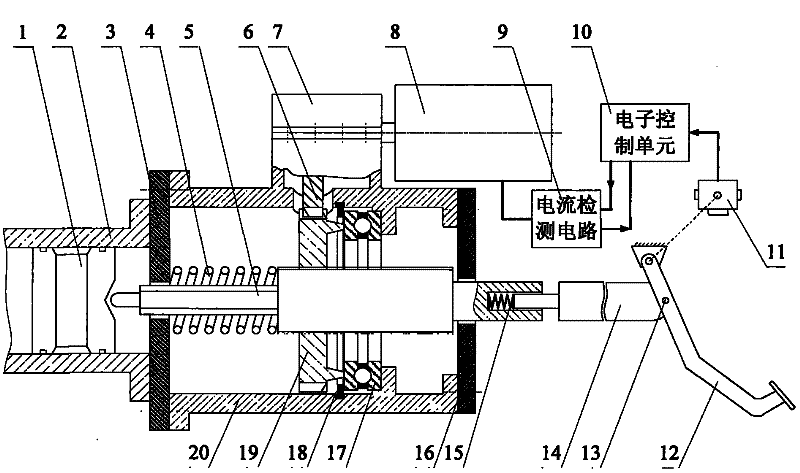

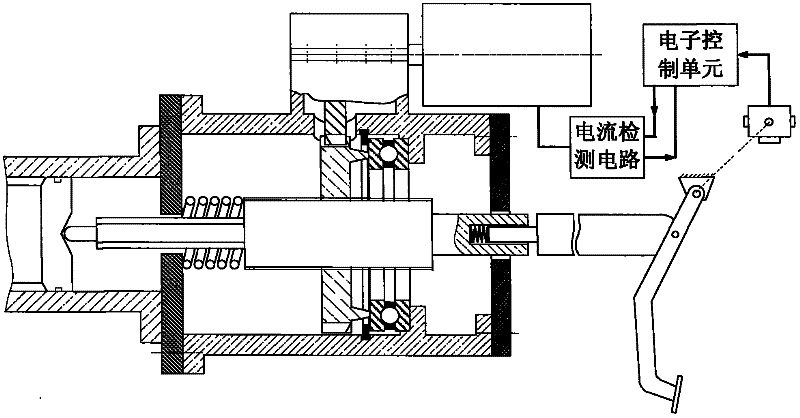

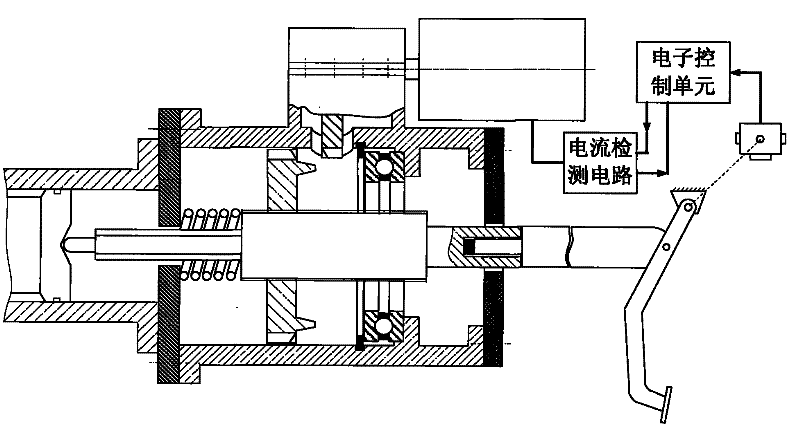

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] like figure 1 As shown, an electric brake booster is composed of a mechanical device and an electronic control system, wherein the mechanical device mainly includes a booster body, a threaded transmission mechanism and a reduction mechanism 7, and the booster body is composed of a booster housing 20, a booster The cylindrical cavity surrounded by the front end cover 3 of the booster and the rear end cover 16 of the booster has a built-in booster screw 5 processed with external threads, and the booster screw 5 cooperates with a booster gear 19 processed with internal threads to form a threaded transmission mechanism. The input of the reduction mechanism 7 comes from the stepping motor 8 of the electronic control system, and the output gear 6 of the reduction mechanism drives the power assist gear 19 through tooth meshing. The electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com