Permanent antistatic PA66/POE (Polyamide 66/Polyolefin Elastomer) alloy and preparation method thereof

A PA66, antistatic technology, used in the field of permanent antistatic masterbatch and preparation, can solve the problem of low conductivity, and achieve the effect of low cost, good compatibility and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

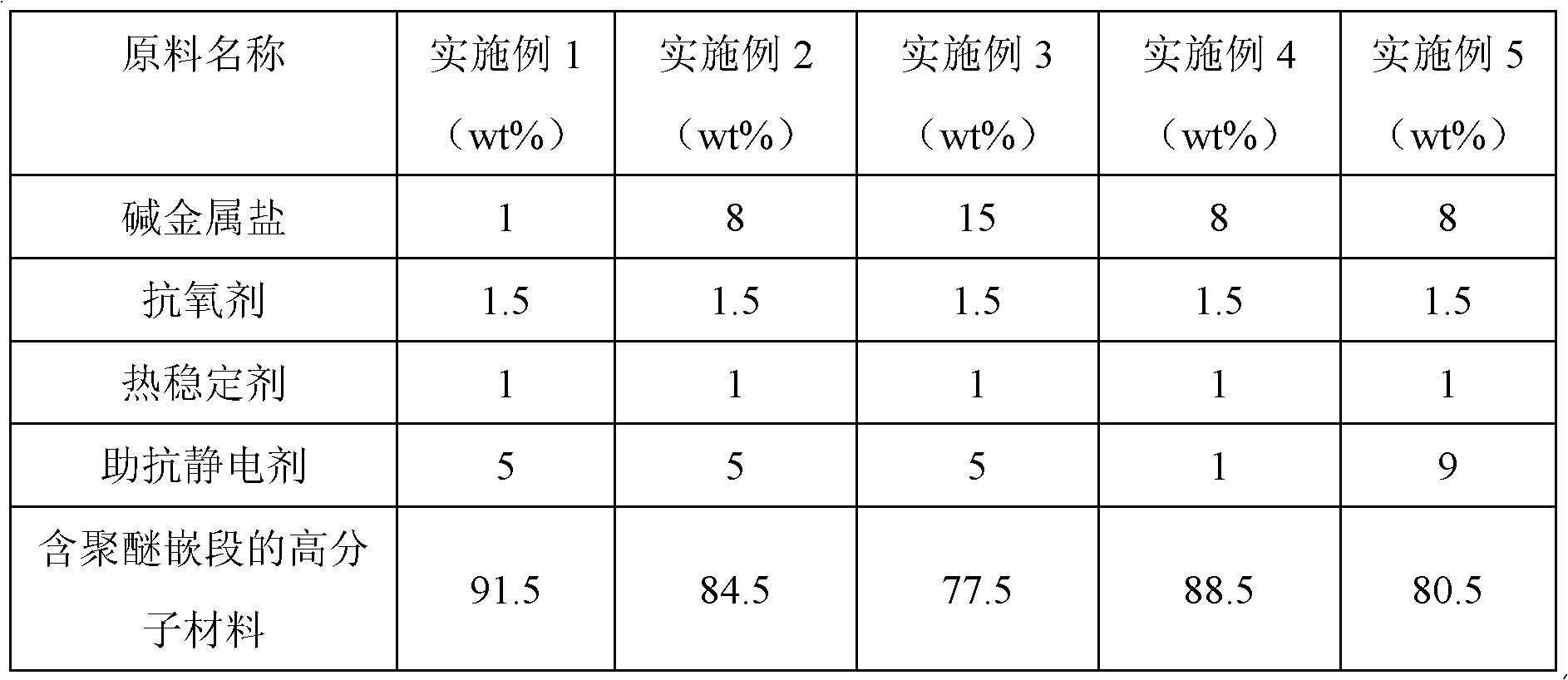

[0024] The permanent antistatic masterbatch raw material formula of embodiment 1-5 is as follows:

[0025]

[0026] In the above-mentioned Examples 1-5, the antistatic masterbatch includes the following components and weight percentages: 1-15% of alkali metal salt, 0.1-2% of antioxidant, 0.1-2% of heat stabilizer, auxiliary antioxidant Static agent 0-10%, polymer material containing polyether block 70-95%.

[0027] In above-mentioned embodiment 1-5, described alkali metal salt is M + x - , where M + for Li + , Na + , K + ;X - for Cl - 、Br - , I - 、CLO 4 - . LiCLO is preferred 4 .

[0028] In the above-mentioned Examples 1-5, the antioxidant is a compound of phenothiazine and phosphite (s9228) in a weight ratio of 1:1;

[0029] In above-mentioned embodiment 1-5, described thermostabilizer is the compound of organotin thermostabilizer, calcium stearate, zinc stearate by weight ratio 2: 1: 1;

[0030] In above-mentioned embodiment 1-5, described auxiliary antis...

Embodiment 5

[0038] Example 5 has the lowest surface resistivity and the highest cost performance.

Embodiment 6

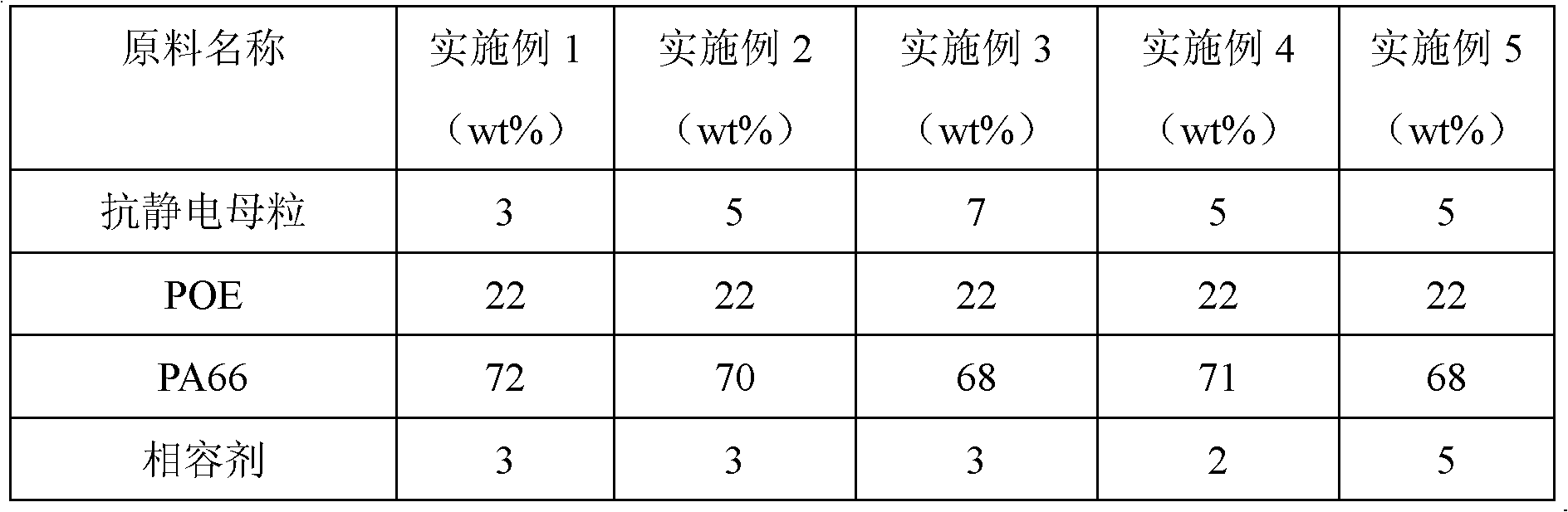

[0053] Preparation method of permanent antistatic PA66 / POE alloy:

[0054] Weigh the raw materials according to the weight ratio: 2% of the above-mentioned antistatic masterbatch, PA6672%, POE 22%, 4% compatibilizer, weigh the raw materials according to the weight ratio and put them in the high mixer for 2-5 minutes, The material is discharged, and then extruded and granulated with a twin-screw extruder, the processing temperature is 210-225°C, and the screw rotation speed is 40HZ. The surface resistivity of the prepared material is 10 10 Ω.m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com